81 - Ultimate Sharpening Station, страница 13

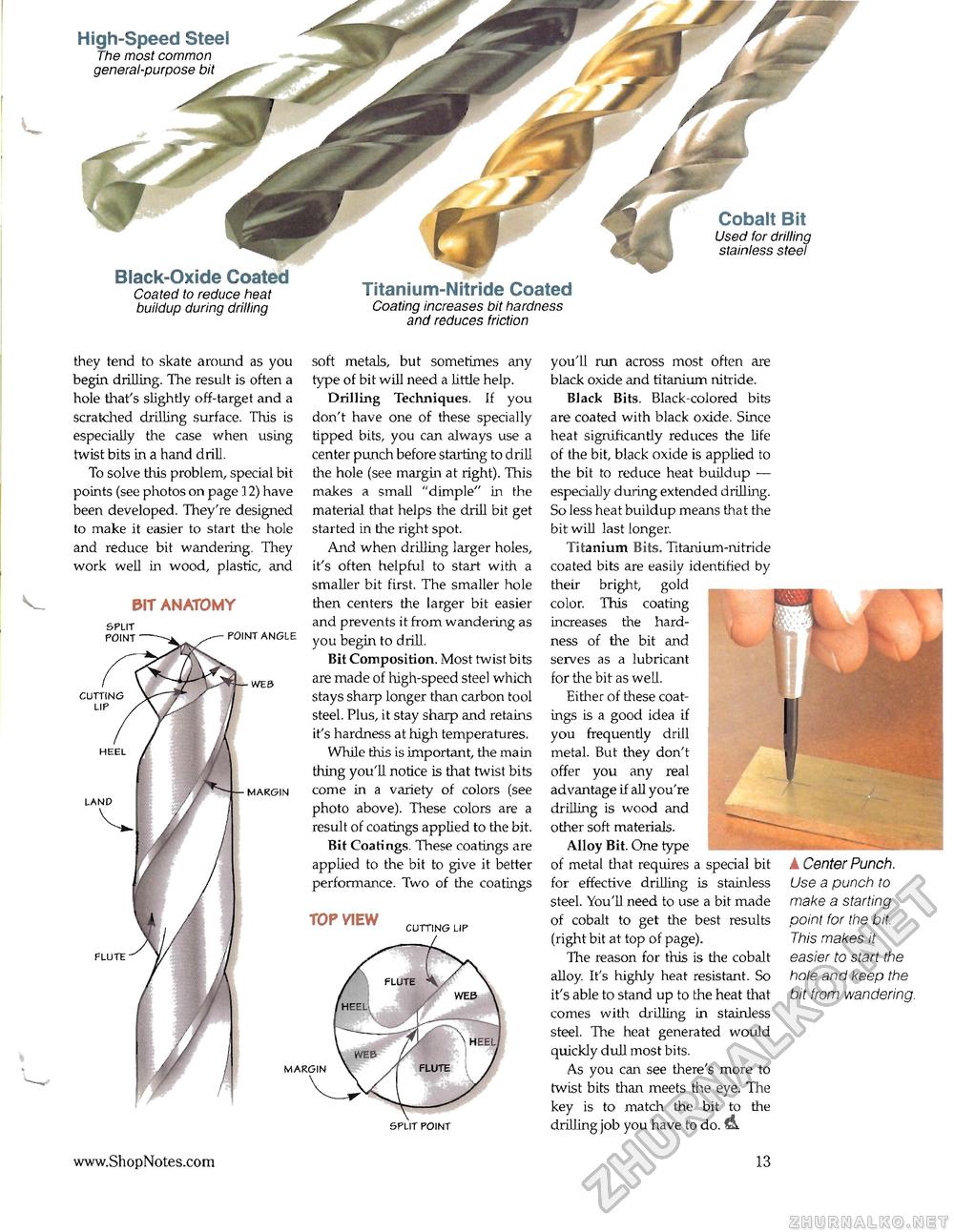

Cobalt Bit Used for drilling stainless steel High-Speed Steel The most common general-purpose bit Black-Oxide Coated Coated to reduce heat buildup during drilling Titanium-Nitride Coated Coating increases bit hardness and reduces friction you'll run across most often are black oxide and titanium nitride. Black Bits. Black-colored bits are coated with black oxide. Since heat significantly reduces the life of the bit, black oxide is applied to the bit to reduce heat buildup — especially during extended drilling. So less heat buildup means that the bit will last longer. Titanium Bits. Titanium-nitride coated bits are easily identified by their bright, gold color. This coating increases the hardness of the bit and serves as a lubricant for the bit as well. Either of these coatings is a good idea if you frequently drill metal. But they don't offer you any real advantage if all you're drilling is wood and other soft materials. Alloy Bit. One type ▲ Center Punch. Use a punch to make a starting point for the bit. This makes it easier to start the hole and keep the bit from wandering. of metal that requires a special bit for effective drilling is stainless steel. You'll need to use a bit made of cobalt to get the best results (right bit at top of page). The reason for this is the cobalt alloy. It's highly heat resistant. So it's able to stand up to the heat that comes with drilling in stainless steel. The heat generated would quickly dull most bits. As you can see there's more to twist bits than meets the eye. The key is to match the bit to the drilling job you have to do. & soft metals, but sometimes any type of bit will need a little help. Drilling Techniques. If you don't have one of these specially tipped bits, you can always use a center punch before starting to drill the hole (see margin at right). This makes a small "dimple" in the material that helps the drill bit get started in the right spot. And when drilling larger holes, it's often helpful to start with a smaller bit first. The smaller hole then centers the larger bit easier and prevents it from wandering as you begin to drill. Bit Composition. Most twist bits are made of high-speed steel which stays sharp longer than carbon tool steel. Plus, it stay sharp and retains it's hardness at high temperatures. While this is important, the main thing you'll notice is that twist bits come in a variety of colors (see photo above). These colors are a result of coatings applied to the bit. Bit Coatings. These coatings are applied to the bit to give it better performance. Two of the coatings top view cuttinglip MARGIN SPLIT POINT FLUTE they tend to skate around as you begin drilling. The result is often a hole that's slightly off-target and a scratched drilling surface. This is especially the case when using twist bits in a hand drill. To solve this problem, special bit points (see photos on page 12) have been developed. They're designed to make it easier to start the hole and reduce bit wandering. They work well in wood, plastic, and bit anatomy SPLIT POINT---^—POINT ANGLE HEEL CUTTING LIP WEB LAND MARGIN 13 |