83, страница 37

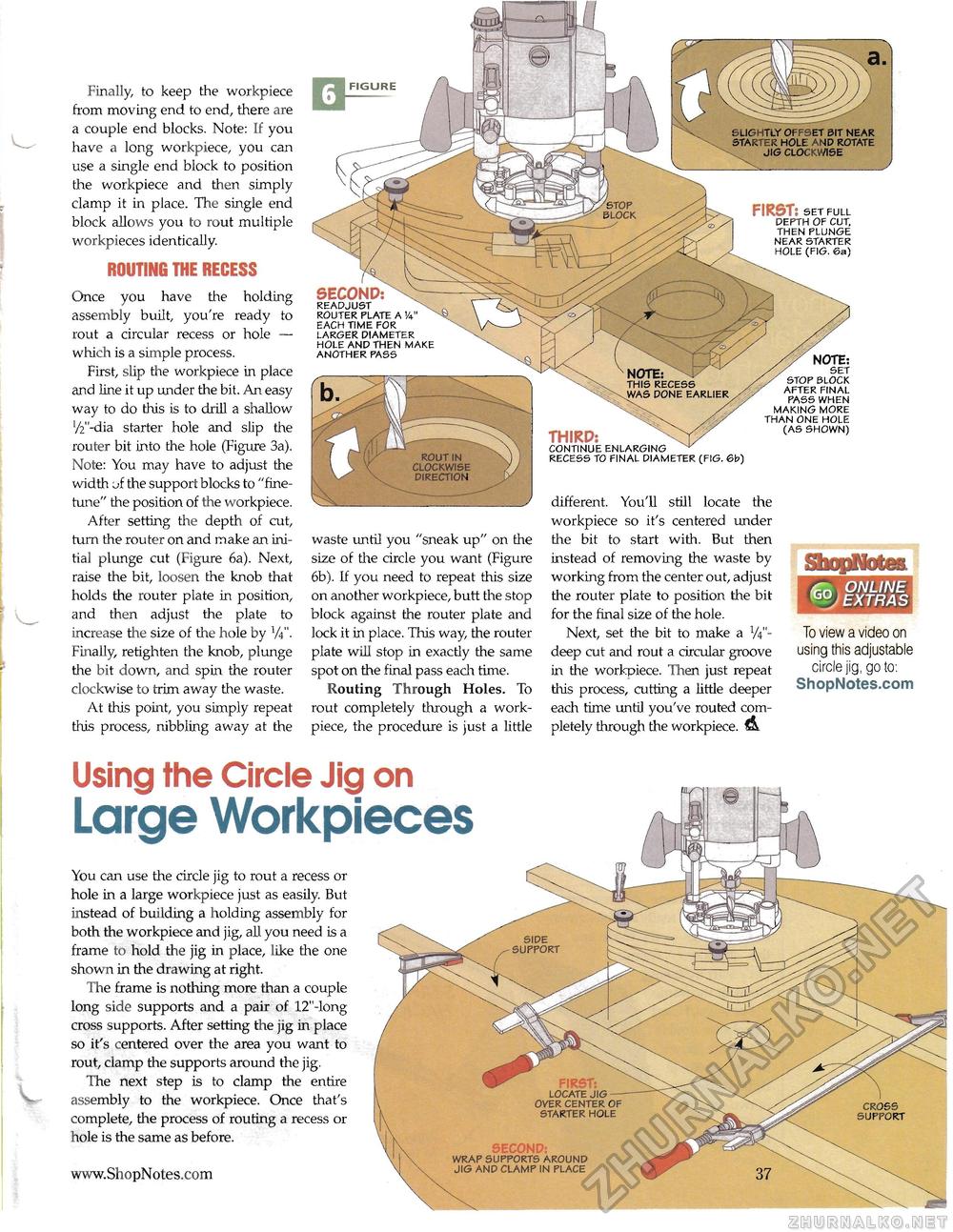

Finally, to keep the workpiece from moving end to end, there are a couple end blocks. Note: If you have a long workpiece, you can use a single end block to position the workpiece and then simply clamp it in place. The single end block allows you to rout multiple workpieces identically. ROUTING THE RECESS Once you have the holding assembly built, you're ready to rout a circular recess or hole — which is a simple process. First, slip the workpiece in place and line it up under the bit. An easy way to do this is to drill a shallow '/2"-dia starter hole and slip the router bit into the hole (Figure 3a). Note: You may have to adjust the width uf the support blocks to "fine-tune" the position of the workpiece. After setting the depth of cut, turn the router on and make an initial plunge cut (Figure 6a). Next, raise the bit, loosen the knob that holds the router plate in position, and then adjust the plate to increase the size of the hole by Vi". Finally, retighten the knob, plunge the bit down, and spin the router clockwise to trim away the waste. At this point, you simply repeat this process, nibbling away at the ShopMotea fn ONLINE G0j EXTRAS FIGURE slightly offset bit near starter hole and rotate jig clockwise FIRST; SET FULL DEPTH OF CUT. THEN PLUNGE NEAR STARTER HOLE (FIG. 6a) THIRD: CONTINUE ENLARGING RECESS TO FINAL DIAMETER (FIG. 6b) NOTE: SET STOP BLOCK AFTER FINAL PASS WHEN MAKING MORE THAN ONE HOLE (AS SHOWN) different. You'll still locate the workpiece so it's centered under the bit to start with. But then instead of removing the waste by working from the center out, adjust the router plate to position the bit for the final size of the hole. Next, set the bit to make a XW~ deep cut and rout a circular groove in the workpiece. Then just repeat this process, cutting a little deeper each time until you've routed completely through the workpiece. A. To view a video on using this adjustable circle jig, go to: ShopNotes.com SECOND: READJUST ROUTER PLATE A 'A" EACH TIME FOR LARGER DIAMETER HOLE AND THEN MAKE ANOTHER PASS waste until you "sneak up" on the size of the circle you want (Figure 6b). If you need to repeat this size on another workpiece, butt the stop block against the router plate and lock it in place. This way, the router plate will stop in exactly the same spot on the final pass each time. Routing Through Holes. To rout completely through a work-piece, the procedure is just a little SIDE SUPPORT FIRST: LOCATE JIG — OVER CENTER OF STARTER HOLE SECOND: WRAP SUPPORTS AROUND JIG AND CLAMP IN PLACE CROSS SUPPORT Using the Circle Jig on Large WorkpiecesYou can use the circle jig to rout a recess or hole in a large workpiece just as easily. But instead of building a holding assembly for both the workpiece and jig, all you need is a frame to hold the jig in place, like the one shown in the drawing at right. The frame is nothing more than a couple long side supports and a pair of 12"-long cross supports. After setting the jig in place so it's centered over the area you want to rout, clamp the supports around the jig. The next step is to clamp the entire assembly to the workpiece. Once that's complete, the process of routing a recess or hole is the same as before. |