81 - Ultimate Sharpening Station, страница 11

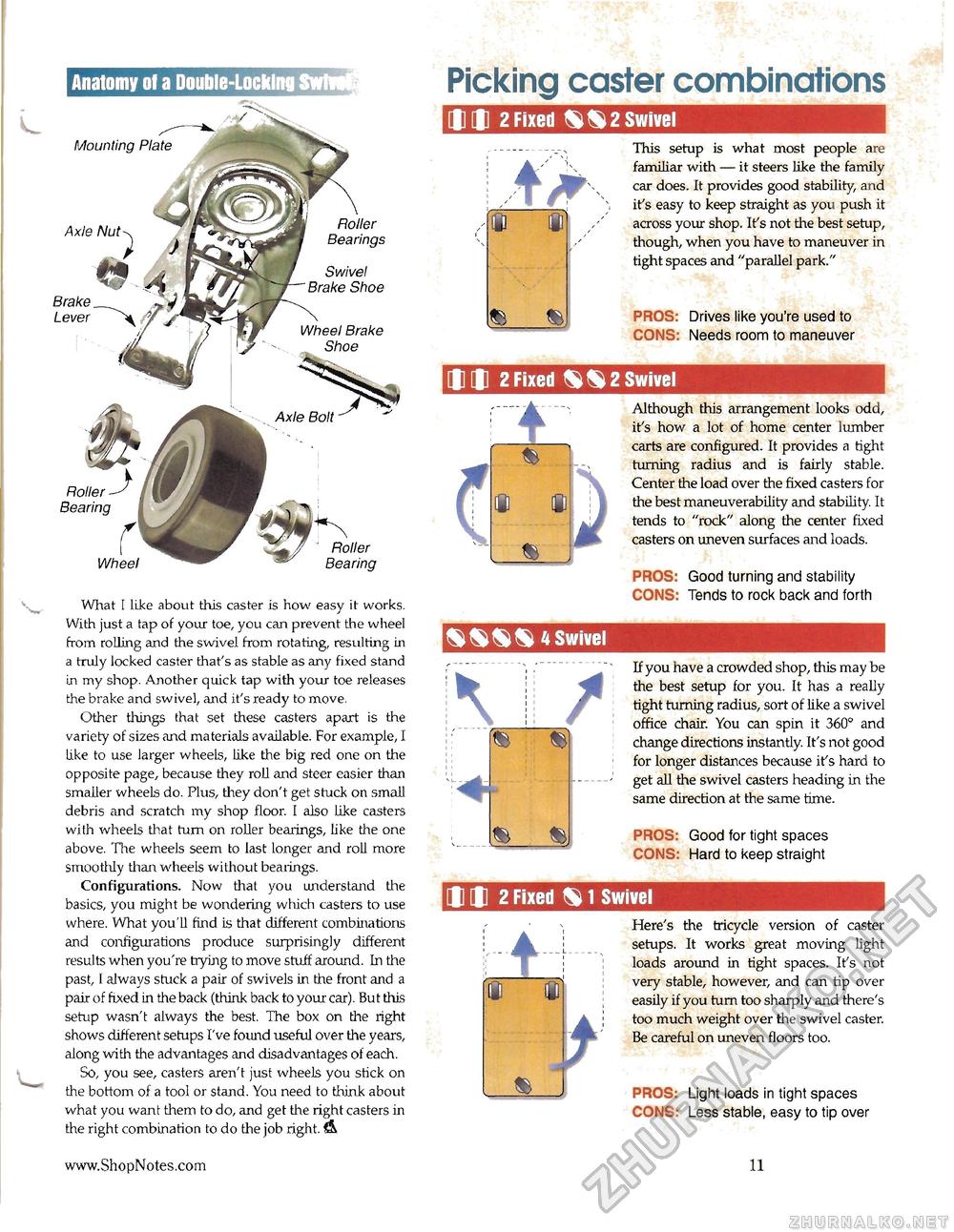

Anatomy of a Double-Locking Picking caster combinations l® 2 Fixed %% 2 Swivel

This setup is what most people are familiar with — it steers like the family car does. It provides good stability, and it's easy to keep straight as you push it across your shop. It's not the best setup, though, when you have to maneuver in tight spaces and "parallel park." PROS: Drives like you're used to CONS: Needs room to maneuver Hd 2 Fixed SS2 Swivel What I like about this caster is how easy it works. With just a tap of your toe, you can prevent the wheel from rolling and the swivel from rotating, resulting in a truly locked caster that's as stable as any fixed stand in my shop. Another quick tap with your toe releases the brake and swivel, and it's ready to move. Other things that set these casters apart is the variety of sizes and materials available. For example, I like to use larger wheels, like the big red one on the opposite page, because they roll and steer easier than smaller wheels do. Plus, they don't get stuck on small debris and scratch my shop floor. I also like casters with wheels that turn on roller bearings, like the one above. The wheels seem to last longer and roll more smoothly than wheels without bearings. Configurations. Now that you understand the basics, you might be wondering which casters to use where. What you'll find is that different combinations and configurations produce surprisingly different results when you're trying to move stuff around. In the past, I always stuck a pair of swivels in the front and a pair of fixed in the back (think back to your car). But this setup wasn't always the best. The box on the right shows different setups I've found useful over the years, along with the advantages and disadvantages of each. So, you see, casters aren't just wheels you stick on the bottom of a tool or stand. You need to think about what you want them to do, and get the right casters in the right combination to do the job right. & ♦ r

$$$$ 4 Swivel

Although this arrangement looks odd, it's how a lot of home center lumber carts are configured. It provides a tight turning radius and is fairly stable. Center the load over the fixed casters for the best maneuverability and stability. It tends to "rock" along the center fixed casters on uneven surfaces and loads. PROS: Good turning and stability CONS: Tends to rock back and forth If you have a crowded shop, this may be the best setup for you. It has a really tight turning radius, sort of like a swivel office chair. You can spin it 360° and change directions instantly. It's not good for longer distances because if s hard to get all the swivel casters heading in the same direction at the same time. PROS: Good for tight spaces CONS: Hard to keep straight [J® 2 Fixed $ 1 Swivel Here's the tricycle version of caster setups. It works great moving light loads around in tight spaces. It's not very stable, however, and can tip over easily if you turn too sharply and there's too much weight over the swivel caster. Be careful on uneven floors too. PROS: Light loads in tight spaces CONS: Less stable, easy to tip over Roller Bearing Mounting Plate Roller Bearing Wheel Roller Bearings Swivel Brake Shoe Wheel Brake Shoe 11 |