40 - Vacuum Clamping System, страница 23

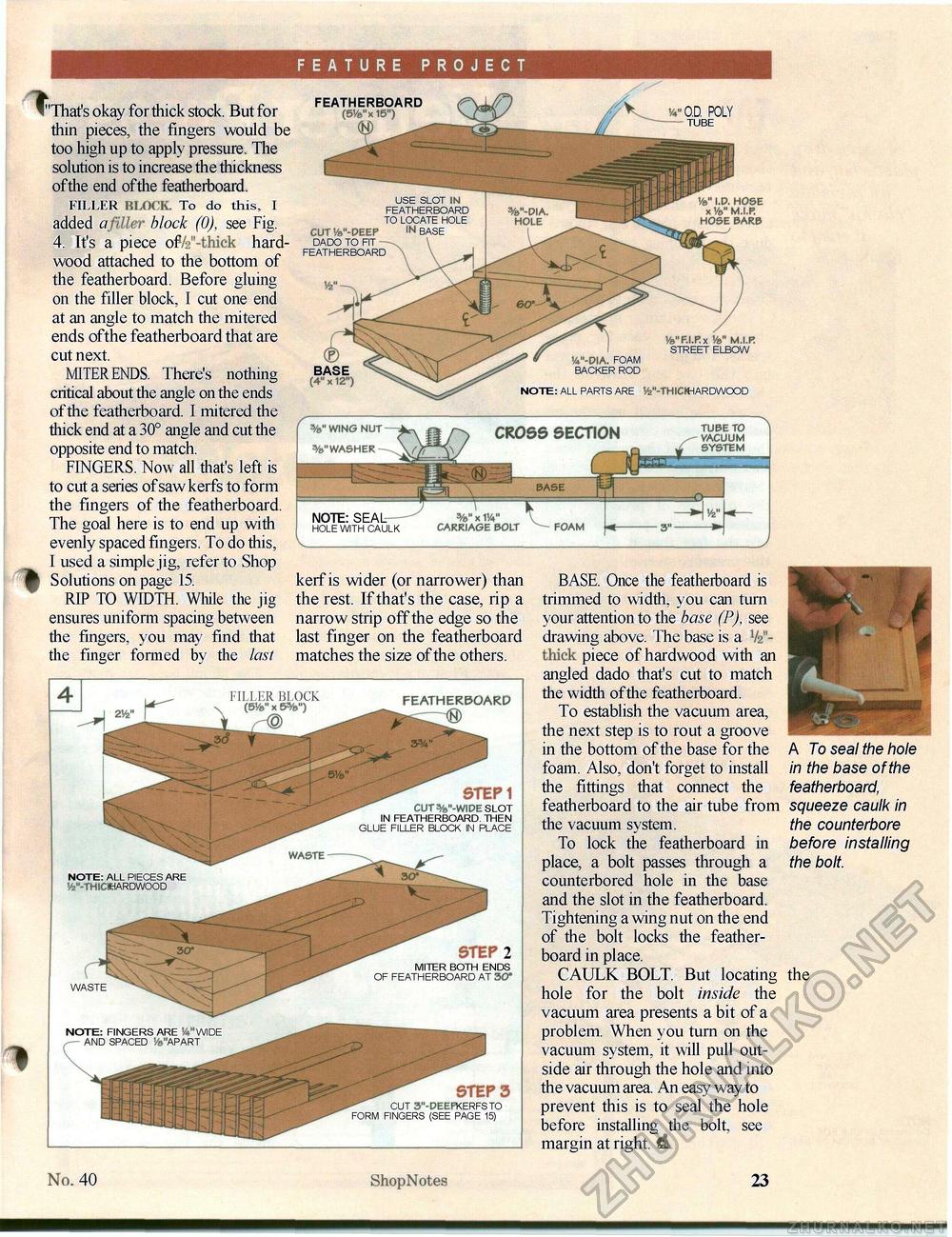

FEATURE PROJECT "That's okay for thick stock. But for thin pieces, the fingers would be too high up to apply pressure. The solution is to increase the thickness ofthe end ofthe featherboard. FILLER BLOCK. To do this, I added afiller block (0), see Fig. 4. It's a piece ofW-thick hardwood attached to the bottom of the featherboard. Before gluing on the filler block, I cut one end at an angle to match the mitered ends ofthe featherboard that are cut next. MITER ENDS. There's nothing critical about the angle on the ends of the featherboard. I mitered the thick end at a 30° angle and cut the opposite end to match. FINGERS. Now all that's left is to cut a series of saw kerfs to form the fingers of the featherboard. The goal here is to end up with evenly spaced fingers. To do this, I used a simple jig, refer to Shop Solutions on page 15. RIP TO WIDTH. While the jig ensures uniform spacing between the fingers, you may find that the finger formed by the last featherboard (51/e"x 15"; O.D. POLY TUBE note: SEAL HOLE WITH CAULK %" x W CARRIAGE BOLT FOAM kerf is wider (or narrower) than the rest. If that's the case, rip a narrow strip off the edge so the last finger on the featherboard matches the size of the others. BASE. Once the featherboard is trimmed to width, you can turn your attention to the base (P), see drawing above. The base is a V2"-thick piece of hardwood with an angled dado that's cut to match the width ofthe featherboard. To establish the vacuum area, the next step is to rout a groove in the bottom of the base for the foam. Also, don't forget to install the fittings that connect the featherboard to the air tube from the vacuum system. To lock the featherboard in place, a bolt passes through a counterbored hole in the base and the slot in the featherboard. Tightening a wing nut on the end of the bolt locks the feather-board in place. CAULK BOLT. But locating hole for the bolt inside the vacuum area presents a bit of a problem. When you turn on the vacuum system, it will pull outside air through the hole and into the vacuum area. An easy way to prevent this is to seal the hole before installing the bolt, see margin at right. & A To seal the hole in the base of the featherboard, squeeze caulk in the counterbore before installing the bolt. the 18 ShopNotes 40 |