81 - Ultimate Sharpening Station, страница 12

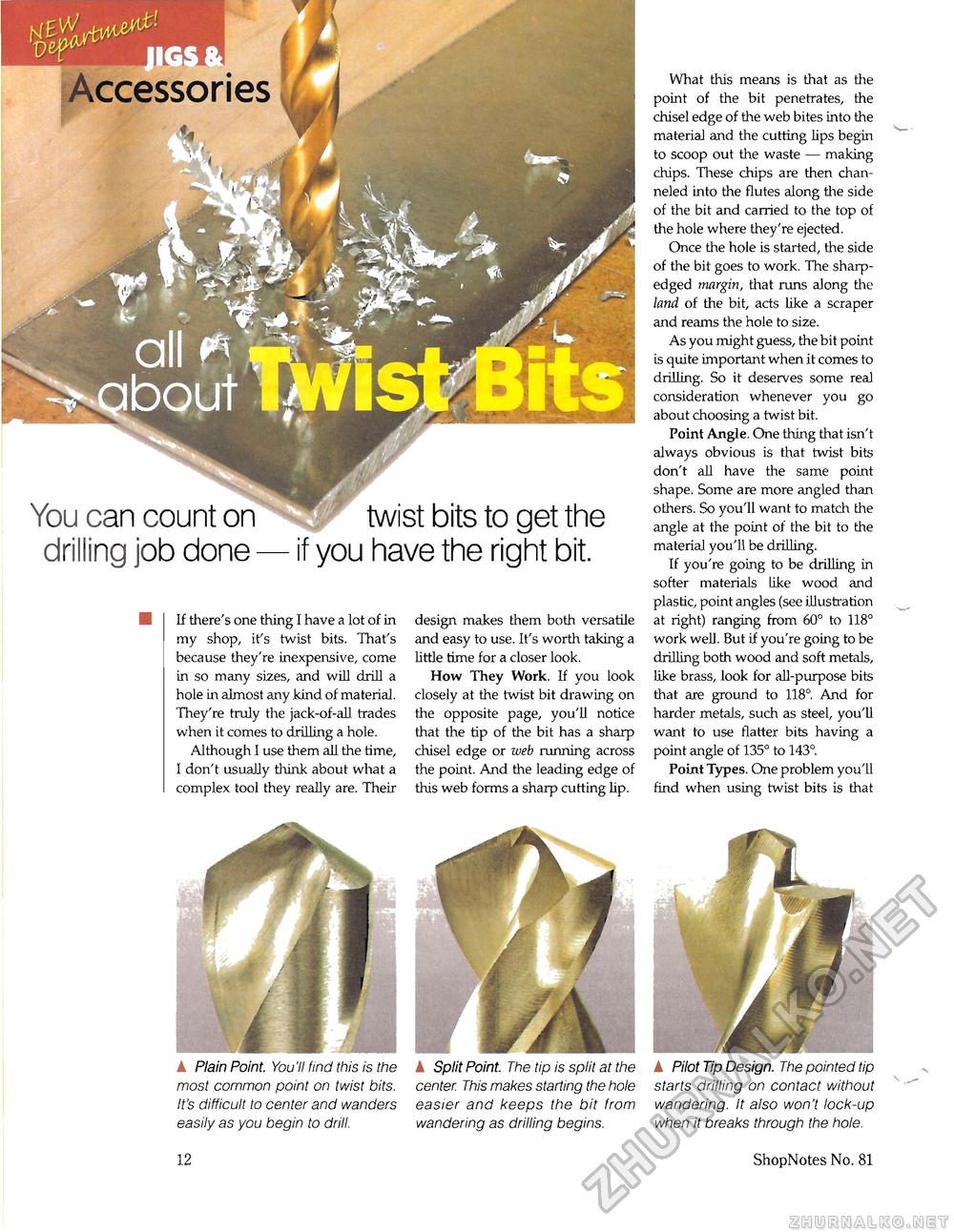

You can count on drilling job done twist bits to get the if you have the right bit. What this means is that as the point of the bit penetrates, the chisel edge of the web bites into the materia] and the cutting lips begin to scoop out the waste — making chips. These chips are then channeled into the flutes along the side of the bit and carried to the top of the hole where they're ejected. Once the hole is started, the side of the bit goes to work. The sharp-edged margin, that runs along the land of the bit, acts like a scraper and reams the hole to size. As you might guess, the bit point is quite important when it comes to drilling. So it deserves some real consideration whenever you go about choosing a twist bit. Point Angle. One thing that isn't always obvious is that twist bits don't all have the same point shape. Some are more angled than others. So you'll want to match the angle at the point of the bit to the material you'll be drilling. If you're going to be drilling in softer materials like wood and plastic, point angles (see illustration at right) ranging from 60° to 118° work well. But if you're going to be drilling both wood and soft metals, like brass, look for all-purpose bits that are ground to 118°. And for harder metals, such as steel, you'll want to use flatter bits having a point angle of 135° to 143°. Point Types. One problem you'll find when using twist bits is that A Pilot Tip Design. The pointed tip starts drilling on contact without wandering. It also won't lock-up when it breaks through the hole. If there's one thing I have a lot of in my shop, ifs twist bits. That's because they're inexpensive, come in so many sizes, and will drill a hole in almost any kind of material. They're truly the jack-of-all trades when it comes to drilling a hole. Although I use them all the time, I don't usually think about what a complex tool they really are. Their A Plain Point. You'll find this is the most common point on twist bits. It's difficult to center and wanders easily as you begin to drill. A Split Point. The tip is split at the center. This makes starting the hole easier and keeps the bit from wandering as drilling begins. design makes them both versatile and easy to use. It's worth taking a little time for a closer look. How They Work. If you look closely at the twist bit drawing on the opposite page, you'll notice that the tip of the bit has a sharp chisel edge or web running across the point. And the leading edge of this web forms a sharp cutting lip. 12 ShopNotes No. 81 |