62 - Box Joint Jig, страница 33

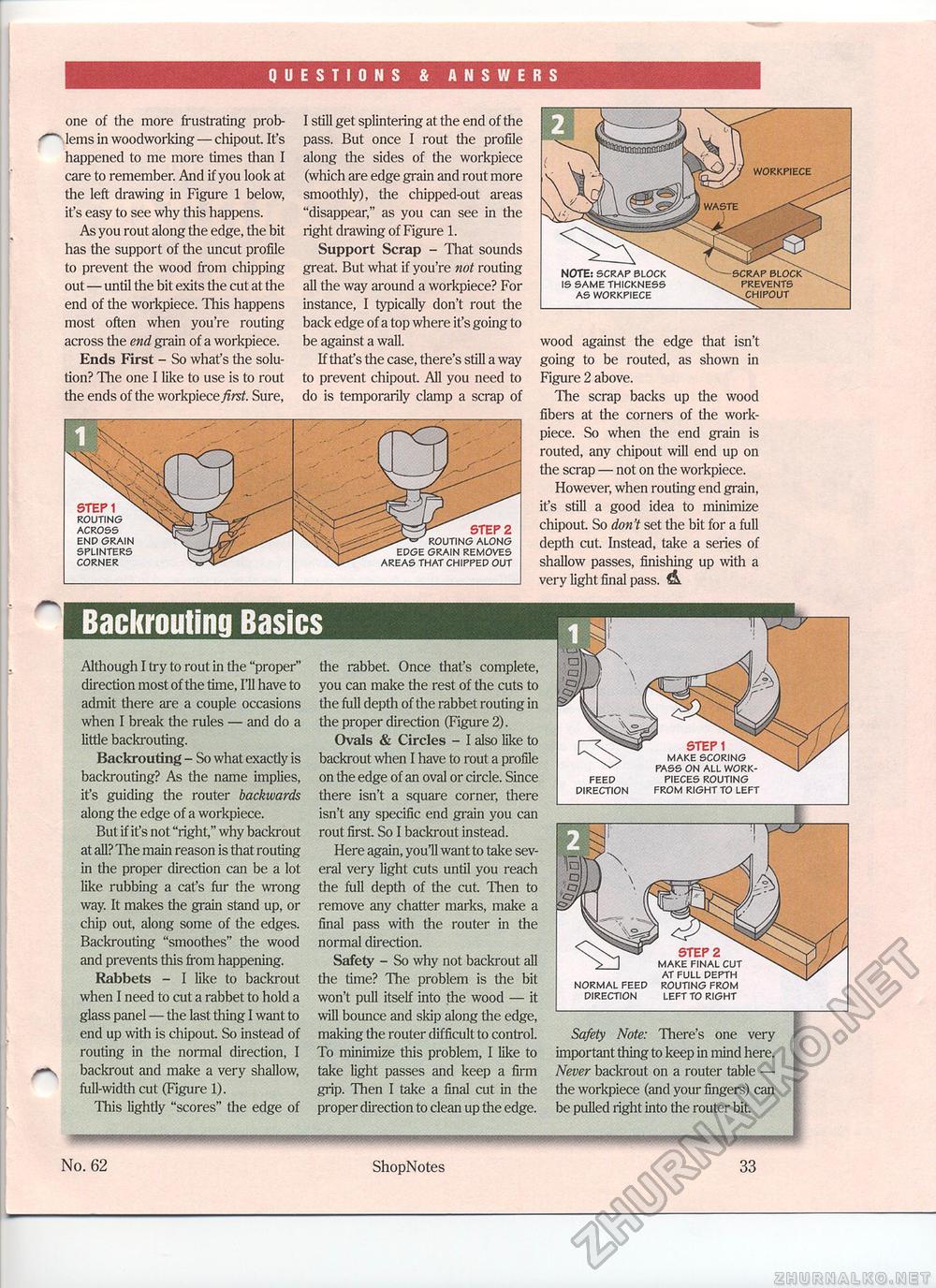

QUESTIONS & ANSWERS one of the more frustrating problems in woodworking — chipout. It's happened to me more times than I care to remember. And if you look at the left drawing in Figure 1 below, it's easy to see why this happens. As you rout along the edge, the bit has the support of the uncut profile to prevent the wood from chipping out—until the bit exits the cut at the end of the workpiece. This happens most often when you're routing across the end grain of a workpiece. Ends First - So whaf s the solution? The one I like to use is to rout the ends of the workpiece first. Sure, I still get splintering at the end of the pass. But once I rout the profile along the sides of the workpiece (which are edge grain and rout more smoothly), the chipped-out areas "disappear," as you can see in the right drawing of Figure 1. Support Scrap - That sounds great. But what if you're not routing all the way around a workpiece? For instance, I typically don't rout the back edge of a top where it's going to be against a wall. If that's the case, there's still a way to prevent chipout All you need to do is temporarily clamp a scrap of wood against the edge that isn't going to be routed, as shown in Figure 2 above. The scrap backs up the wood fibers at the corners of the work-piece. So when the end grain is routed, any chipout will end up on the scrap — not on the workpiece. However, when routing end grain, it's still a good idea to minimize chipout. So don't set the bit for a full depth cut. Instead, take a series of shallow passes, finishing up with a very light final pass. Backrouting Basics Although I try to rout in the "proper" direction most of the time, I'll have to admit there are a couple occasions when I break the rules — and do a little backrouting. Backrouting - So what exactly is backrouting? As the name implies, it's guiding the router backwards along the edge of a workpiece. But if it's not "right," why backrout at all? The main reason is that routing in the proper direction can be a lot like rubbing a cat's fur the wrong way. It makes the grain stand up, or chip out, along some of the edges. Backrouting "smoothes" the wood and prevents this from happening. Rabbets - I like to backrout when I need to cut a rabbet to hold a glass panel — the last thing I want to end up with is chipout So instead of routing in the normal direction, I backrout and make a very shallow, full-width cut (Figure 1). This lightly "scores" the edge of the rabbet. Once that's complete, you can make the rest of the cuts to the full depth of the rabbet routing in the proper direction (Figure 2). Ovals & Circles - I also like to backrout when I have to rout a profile on the edge of an oval or circle. Since there isn't a square corner, there isn't any specific end grain you can rout first. So I backrout instead. Here again, you'll want to take several very light cuts until you reach the full depth of the cut Then to remove any chatter marks, make a final pass with the router in the normal direction. Safety - So why not backrout all the time? The problem is the bit won't pull itself into the wood — it will bounce and skip along the edge, making the router difficult to control. To minimize this problem, I like to take light passes and keep a firm grip. Then I take a final ait in the proper direction to clean up the edge. MAKE SCORING PASS ON ALL WORK- PIECES ROUTING FROM RIGHT TO LEFT Safety Note: There's one very important thing to keep in mind here. Never backrout on a router table — the workpiece (and your fingers) can be pulled right into the router bit. No. 62 ShopNotes 33 |