40 - Vacuum Clamping System, страница 20

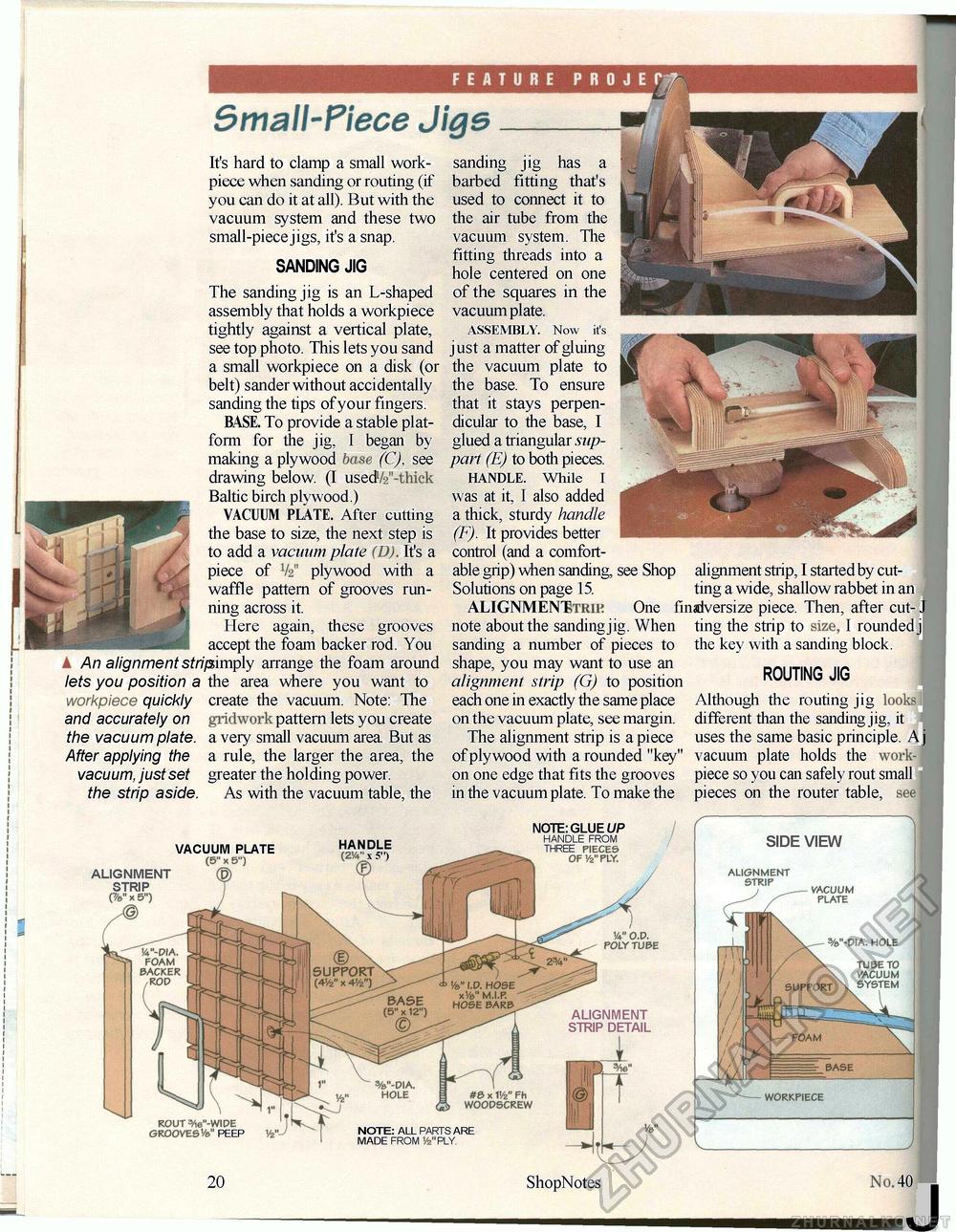

tightly against a vertical plate, see top photo. This lets you sand a small workpiece on a disk (or belt) sander without accidentally sanding the tips of your fingers. BASE. To provide a stable platform for the jig, I began by making a plywood base (C), see drawing below. (I usedW'-thick Baltic birch plywood.) VACUUM PLATE. After cutting the base to size, the next step is to add a vacuum plate (D). It's a piece of V2" plywood with a waffle pattern of grooves running across it. Here again, these grooves accept the foam backer rod. You A An alignment stripsimply arrange the foam around lets you position a the area where you want to workpiece quickly create the vacuum. Note: The and accurately on gridwork pattern lets you create the vacuum plate, a very small vacuum area But as After applying the a rule, the larger the area, the vacuum, just set greater the holding power. the strip aside. As with the vacuum table, the ASSEMBLY. Now it's just a matter of gluing the vacuum plate to the base. To ensure that it stays perpendicular to the base, I glued a triangular sup-part (E) to both pieces. handle. While I was at it, I also added a thick, sturdy handle (F). It provides better control (and a comfortable grip) when sanding, see Shop alignment strip, I started by cut-Solutions on page 15. ting a wide, shallow rabbet in an ALIGNMENItrie One finadversize piece. Then, after cut-. note about the sanding jig. When ting the strip to size, I rounded j sanding a number of pieces to shape, you may want to use an alignment strip (G) to position each one in exactly the same place on the vacuum plate, see margin. The alignment strip is a piece of plywood with a rounded "key" on one edge that fits the grooves in the vacuum plate. To make the the key with a sanding block. ROUTING JIG Although the routing jig looks different than the sanding jig, it uses the same basic principle. Aj vacuum plate holds the work-piece so you can safely rout small pieces on the router table, see ALIGNMENT STRIP (%" x 5") vacuum plate (5" x 5") 15: handle (214" x 5") note: glue UP HANDLE FROM THREE PIECES OF Vz" PLY. ROUT =/i6"-WIDE PEEP 26 ShopNotes SIDE VIEW ALIGNMENT STRIP / VACUUM PLATE - %"-DIA. HOLE TUBE TO VACUUM SUPPORT \ SYSTEM - BASE WORKPIECE 40 40 |

||||||||