41 - Fold-Down Drafting Table, страница 24

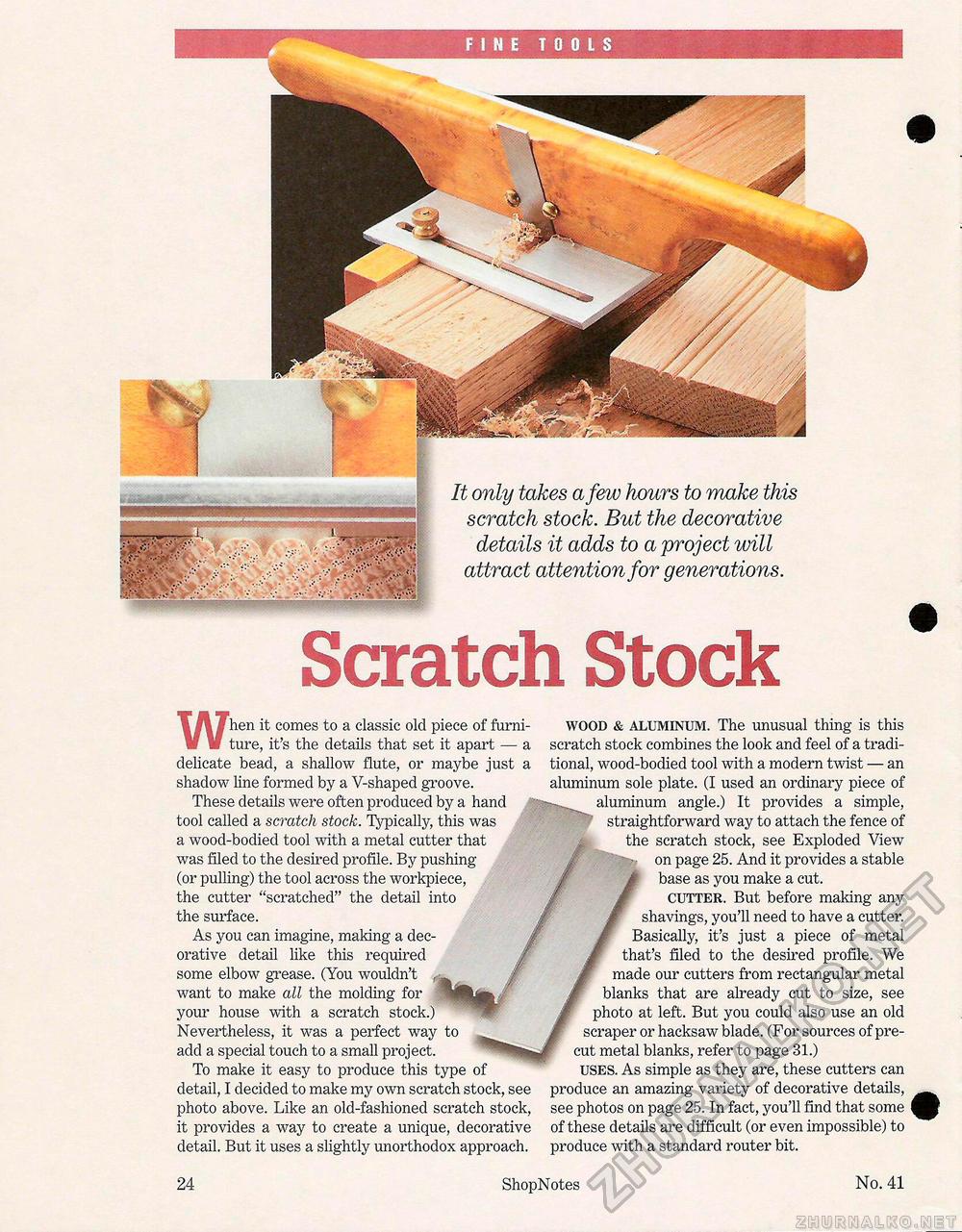

FINE TOOLS It only takes a few hours to make this scratch stock. But the decorative details it adds to a project will attract attention for generations. Scratch Stock When it comes to a classic old piece of furniture, it's the details that set it apart — a delicate bead, a shallow flute, or maybe just a shadow line formed by a V-shaped groove. These details were often produced by a hand tool called a scratch stock. Typically, this was a wood-bodied tool with a metal cutter that was filed to the desired profile. By pushing (or pulling) the tool across the workpiece, the cutter "scratched" the detail into the surface. As you can imagine, making a decorative detail like this required some elbow grease. (You wouldn't want to make all the molding for your house with a scratch stock.) Nevertheless, it was a perfect way to acid a special touch to a small project. To make it easy to produce this type of detail, I decided to make my own scratch stock, see photo above. Like an old-fashioned scratch stock, it provides a way to create a unique, decorative detail. But it uses a slightly unorthodox approach. wood & aluminum. The unusual thing is this scratch stock combines the look and feel of a traditional, wood-bodied tool with a modern twist — an aluminum sole plate. (I used an ordinary piece of aluminum angle.) It provides a simple, straightforward way to attach the fence of the scratch stock, see Exploded View on page 25. And it provides a stable base as you make a cut. cutter. But before making any shavings, you'll need to have a cutter. Basically, it's just a piece of metal that's filed to the desired profile. We made our cutters from rectangular metal blanks that are already cut to size, see photo at left. But you could also use an old scraper or hacksaw blade. (For sources of pre-cut metal blanks, refer to page 31.) uses. As simple as they are, these cutters can produce an amazing variety of decorative details, see photos on page 25. In fact, you'll find that some ^p of these details are difficult (or even impossible) to produce with a standard router bit. 24 ShopNotes No. 41 |