62 - Box Joint Jig, страница 22

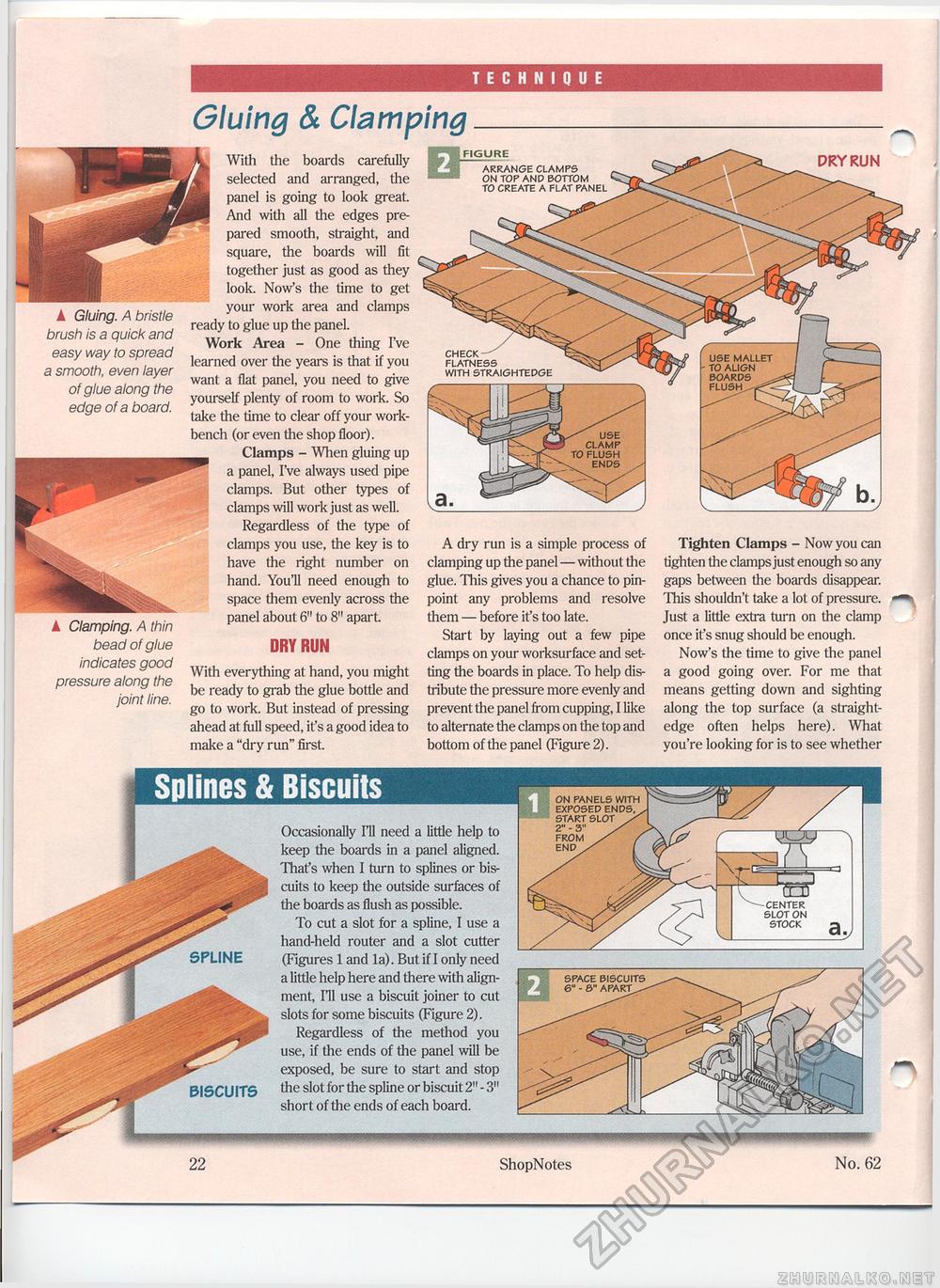

TECHNIQUE Gluing & ClampingTighten Clamps - Now you can tighten the clamps just enough so any gaps between the boards disappear. This shouldn't take a lot of pressure. Just a little extra turn on the clamp once it's snug should be enough. Now's the time to give the panel a good going over. For me that means getting down and sighting along the top surface (a straightedge often helps here). What you're looking for is to see whether DRY RUN A dry run is a simple process of clamping up the panel — without the glue. This gives you a chance to pinpoint any problems and resolve them — before ifs too late. Start by laying out a few pipe clamps on your worksurface and setting the boards in place. To help distribute the pressure more evenly and prevent the panel from cupping, I like to alternate the clamps on the top and bottom of the panel (Figure 2). ▲ Gluing. A bristle brush is a quick and easy way to spread a smooth, even layer of glue along the edge of a board. With the boards can selected and arranged, panel is going to look great And with all the edges prepared smooth, straight, and square, the boards will fit together just as good as they look. Now's the time to get your work area and clamps ready to glue up the panel. Work Area - One thing I've learned over the years is that if you want a flat panel, you need to give yourself plenty of room to work. So take the time to clear off your workbench (or even the shop floor). Clamps - When gluing up a panel, I've always used pipe clamps. But other types of clamps will work just as well. Regardless of the type of clamps you use, the key is to have the right number on hand. You'll need enough to space them evenly across the panel about 6" to 8" apart DRY RUNWith everything at hand, you might be ready to grab the glue bottle and go to work. But instead of pressing ahead at full speed, it's a good idea to make a "dry run" first. FIGURE ARRANGE CLAMPS ON TOP AND BOTTOM TO CREATE A FLAT PANEL CHECK FLATNESS WITH STRAIGHTEDGE USE CLAMP TO FLUSH ▲ Clamping. A thin bead of glue indicates good pressure along the joint line. Splines & BiscuitsSPLINE BISCUITS Occasionally 111 need a little help to keep the boards in a panel aligned. Thafs when I turn to splines or biscuits to keep the outside surfaces of the boards as flush as possible. To cut a slot for a spline, I use a hand-held router and a slot cutter (Figures 1 and la). But if I only need a little help here and there with alignment 111 use a biscuit joiner to cut slots for some biscuits (Figure 2). Regardless of the method you use, if the ends of the panel will be exposed, be sure to start and stop the slot for the spline or biscuit 2" - 3" short of the ends of each board. ON PANELS WITH EXPOSED ENDS. START SLOT 2" - 3" FROM END SPACE BISCUITS 6" - »" 62 22 ShopNotes No. _____ |