62 - Box Joint Jig, страница 34

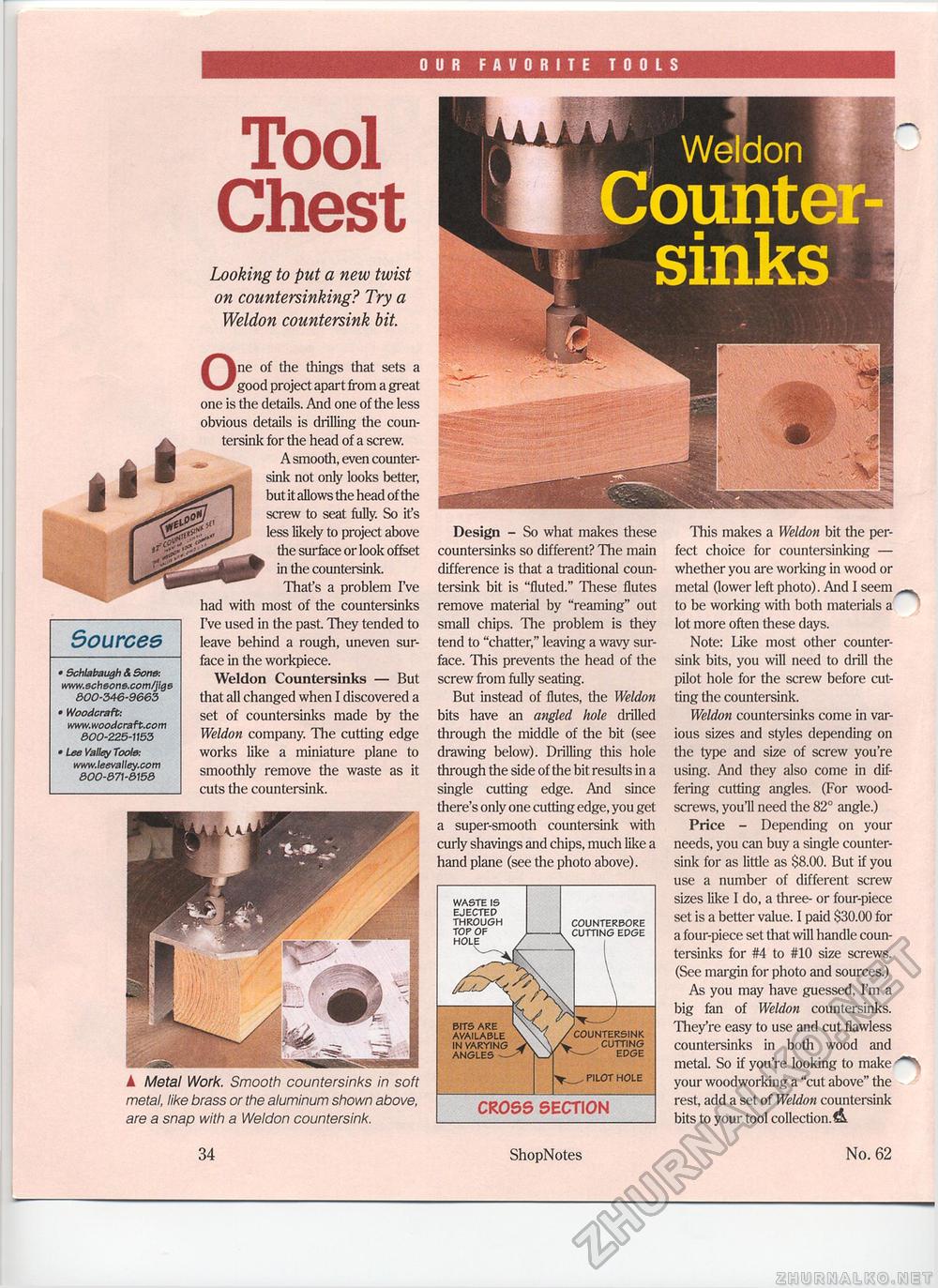

OUR FAVORITE TOOLS Sources • Schtabaugh & Sons: www.scheons.com/Jigs aOO-346-9665 • Woodcraft: www.woodcraft.com 300-225-1153 • Lee Valley Toole: www.leevalley.com 000-071-0153 One of the things that sets a good project apart from a great one is the details. And one of the less obvious details is drilling the countersink for the head of a screw. A smooth, even countersink not only looks better, but it allows the head of the screw to seat My. So ifs less likely to project above the surface or look offset in the countersink. That's a problem I've had with most of the countersinks I've used in the past. They tended to leave behind a rough, uneven surface in the workpiece. Weldon Countersinks — But that all changed when I discovered a set of countersinks made by the Weldon company. The cutting edge works like a miniature plane to smoothly remove the waste as it cuts the countersink. Design - So what makes these countersinks so different? The main difference is that a traditional countersink bit is "fluted." These flutes remove material by "reaming" out small chips. The problem is they tend to "chatter," leaving a wavy surface. This prevents the head of the screw from fully seating. But instead of flutes, the Weldon bits have an angled hole drilled through the middle of the bit (see drawing below). Drilling this hole through the side of the bit results in a single cutting edge. And since there's only one cutting edge, you get a super-smooth countersink with curly shavings and chips, much like a hand plane (see the photo above). This makes a Weldon bit the perfect choice for countersinking — whether you are working in wood or metal (lower left photo). And I seem to be working with both materials a lot more often these days. Note: Like most other countersink bits, you will need to drill the pilot hole for the screw before cutting the countersink. Weldon countersinks come in various sizes and styles depending on the type and size of screw you're using. And they also come in differing cutting angles. (For wood-screws, you'll need the 82° angle.) Price - Depending on your needs, you can buy a single countersink for as little as $8.00. But if you use a number of different screw sizes like I do, a three- or four-piece set is a better value. I paid $30.00 for a four-piece set that will handle countersinks for #4 to #10 size screws. (See margin for photo and sources.) As you may have guessed, I'm a big fan of Weldon countersinks. They're easy to use and cut flawless countersinks in both wood and metal. So if you're looking to make your woodworking a "cut above" the rest, add a set of Weldon countersink bits to your tool collection. & A Metal Work. Smooth countersinks in soft metal, like brass or the aluminum shown above, are a snap with a Weldon countersink. Tool ChestLooking to put a new twist on countersinking? Try a Weldon countersink bit. CROSS SECTION waste is ejected through top of BITS ARE AVAILABLE IN VARYING ANGLES counterbore fitting edge _, PILOT HOLE COUNTERSINK CUTTING EDGE 34 ShopNotes No. 62 |