43 - Build Your Own Dovetail Jig, страница 14

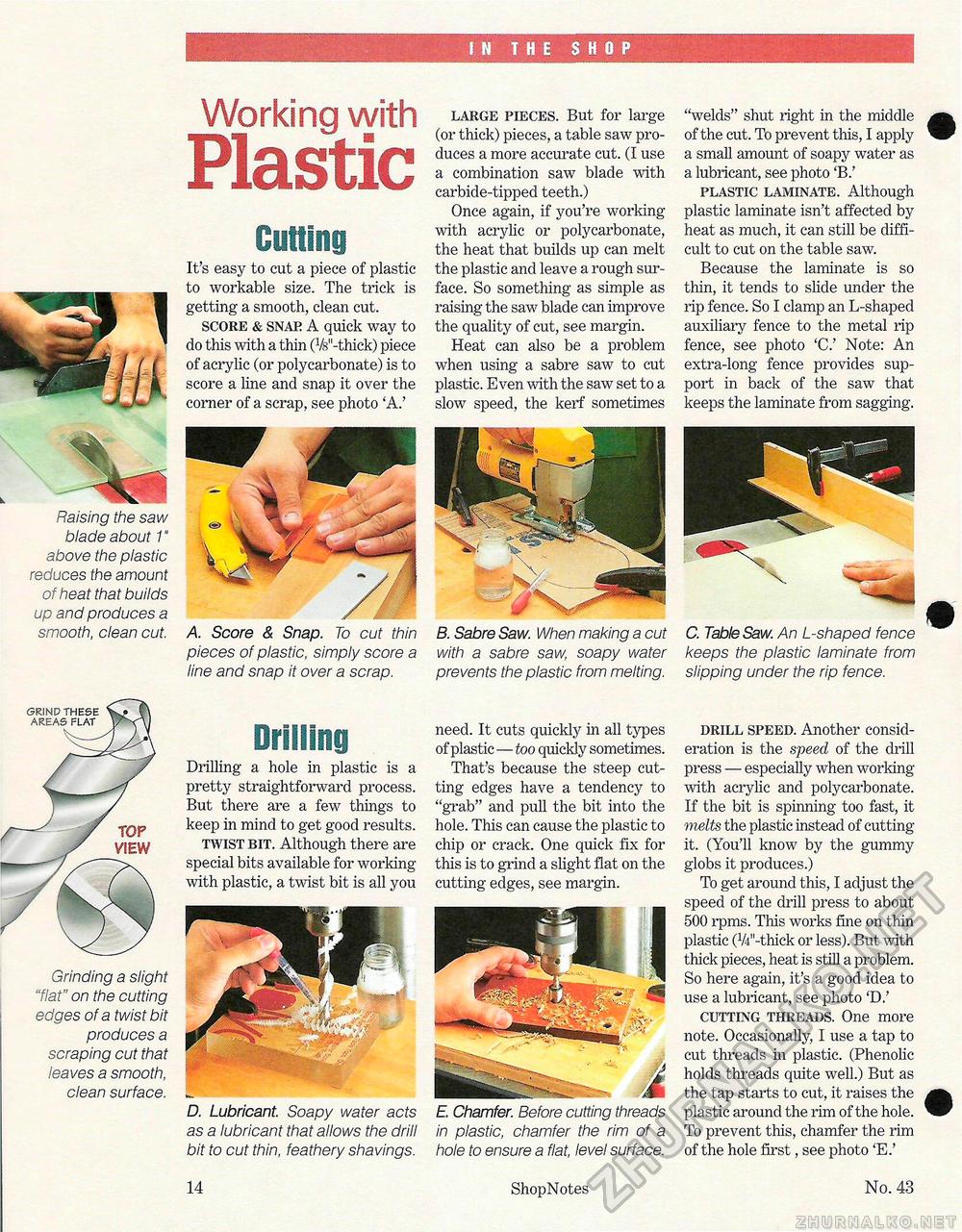

IN THE SHOP Raising the saw blade about 1" above the plastic reduces the amount of heat that builds up and produces a smooth, clean cut. Working withPlasticLARGE PIECES. But for large (or thick) pieces, a table saw produces a more accurate cut. (I use a combination saw blade with carbide-tipped teeth.) Once again, if you're working with acrylic or polycarbonate, the heat that builds up can melt the plastic and leave a rough surface. So something as simple as raising the saw blade can improve the quality of cut, see margin. Heat can also be a problem when using a sabre saw to cut plastic. Even with the saw set to a slow speed, the kerf sometimes B. Sabre Saw. When making a cut with a sabre saw, soapy water prevents the plastic from melting. "welds" shut right in the middle ^fe of the cut. To prevent this, I apply ^F a small amount of soapy water as a lubricant, see photo 'B.' plastic laminate. Although plastic laminate isn't affected by heat as much, it can still be difficult to cut on the table saw. Because the laminate is so thin, it tends to slide under the rip fence. So I clamp an L-shaped auxiliary fence to the metal rip fence, see photo 'C.' Note: An extra-long fence provides support in back of the saw that keeps the laminate from sagging. C. Table Saw. An L-shaped fence keeps the plastic laminate from slipping under the rip fence. CuttingIt's easy to cut a piece of plastic to workable size. The trick is getting a smooth, clean cut. score & snap A quick way to do this with a thin (Vs'-thick) piece of acrylic (or polycarbonate) is to score a line and snap it over the corner of a scrap, see photo 'A.' A. Score & Snap. To cut thin pieces of plastic, simply score a line and snap it over a scrap. Grinding a slight "flat" on the cutting edges of a twist bit produces a scraping cut that leaves a smooth, clean surface. drill speed. Another consideration is the speed of the drill press — especially when working with acrylic and polycarbonate. If the bit is spinning too fast, it melts the plastic instead of cutting-it. (You'll know by the gummy globs it produces.) To get around this, I adjust the speed of the drill press to about 500 rpms. This works fine on thin plastic (V4"-thick or less). But with thick pieces, heat is still a problem. So here again, it's a good idea to use a lubricant, see photo 'D.' cutting threads. One more note. Occasionally, I use a tap to cut threads in plastic. (Phenolic holds threads quite well.) But as the tap starts to cut, it raises the plastic around the rim of the hole. To prevent this, chamfer the rim of the hole first, see photo 'E.' DrillingD. Lubricant. Soapy water acts as a lubricant that allows the drill bit to cut thin, feathery shavings. need. It cuts quickly in all types of plastic — too quickly sometimes. That's because the steep cutting edges have a tendency to "grab" and pull the bit into the hole. This can cause the plastic to chip or crack. One quick fix for this is to grind a slight flat on the cutting edges, see margin. £ Chamfer. Before cutting threads in plastic, chamfer the rim of a hole to ensure a flat, level surface. Drilling a hole in plastic is a pretty straightforward process. But there are a few things to keep in mind to get good results. twist bit. Although there are special bits available for working with plastic, a twist bit is all you GRIND THESE AREAS FLAT TOP VIEW 14 ShopNotes No. 43 |