83, страница 38

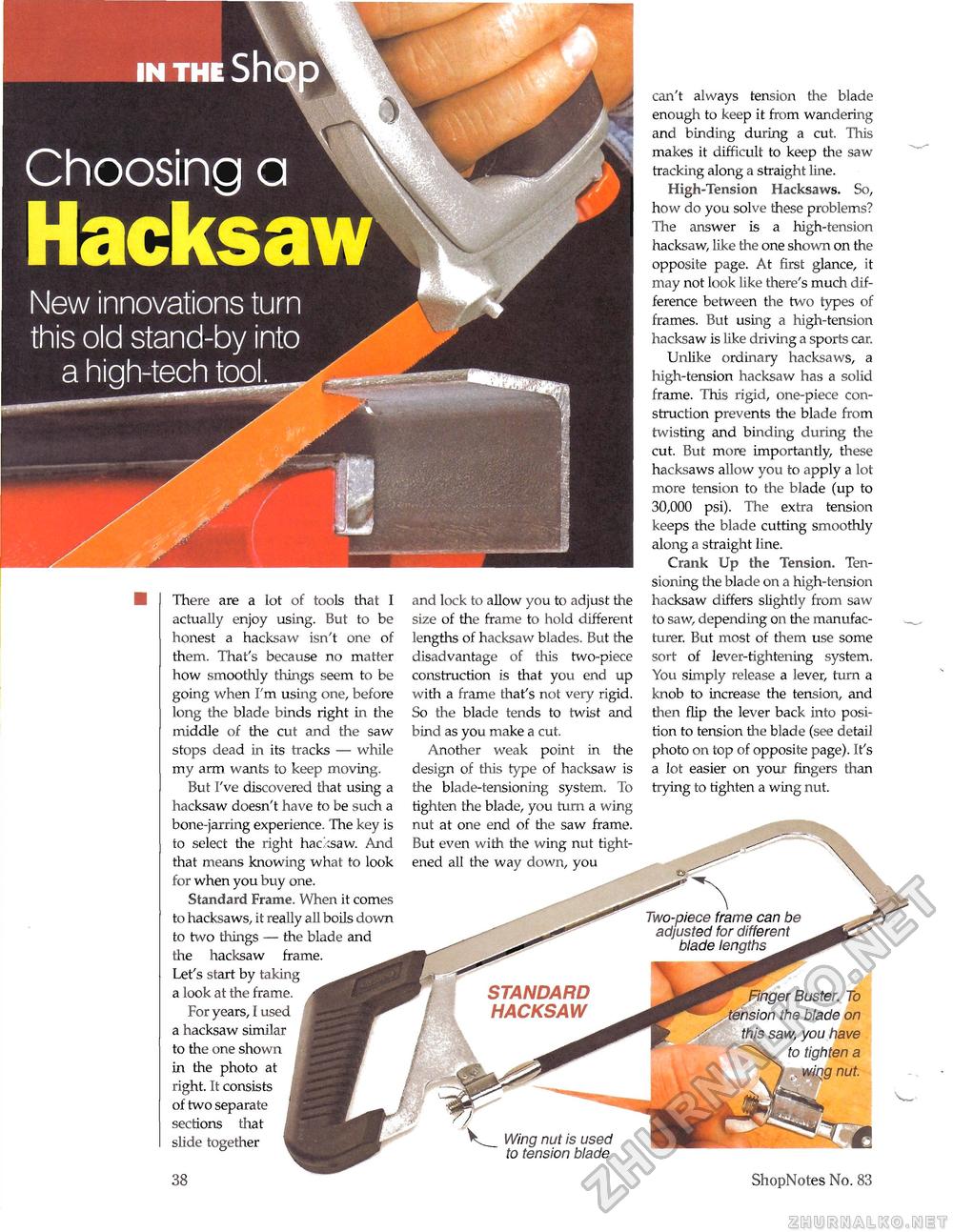

IN THE Shftp New innovations turn this old stand-by into a high-tech tool, / wr m rJ There are a lot of tools that I actually enjoy using. But to be honest a hacksaw isn't one of them. That's because no matter how smoothly things seem to be going when I'm using one, before long the blade binds right in the middle of the cut and the saw stops dead in its tracks — while my arm wants to keep moving. But I've discovered that using a hacksaw doesn't have to be such a bone-jarring experience. The key is to select the right hacksaw. And that means knowing what to look for when you buy one. Standard Frame. When it comes to hacksaws, it really all boils down to two things — the blade and the hacksaw frame. Let's start by taking a look at the frame. For years, I used a hacksaw similar to the one shown in the photo at right. It consists of two separate ■gj^^g _ .' sections that slide together 38 and lock to allow you to adjust the size of the frame to hold different lengths of hacksaw blades. But the disadvantage of this two-piece construction is that you end up with a frame that's not very rigid. So the blade tends to twist and bind as you make a cut. Another weak point in the design of this type of hacksaw is the blade-tensioning system. To tighten the blade, you turn a wing nut at one end of the saw frame. But even with the wing nut tightened all the way down, you can't always tension the blade enough to keep it from wandering and binding during a cut. This makes it difficult to keep the saw tracking along a straight line. High-Tension Hacksaws. So, how do you solve these problems? The answer is a high-tension hacksaw, like the one shown on the opposite page. At first glance, it may not look like there's much difference between the two types of frames. But using a high-tension hacksaw is like driving a sports car. Unlike ordinary hacksaws, a high-tension hacksaw has a solid frame. This rigid, one-piece construction prevents the blade from twisting and binding during the cut. But more importantly, these hacksaws allow you to apply a lot more tension to the blade (up to 30,000 psi). The extra tension keeps the blade cutting smoothly along a straight line. Crank Up the Tension. Tensioning the blade on a high-tension hacksaw differs slightly from saw to saw, depending on the manufacturer. But most of them use some sort of lever-tightening system. You simply release a lever, turn a knob to increase the tension, and then flip the lever back into position to tension the blade (see detail photo on top of opposite page). It's a lot easier on your fingers than trying to tighten a wing nut. Finger Buster. To tension the blade on this saw, you have to tighten a „ wing nut. Wing nut is used to tension blade 38 ShopNotes No. 83 |