57 - A Shop-Built Pin Router, страница 25

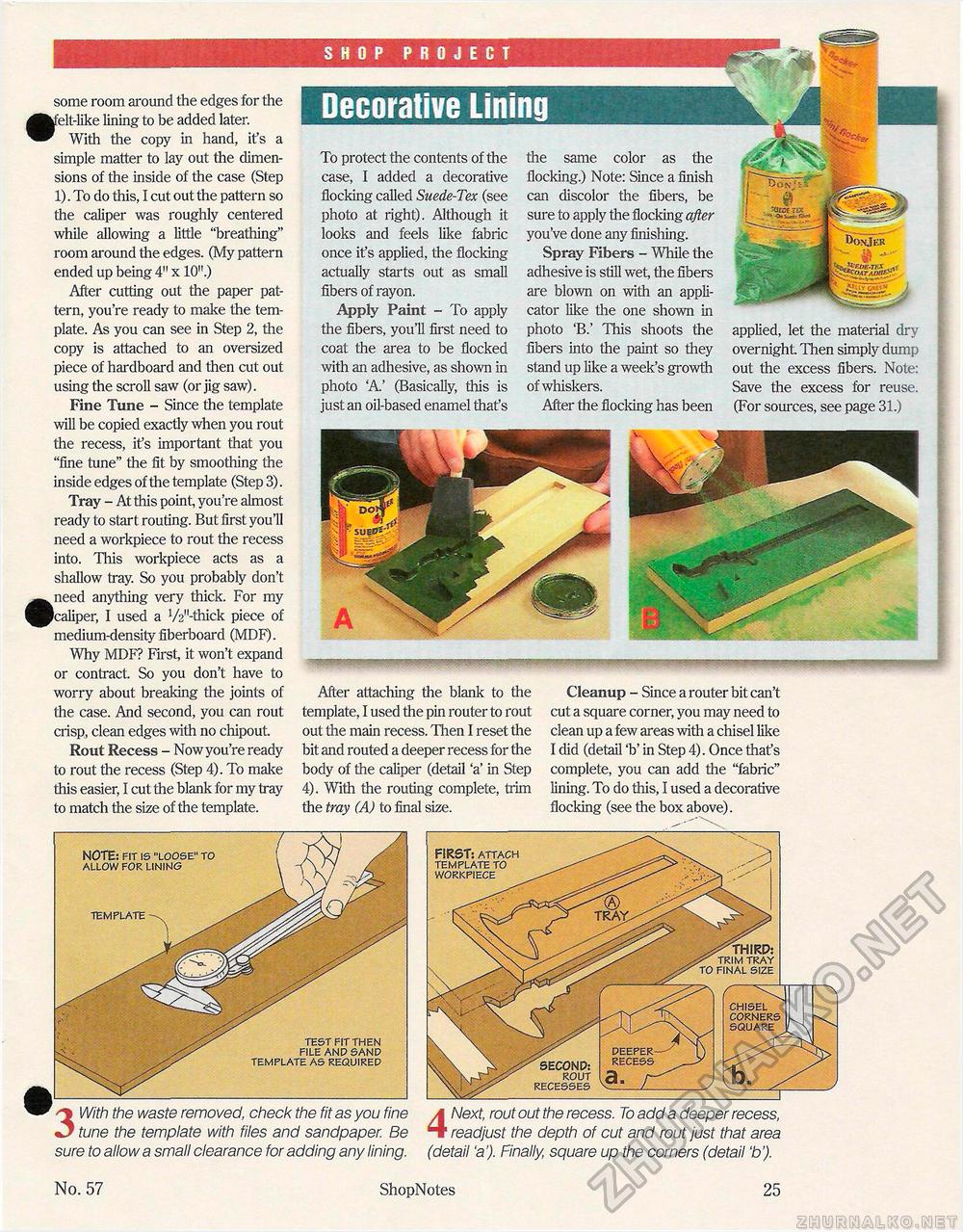

Decorative Lining To protect the contents of the case, I added a decorative flocking called Suede-Tex (see photo at right). Although it looks and feels like fabric once it's applied, the flocking actually starts out as small fibers of rayon. Apply Paint - To apply the fibers, you'll first need to coat the area to be flocked with an adhesive, as shown in photo 'A.' (Basically, this is just an oil-based enamel that's the same color as the flocking.) Note: Since a finish can discolor the fibers, be sure to apply the flocking after you've done any finishing. Spray Fibers - While the adhesive is still wet, the fibers are blown on with an applicator like the one shown in photo 'B.' This shoots the fibers into the paint so they stand up like a week's growth of whiskers. After the flocking has been applied, let the material dry overnight. Then simply dump out the excess fibers. Note: Save the excess for reuse. (For sources, see page 31.) some room around the edges for the [felt-like lining to be added later. With the copy in hand, it's a simple matter to lay out the dimensions of the inside of the case (Step 1). To do this, I cut out the pattern so the caliper was roughly centered while allowing a little "breathing" room around the edges. (My pattern ended up being 4" x 10".) After cutting out the paper pattern, you're ready to make the template. As you can see in Step 2, the copy is attached to an oversized piece of hardboard and then cut out using the scroll saw (or jig saw). Fine Tune - Since the template will be copied exactly when you rout the recess, it's important that you "fine tune" the fit by smoothing the inside edges of the template (Step 3). Tray - At this point, you're almost ready to start routing. But first you'll need a workpiece to rout the recess into. This workpiece acts as a shallow tray. So you probably don't need anything very thick. For my fcaliper, I used a V211'-thick piece of medium-density fiberboard (MDF). Why MDF? First, it won't expand or contract. So you don't have to worry about breaking the joints of the case. And second, you can rout crisp, clean edges with no chipout. Rout Recess - Now you're ready to rout the recess (Step 4). To make this easier, I cut the blank for my tray to match the size of the template. After attaching the blank to the template, I used the pin router to rout out the main recess. Then I reset the bit and routed a deeper recess for the body of the caliper (detail 'a' in Step 4). With the routing complete, trim the tray (A) to final size. Cleanup - Since a router bit can't cut a square corner, you may need to clean up a few areas with a chisel like I did (detail 'b' in Step 4). Once that's complete, you can add the "fabric" lining. To do this, I used a decorative flocking (see the box above). test fit then file and sand template as required 3 With the waste removed, check the fit as you fine tune the template with files and sandpaper. Be sure to allow a small clearance for adding any lining. template 4 Next, rout out the recess. To add a deeper recess, readjust the depth of cut and rout just that area (detail 'a'). Finally, square up the corners (detail 'b'). NOTE: fit is "loose" to allow for lining FIRST: attach template to workpiece trim tray to final size No. 57 ShopNotes 25 |