69 - Bench Top Storage System, страница 14

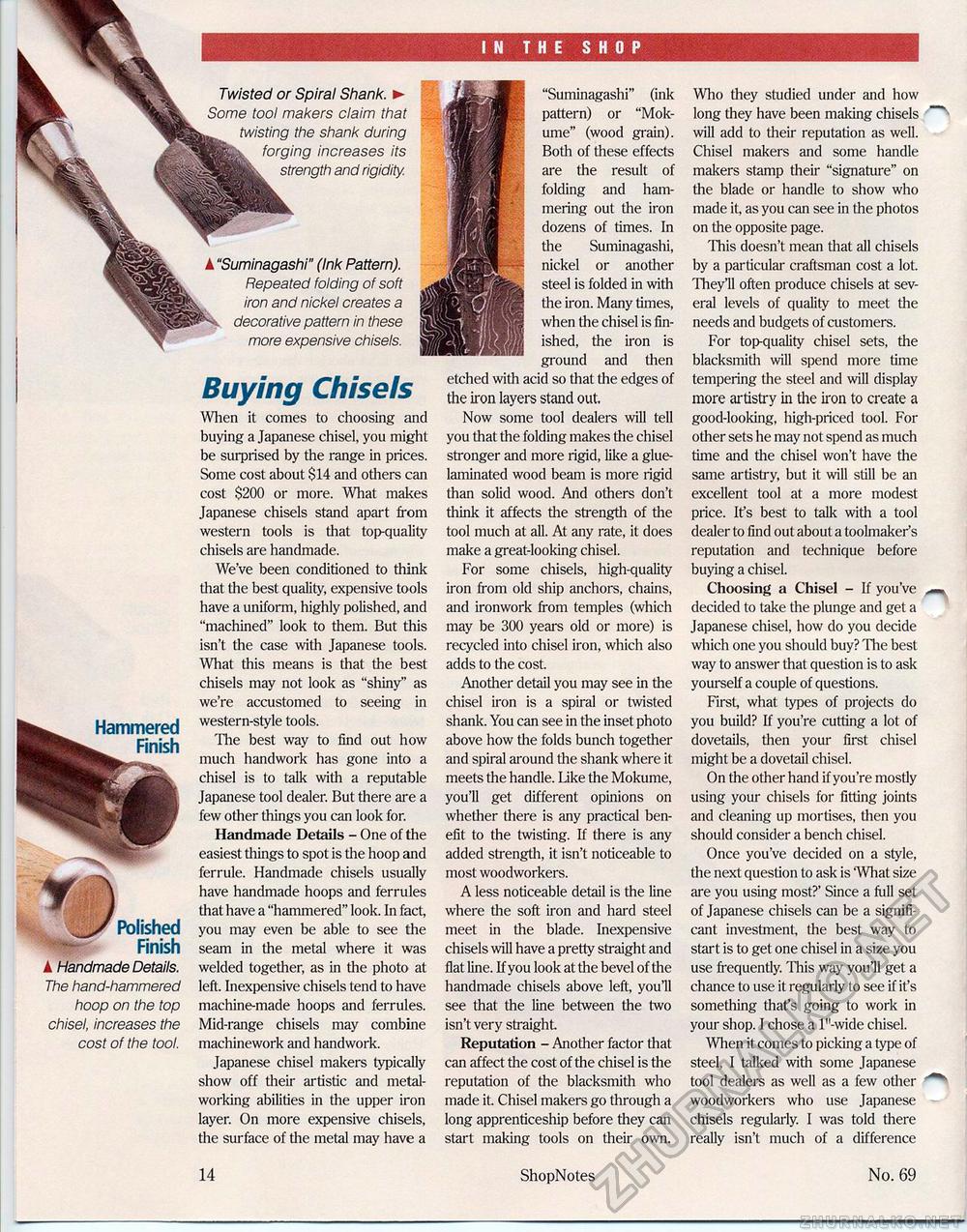

EHHIra ||gjgf|| Twisted or Spiral Shank. ► Some tool makers claim that twisting the shank during forging increases its strength and rigidity. ▲ "Suminagashi" (Ink Pattern). Repeated folding of soft iron and nickel creates a *< decorative pattern in these more expensive chisels. Buying ChiselsWhen it comes to choosing and buying a Japanese chisel, you might be surprised by the range in prices. Some cost about $14 and others can cost $200 or more. What makes Japanese chisels stand apart from western tools is that top-quality chisels are handmade. We've been conditioned to think that the best quality, expensive tools have a uniform, highly polished, and "machined" look to them. But this isn't the case with Japanese tools. What this means is that the best chisels may not look as "shiny" as we're accustomed to seeing in western-style tools. The best way to find out how much handwork has gone into a chisel is to talk with a reputable Japanese tool dealer. But there are a few other things you can look for. Handmade Details - One of the easiest things to spot is the hoop and ferrule. Handmade chisels usually have handmade hoops and ferrules that have a "hammered" look. In fact, you may even be able to see the seam in the metal where it was welded together, as in the photo at left. Inexpensive chisels tend to have machine-made hoops and ferrules. Mid-range chisels may combine machinework and handwork. Japanese chisel makers typically show off their artistic and metal-working abilities in the upper iron layer. On more expensive chisels, the surface of the metal may have a IN THE SHOP "Suminagashi" (ink pattern) or "Mok-ume" (wood grain). Both of these effects are the result of folding and hammering out the iron dozens of times. In the Suminagashi, nickel or another steel is folded in with the iron. Many times, when the chisel is finished, the iron is ground and then etched with acid so that the edges of the iron layers stand out. Now some tool dealers will tell you that the folding makes the chisel stronger and more rigid, like a glue-laminated wood beam is more rigid than solid wood. And others don't think it affects the strength of the tool much at all. At any rate, it does make a great-looking chisel. For some chisels, high-quality iron from old ship anchors, chains, and ironwork from temples (which may be 300 years old or more) is recycled into chisel iron, which also adds to the cost. Another detail you may see in the chisel iron is a spiral or twisted shank. You can see in the inset photo above how the folds bunch together and spiral around the shank where it meets the handle. Like the Mokume, you'll