83, страница 42

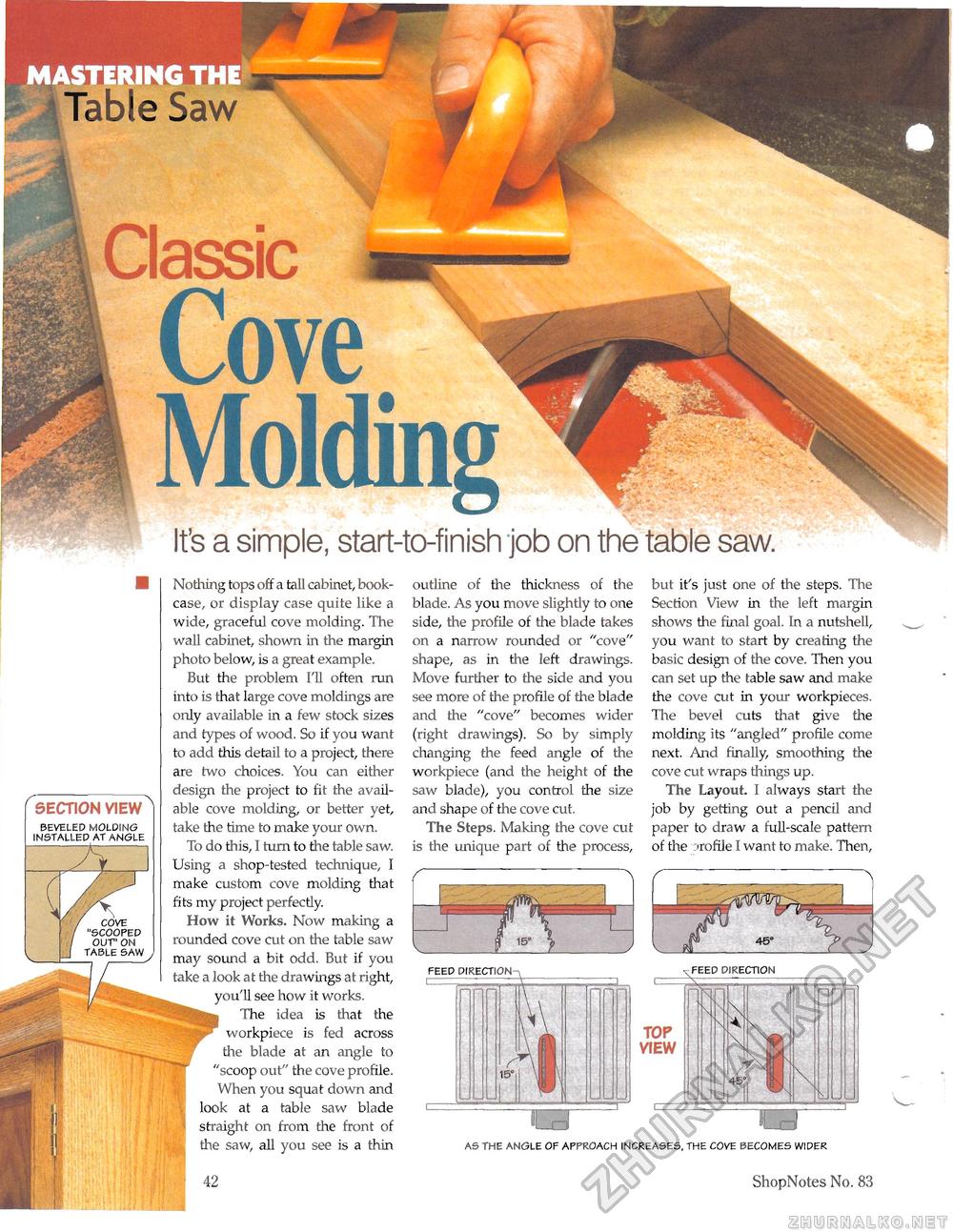

MASTERING THE Table Saw Classic Molding It's a simple, start-to-finish job on the table saw. SECTION VIEW BEVELED MOLDING INSTALLED AT ANGLE Nothing tops off a tall cabinet, bookcase, or display case quite like a wide, graceful cove molding. The wall cabinet, shown in the margin photo below, is a great example. But the problem I'll often run into is that large cove moldings are only available in a few stock sizes and types of wood. So if you want to add this detail to a project, there are two choices. You can either design the project to fit the available cove molding, or better yet, take the time to make your own. To do this, I turn to the table saw. Using a shop-tested technique, I make custom cove molding that fits my project perfectly. How it Works. Now making a rounded cove cut on the table saw may sound a bit odd. But if you take a look at the drawings at right, you'll see how it works. The idea is that the workpiece is fed across the blade at an angle to "scoop out" the cove profile. When you squat down and look at a table saw blade straight on from the front of the saw, all you see is a thin 42 outline of the thickness of the blade. As you move slightly to one side, the profile of the blade takes on a narrow rounded or "cove" shape, as in the left drawings. Move further to the side and you see more of the profile of the blade and the "cove" becomes wider (right drawings). So by simply changing the feed angle of the workpiece (and the height of the saw blade), you control the size and shape of the cove cut. The Steps. Making the cove cut is the unique part of the process, but it's just one of the steps. The Section View in the left margin shows the final goal. In a nutshell, you want to start by creating the basic design of the cove. Then you can set up the table saw and make the cove CLit in your workpieces. The bevel cuts that give the molding its "angled" profile come next. And finally, smoothing the cove cut wraps things up. The Layout. I always start the job by getting out a pencil and paper to draw a full-scale pattern of the to file I want to make. Then, AS THE ANGLE OF APPROACH INCREASES, THE COVE BECOMES WIDER ShopNotes No. 83 |