84, страница 24

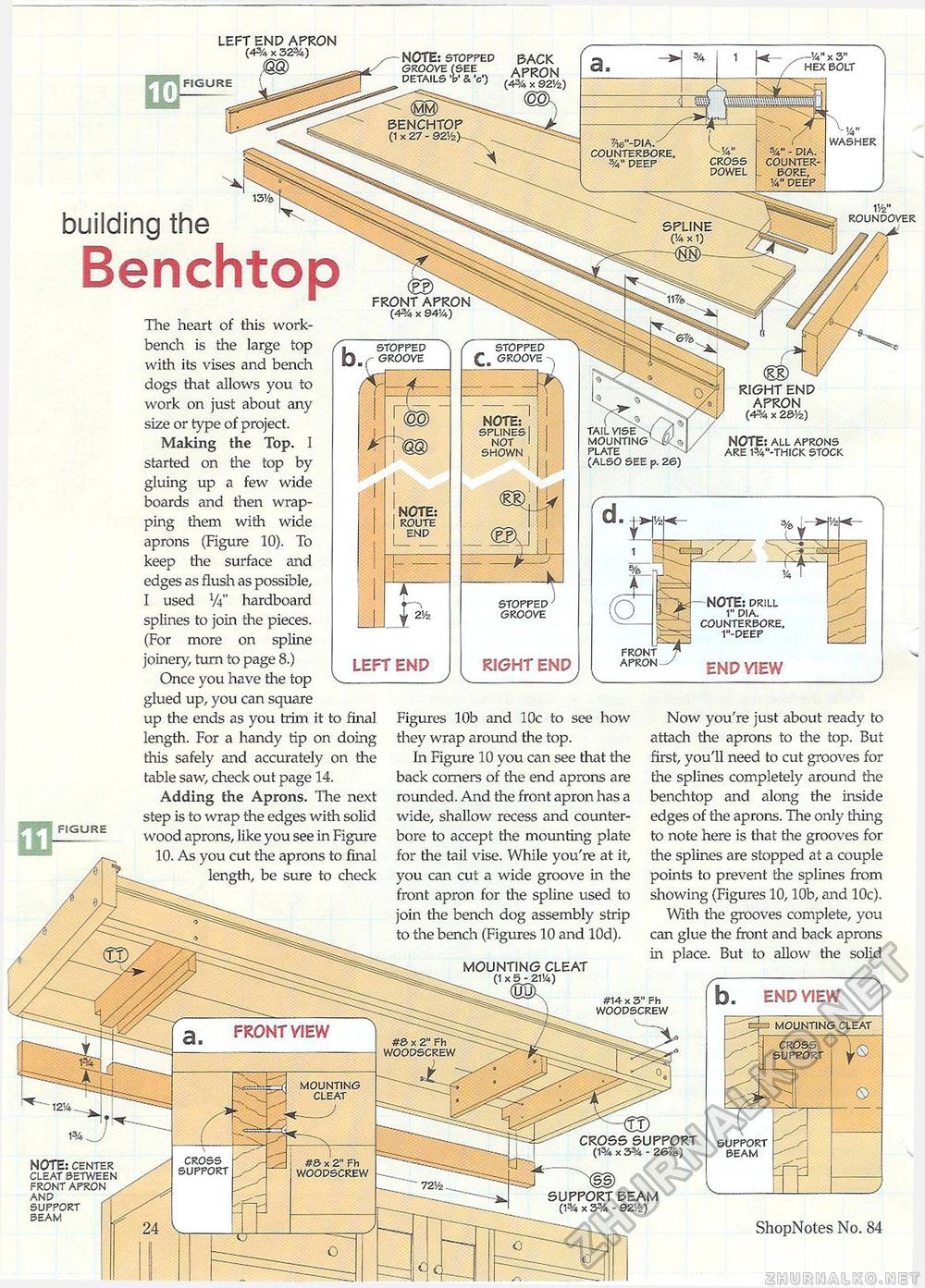

left end apron (4% x 32%) note: stopped GROOVE (SEE DETAILS 'b' & 'c') -y4"x3" HEX BOLT back apron (4% x 92V2) m. benchtop (1 x 27 - 92'/z>- WASHER ?16"-DIA. COUNTERBORE, %"DEEP CROSS DOWEL %" - dia. COUNTER- BORE, va" deep IV2" ROUNDOVER building the Benchtop spline ('/* X 1) ---<ss>- front apron (4% x 94'/4) The heart of this workbench is the large top i with its vises and bench dogs that allows you to f% work on just about any size or type of project. Making the Top. I £ started on the top by gluing up a few wide boards and then wrapping them with wide aprons (Figure 10). To keep the surface and edges as flush as possible, I used V4" hardboard splines to join the pieces. |_| (For more on spline joiner}', turn to page 8.) ^gp Once you have the top v _ glued up, you can square up the ends as you trim it to final length. For a handy tip on doing this safely and accurately on the table saw, check out page 14. Adding the Aprons. The next step is to wrap the edges with solid wood aprons, like you see in Figure 10. As you cut the aprons to final length, be sure to check <m right end apron (4% x 2&y2) TAIL VISE V A MOUNTING K o, PLATE (ALSO SEE p. 2S) note: SPLINES NOT SHOWN note: ALL APRONS ARE W-THICK STOCK note: ROUTE END note: drill 1" dia. counterbore, 1"-deep STOPPED GROOVE FRONT / APRON - -s RIGHT END Figures 10b and 10c to see how they wrap around the top. In Figure 10 you can see that the back corners of the end aprons are rounded. And the front apron has a wide, shallow recess and counter-bore to accept the mounting plate for the tail vise. While you're at it, you can cut a wide groove in the front apron for the spline used to join the bench dog assembly strip to the bench (Figures 10 and lOd). Now you're just about ready to attach the aprons to the top. But first, you'll need to cut grooves for the splines completely around the benchtop and along the inside edges of the aprons. The only thing to note here is that the grooves for the splines are stopped at a couple points to prevent the splines from showing (Figures 10,10b, and 10c). With the grooves complete, you can glue the front and back aprons in place. But to allow the solid mounting cleat (1x5- 2114) #14 x 3" Fh WOODSCREW MOUNTING CLEAT FRONT VIEW #£> x 2" Fh WOODSCREW CROSS SUPPORT MOUNTING CLEAT cross support (1% X 3% - 26%) SUPPORT BEAM CROSS SUPPORT #S x 2" Fh WOODSCREW NOTE: CENTER CLEAT BETWEEN FRONT APRON AND S SUPPORT BEAM , XgS) support beam (1% x 3% - 92V2) ShopNotes No. 84 |