69 - Bench Top Storage System, страница 25

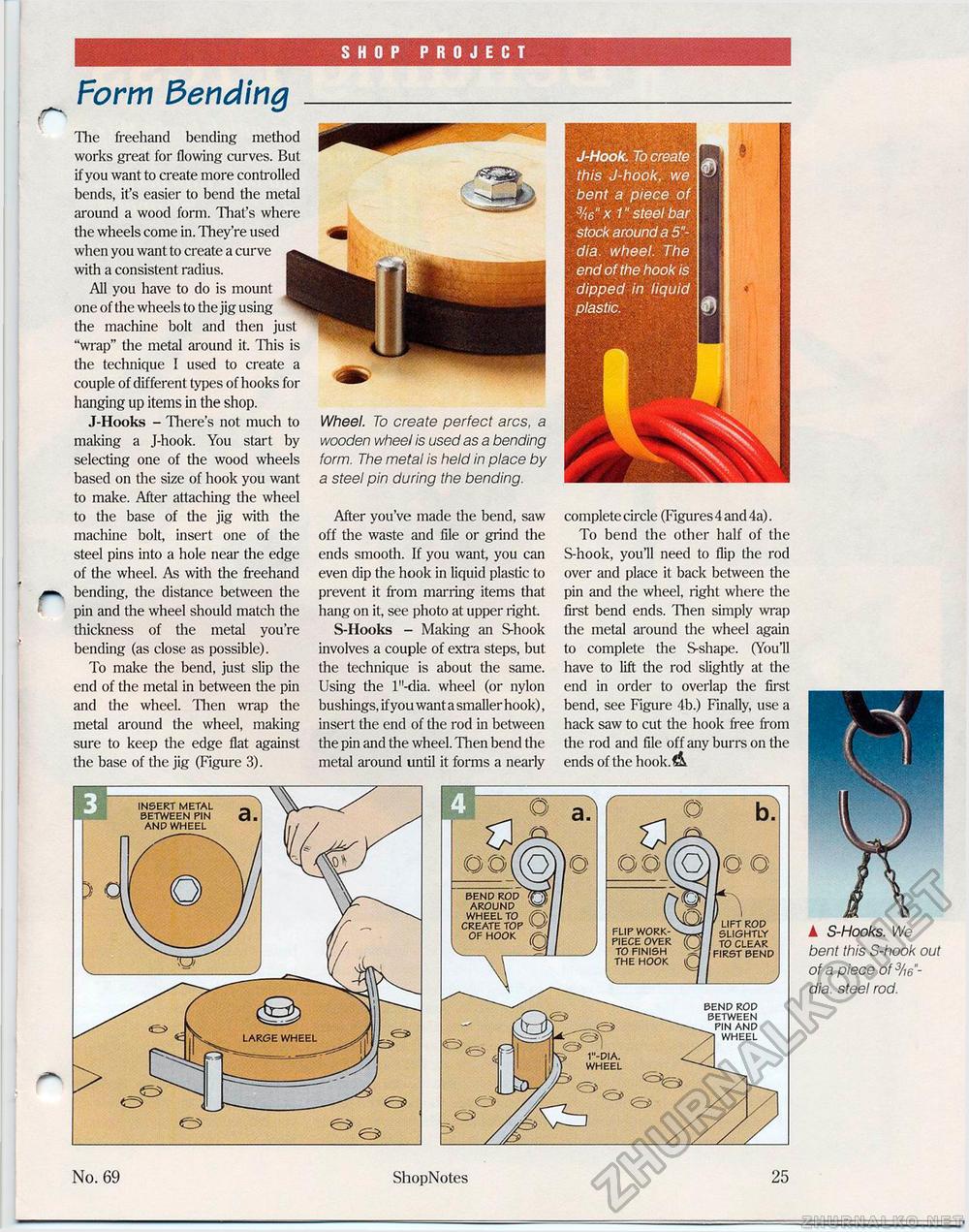

SHOP PROJECT r Form deriding'Hie freehand bending method works great for flowing curves. But if you want to create more controlled bends, it's easier to bend the metal around a wood form. That's where the wheels come in. They're used when you want to create a curve with a consistent radius. All you have to do is mount one of the wheels to the jig using the machine bolt and then just "wrap" the metal around it. This is the technique I used to create a couple of different types of hooks for hanging up items in the shop. J-Hooks - There's not much to making a J-hook. You start by selecting one of the wood wheels based on the size of hook you want to make. After attaching the wheel to the base of the jig with the machine bolt, insert one of the steel pins into a hole near the edge of the wheel. As with the freehand bending, the distance between the pin and the wheel should match the thickness of the metal you're bending (as close as possible). To make the bend, just slip the end of the metal in between the pin and the wheel. Then wrap the metal around the wheel, making sure to keep the edge flat against the base of the jig (Figure 3). Wheel. To create perfect arcs, a wooden wheel is used as a bending form. The metal is held in place by a steel pin during the bending. After you've made the bend, saw off the waste and file or grind the ends smooth. If you want, you can even dip the hook in liquid plasdc to prevent it from marring items that hang on it, see photo at upper right. S-Hooks - Making an S-hook involves a couple of extra steps, but the technique is about the same. Using the l"-dia. wheel (or nylon bushings, if you want a smaller hook), insert the end of the rod in between the pin and the wheel. Then bend the metal around until it forms a nearly complete circle (Figures 4 and 4a). To bend the other half of the S-hook, you'll need to flip the rod over and place it back between the pin and the wheel, right where the first bend ends. Then simply wrap the metal around the wheel again to complete the S-shape. (You'll have to lift the rod slightiy at the end in order to overlap the first bend, see Figure 4b.) Finally, use a hack saw to cut the hook free from the rod and file off any burrs on the ends of the hook.& ▲ S-Hooks. We bent this S-hook out of a piece of 3/w"~ dia. steel rod. J-Hook. To create this J-hook, we bent a piece of 3/i6" x 1" steel bar stock around a 5"-dia. wheel. The end of the hook is dipped in liquid INSERT METAL BETWEEN PIN AND WHEEL No. 69 ShopNotes 25 |