83, страница 45

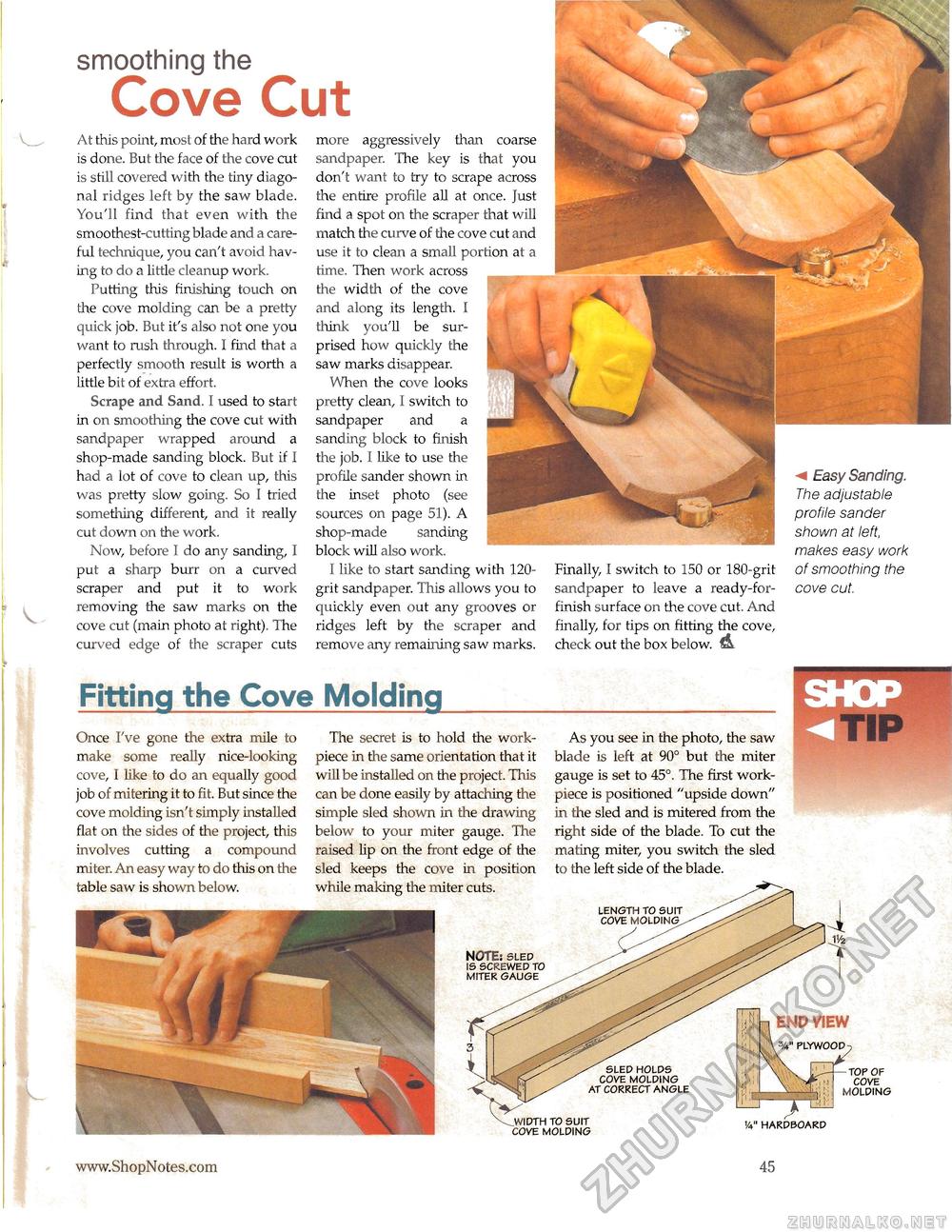

smoothing the Cove Cut At this point, most of the hard work is done. But the face of the cove cut is still covered with the tiny diagonal ridges left by the saw blade. You'll find that even with the smoothest-cutting blade and a careful technique, you can't avoid having to do a little cleanup work. Putting this finishing touch on the cove molding can be a pretty quick job. But it's also not one you want to rush through. I find that a perfectly smooth result is worth a little bit of extra effort. Scrape and Sand. I used to start in on smoothing the cove cut with sandpaper wrapped around a shop-made sanding block. But if I had a lot of cove to clean up, this was pretty slow going. So I tried something different, and it really cut down on the work. Now, before I do any sanding, I put a sharp burr on a curved scraper and put it to work removing the saw marks on the cove cut (main photo at right). The curved edge of the scraper cuts more aggressively than coarse sandpaper. The key is that you don't want to try to scrape across the entire profile all at once. Just find a spot on the scraper that will match the curve of the cove cut and use it to clean a small portion at a time. Then work across the width of the cove and along its length. I think you'll be surprised how quickly the saw marks disappear. When the cove looks pretty clean, I switch to sandpaper and a sanding block to finish the job. I like to use the profile sander shown in the inset photo (see sources on page 51). A shop-made sanding block will also work. I like to start sanding with 120-grit sandpaper. This allows you to quickly even out any grooves or ridges left by the scraper and remove any remaining saw marks. Finally, I switch to 150 or 180-grit sandpaper to leave a ready-for-finish surface on the cove cut. And finally, for tips on fitting the cove, check out the box below. & M Easy Sanding. The adjustable profile sander shown at left, makes easy work of smoothing the cove cut. END VIEW Fitting the Cove Molding top of cove molding NOTE: sled is screwed to miter gauge sled holds cove molding at correct angle to suit molding Once I've gone the extra mile to make some really nice-looking cove, I like to do an equally good job of mitering it to fit. But since the cove molding isn't simply installed flat on the sides of the project, this involves cutting a compound miter. An easy way to do this on the table saw is shown below. The secret is to hold the work-piece in the same orientation that it will be installed on the project. This can be done easily by attaching the simple sled shown in the drawing below to your miter gauge. The raised lip on the front edge of the sled keeps the cove in position while making the miter cuts. As you see in the photo, the saw blade is left at 90° but the miter gauge is set to 45°. The first work-piece is positioned "upside down" in the sled and is mitered from the right side of the blade. To cut the mating miter, you switch the sled to the left side of the blade. length cove |