83, страница 40

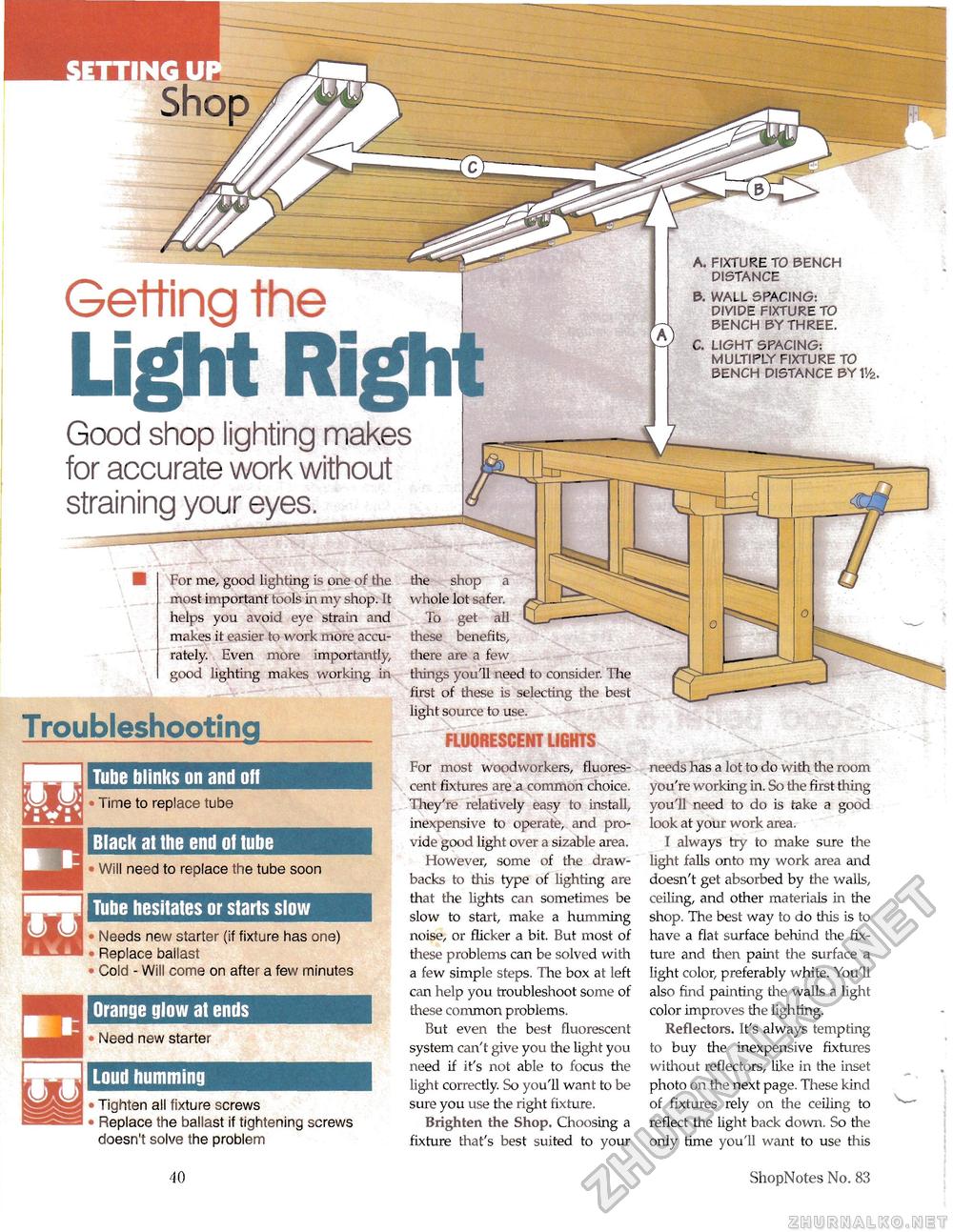

Tube blinks on and off Time to replace tube Black at the end of tube Will need to replace the tube soon Tube hesitates or starts slow Needs new starter (if fixture has one) Replace ballast Cold - Will come on after a few minutes Orange glow at ends Need new starter Loud humming Tighten all fixture screws Replace the ballast if tightening screws doesn't solve the problem Getting the T Light Right Good shop lighting makes for accurate work without straining your eyes. these benefits, there are a few tilings you'll need to consider, first of these is selecting the best light source to use. FLUORESCENT LIGHTS For most woodworkers, fluorescent fixtures are a common choice. They're relatively easy to install, inexpensive to operate, and provide good light over a sizable area. However, some of the drawbacks to this type of lighting are that the lights can sometimes be slow to start, make a humming noise, or flicker a bit. But most of these problems can be solved with a few simple steps. The box at left can help you troubleshoot some of these common problems. But even the best fluorescent system can't give you the light you need if it's not able to focus the light correctly. So you'll want to be sure you use the right fixture. Brighten the Shop. Choosing a fixture that's best suited to your Troubleshooting needs has a lot to do with the room you're working in. So the first thing you'll need to do is take a good look at your work area. I always try to make sure the light falls onto my work area and doesn't get absorbed by the walls, ceiling, and other materials in the shop. The best way to do this is to have a flat surface behind the fixture and then paint the surface a light color, preferably white. You'll also find painting the walls a light color improves the lighting. Reflectors. It's always tempting to buy the inexpensive fixtures without reflectors, like in the inset photo on the next page. These kind of fixtures rely on the ceiling to reflect the light back down. So the only time you'll want to use this 3. WALL SPACING: DIVIDE FIXTURE TO BENCH BY THREE. C. LIGHT SPACING: MULTIPLY FIXTURE TO BENCH DISTANCE BY 1V2. A. FIXTURE TO BENCH DISTANCE For makes it easier to work more accurately. Even more importantly, good lighting makes working in 40 ShopNotes No. 83 |