get different opinions on whether there is any practical benefit to the twisting. If there is any added strength, it isn't noticeable to most woodworkers. A less noticeable detail is the line where the soft iron and hard steel meet in the blade. Inexpensive chisels will have a pretty straight and flat line. If you look at the bevel of the handmade chisels above left, you'll see that the line between the two isn't very straight Reputation - Another factor that can affect the cost of the chisel is the reputation of the blacksmith who made it. Chisel makers go through a long apprenticeship before they can start making tools on their own. Who they studied under and how long they have been making chisels will add to their reputation as well. Chisel makers and some handle makers stamp their "signature" on the blade or handle to show who made it, as you can see in the photos on the opposite page. This doesn't mean that all chisels by a particular craftsman cost a lot. They'll often produce chisels at several levels of quality to meet the needs and budgets of customers. For top-quality chisel sets, the blacksmith will spend more time tempering the steel and will display more artistry in the iron to create a good-looking, high-priced tool. For other sets he may not spend as much time and the chisel won't have the same artistry, but it will still be an excellent tool at a more modest price. Ifs best to talk with a tool dealer to find out about a toolmaker's reputation and technique before buying a chisel. Choosing a Chisel - If you've decided to take the plunge and get a Japanese chisel, how do you decide which one you should buy? 'Hie best way to answer that question is to ask yourself a couple of questions. First, what types of projects do you build? If you're cutting a lot of dovetails, then your first chisel might be a dovetail chisel. On the other hand if you're mostly using your chisels for fitting joints and cleaning up mortises, then you should consider a bench chisel. Once you've decided on a style, the next question to ask is 'What size are you using most?' Since a full set of Japanese chisels can be a significant investment, the best way to start is to get one chisel in a size you use frequently. This way you'll get a chance to use it regularly to see if it's something that's going to work in your shop. I chose a l"-wide chisel. When it comes to picking a type of steel, I talked with some Japanese tool dealers as well as a few other woodworkers who use Japanese chisels regularly. I was told there really isn't much of a difference Polished Finish A Handmade Details. The hand-hammered hoop on the top chisel, increases the cost of the tool. Hammered Finish 14 ShopNotes No. 69 |