69 - Bench Top Storage System, страница 29

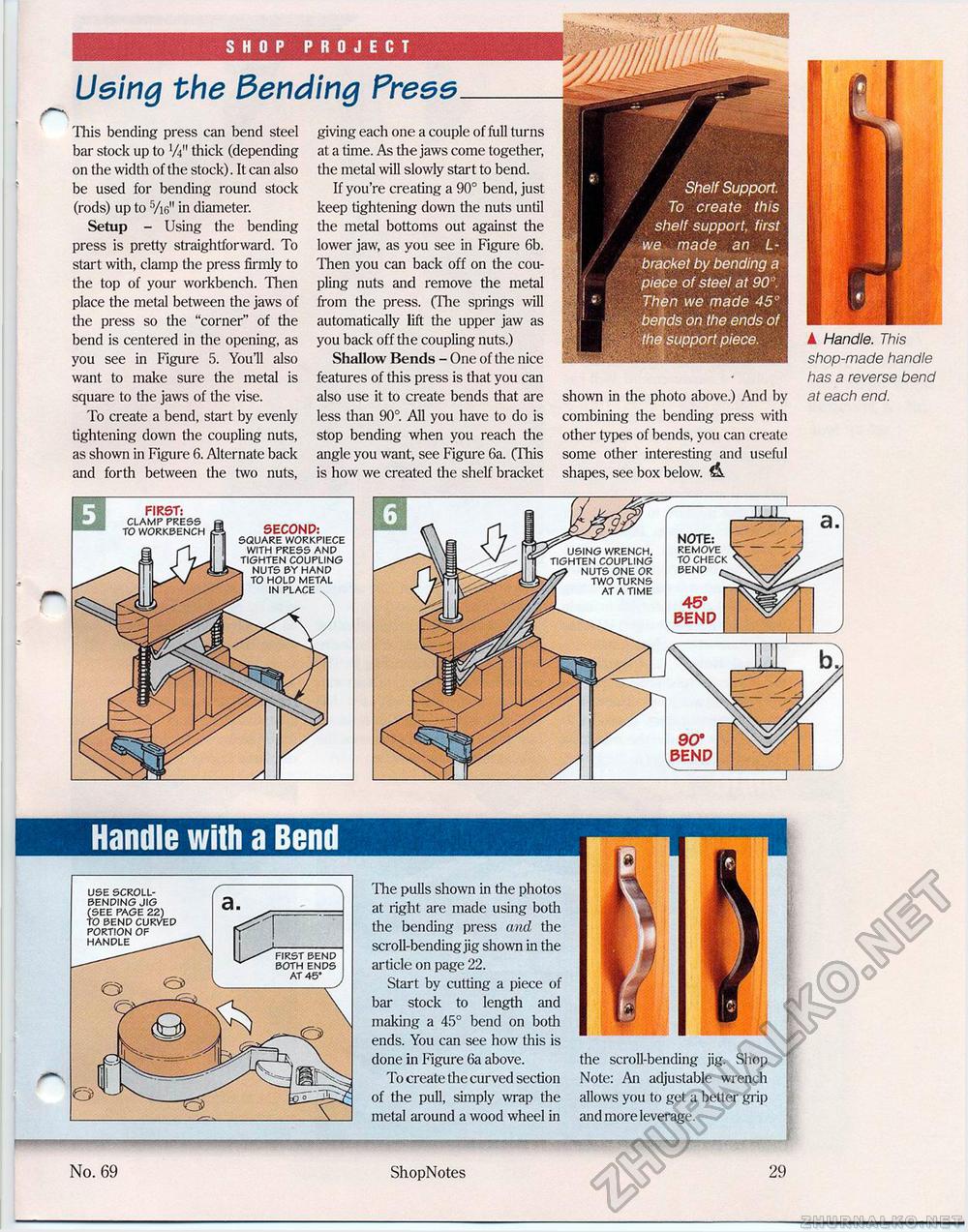

Handle with a Bend The pulls shown in the photos at right are made using both the bending press and the scroll-bending jig shown in the article on page 22. Start by cutting a piece of bar stock to length and making a 45° bend on both ends. You can see how this is done in Figure 6a above. To create the curved section of the pull, simply wrap the metal around a wood wheel in the scroll-bending jig. Shop Note: An adjustable wrench allows you to get a better grip and more leverage. No. 69 ShopNotes 29 Shelf Support. M To create this shelf support, first we made an L-bracket by bending a piece of steel at 90 Then we made 45° bends on the ends of the support piece. Ueing the dending Frees This bending press can bend steel bar stock up to Vi" thick (depending on the width of the stock). It can also be used for bending round stock (rods) up to Vie" in diameter. Setup - Using the bending press is pretty straightforward. To start with, clamp the press firmly to the top of your workbench. Then place the metal between the jaws of the press so the "corner" of the bend is centered in the opening, as you see in Figure 5. You'll also want to make sure the metal is square to the jaws of the vise. To create a bend, start by evenly tightening down the coupling nuts, as shown in Figure 6. Alternate back and forth between the two nuts, giving each one a couple of full turns at a time. As the jaws come together, the metal will slowly start to bend. If you're creating a 90° bend, just keep tightening down the nuts until the metal bottoms out against the lower jaw, as you see in Figure 6b. Then you can back off on the coupling nuts and remove the metal from the press. (The springs will automatically lift the upper jaw as you back off the coupling nuts.) Shallow Bends - One of the nice features of this press is that you can also use it to create bends that are less than 90°. All you have to do is stop bending when you reach the angle you want, see Figure 6a. (This is how we created the shelf bracket shown in the photo above.) And by combining the bending press with other types of bends, you can create some other interesting and useful shapes, see box below. A Handle. This shop-made handle has a reverse bend at each end. FIRST: CLAMP PRESS TO WORKBENCH SECOND: SQUARE WORKPIECE WITH PRESS AND TIGHTEN COUPLING NUTS BY HAND TO HOLD METAL 90' BEND USING WRENCH. TIGHTEN COUPLING NUTS ONE OR TWO TURNS AT A TIME NOTE: REMOVE TO CHECK BEND ^ 45° BEND FIRST BEND BOTH ENDS AT 45' |