83, страница 39

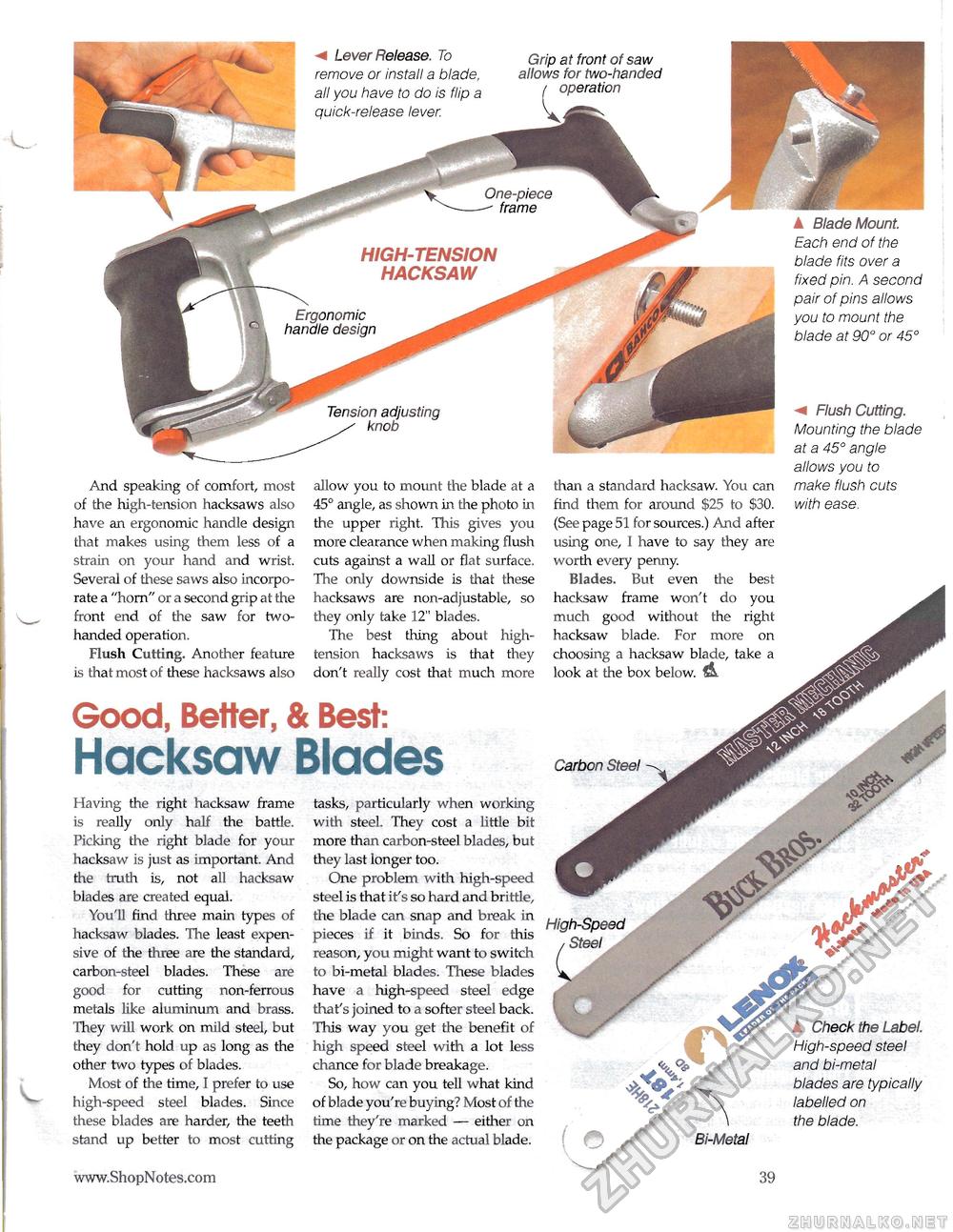

Lever Release. To remove or install a blade, all you have to do is flip a quick-release lever. Grip at front of saw allows for two-handed / operation One-piece - frame k Blade Mount. Each end of the blade fits over a fixed pin. A second pair of pins allows you to mount the blade at 90° or 45° HIGH-TENSION HACKSAW Ergonomic handle design ■< Flush Cutting. Mounting the blade at a 45° angle allows you to make flush cuts with ease. Tension adjusting / knob And speaking of comfort, most of the high-tension hacksaws also have an ergonomic handle design that makes using them less of a strain on your hand and wrist. Several of these saws also incorporate a "horn" or a second grip at the front end of the saw for two-handed operation. Flush Cutting. Another feature is that most of these hacksaws also allow you to mount the blade at a 45° angle, as shown in the photo in the upper right. This gives you more clearance when making flush cuts against a wall or flat surface. The only downside is that these hacksaws are non-adjustable, so they only take 12" blades. The best thing about high-tension hacksaws is that they don't really cost that much more than a standard hacksaw. You can find them for around $2.5 to $30. (See page 51 for sources.) And after using one, I have to say they are worth every penny. Blades. But even the best hacksaw frame won't do you much good without the right hacksaw blade. For more on choosing a hacksaw blade, take a look at the box below. Carbon Steel k Check the Label. High-speed steel and bi-metai blades are typically labelled on the blade. L. Good, Better, & Best: Hacksaw Blades Having the right hacksaw frame is really only half the battle. Picking the right blade for your hacksaw is just as important. And the truth is, not all hacksaw blades are created equal. You'll find three main types of hacksaw blades. The least expensive of the three are the standard, carbon-steel blades. These are good for cutting non-ferrous metals like aluminum and brass. They will work on mild steel, but they don't hold up as long as the other two types of blades. Most of the time, I prefer to use high-speed steel blades. Since these blades are harder, the teeth stand up better to most cutting tasks, particularly when working with steel. They cost a little bit more than carbon-steel blades, but they last longer too. One problem with high-speed steel is that it's so hard and brittle, the blade can snap and break in pieces if it binds. So for this reason, you might want to switch to bi-metal blades. These blades have a high-speed steel edge that's joined to a softer steel back. This way you get the benefit of high speed steel with a lot less chance for blade breakage. So, how can you tell what kind of blade you're buying? Most of the time they're marked — either on the package or on the actual blade. |