69 - Bench Top Storage System, страница 28

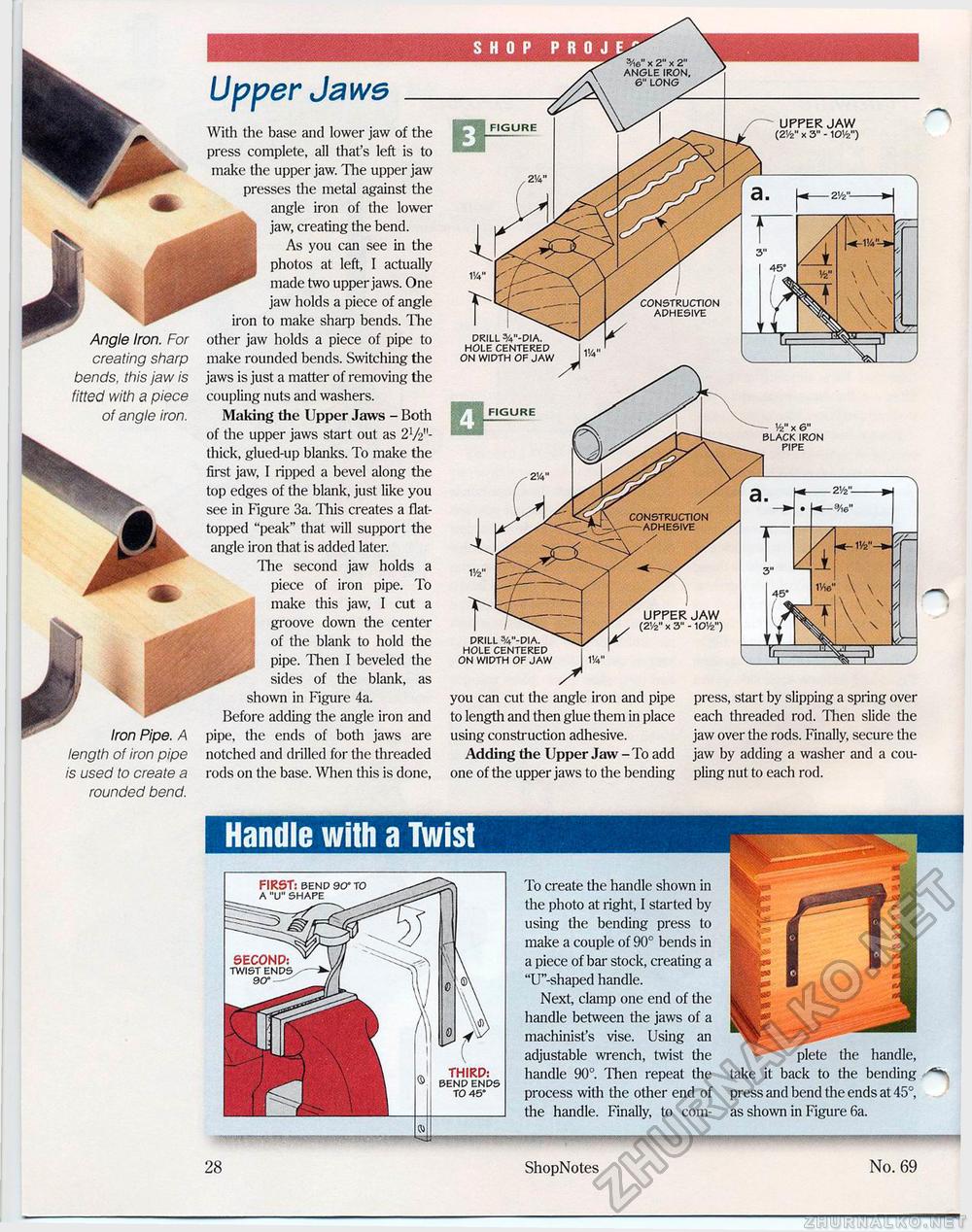

Upper J awe Angle Iron. For creating sharp bends, this jaw is fitted with a piece of angle iron. Iron Pipe. A length of iron pipe is used to create a rounded bend. With the base and lower jaw of the press complete, all that's left is to make the upper jaw. The upper jaw presses the metal against the angle iron of the lower |g, jaw, creating the bend. As you can see in the photos at left, I actually made two upper jaws. One jaw holds a piece of angle iron to make sharp bends. 'Hie other jaw holds a piece of pipe to make rounded bends. Switching the jaws is just a matter of removing the coupling nuts and washers. Making the Upper Jaws - Both of the upper jaws start out as 21/2n-thick, glued-up blanks. To make the first jaw, I ripped a bevel along the top edges of the blank, just like you see in Figure 3a. 'Ibis creates a flat-topped "peak" that will support the angle iron that is added later. The second jaw holds a piece of iron pipe. To make this jaw, I cut a groove down the center of the blank to hold the pipe. Then I beveled the sides of the blank, as shown in Figure 4a. Before adding the angle iron and pipe, the ends of both jaws are notched and drilled for the threaded rods on the base. When this is done. PRILL 3/V'-DIA. HOLE CENTEREP ON WIPTH OF JAW you can cut the angle iron and pipe press, start by slipping a spring over to length and then glue them in place each threaded rod. Then slide die using construction adhesive. jaw over the rods. Finally, secure the Adding the Upper Jaw - To add jaw by adding a washer and a cou- one of the upper jaws to the bending pling nut to each rod. SECOND: TWIST ENPS 90° THIRD: BENPENPS TO 45° To create the handle shown in the photo at right, I started by using the bending press to make a couple of 90° bends in a piece of bar stock, creating a "U"-shaped handle. Next, clamp one end of the handle between the jaws of a machinist's vise. Using an adjustable wrench, twist the handle 90°. Then repeat the process with the other end of the handle. Finally, to com plete the handle, take it back to the bending press and bend the ends at 45°, as shown in Figure 6a. 28 ShopNotes No. 69 |