84, страница 6

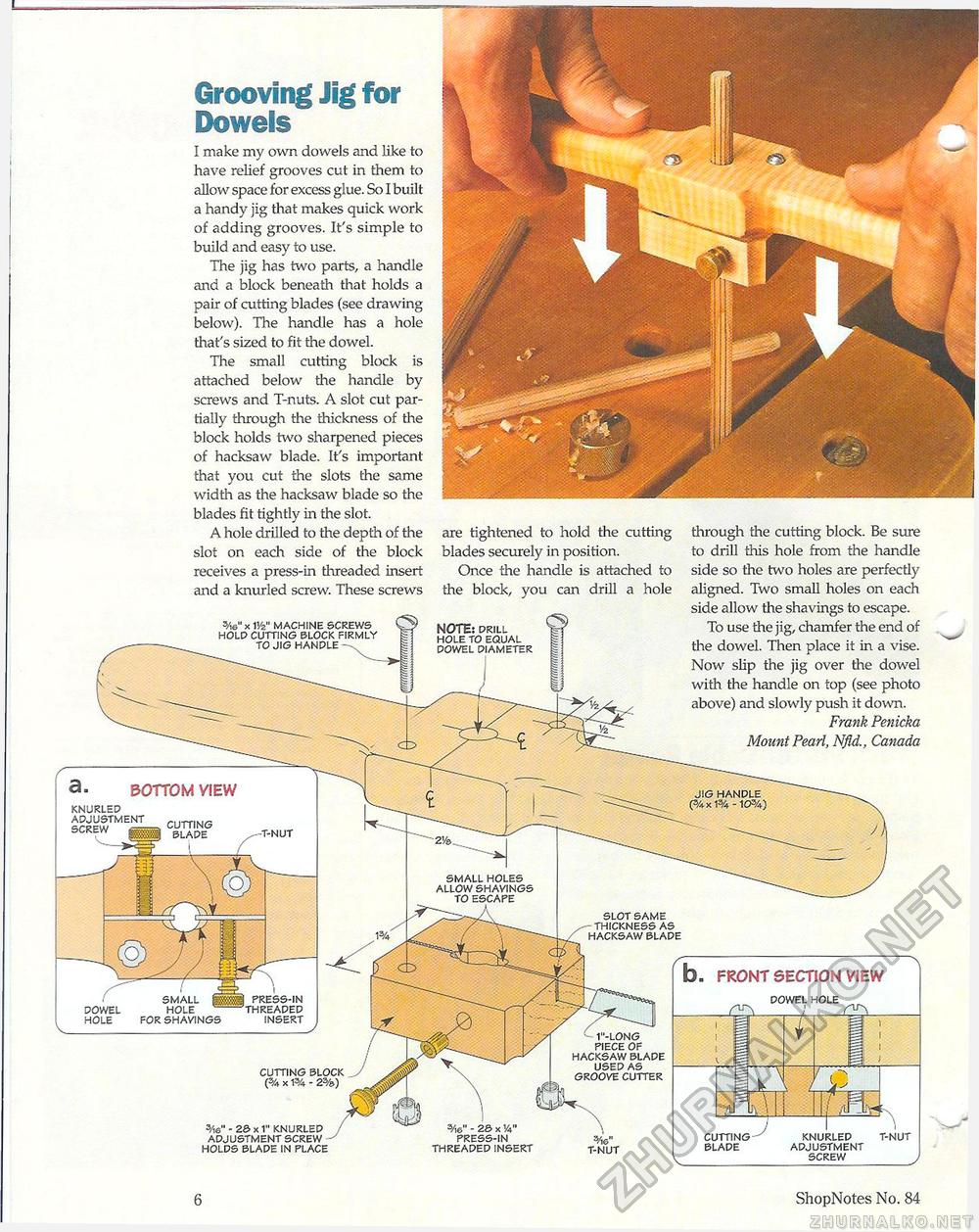

Grooving Jig for Dowels NOTE: drill HOLE TO EQUAL DOWEL DIAMETER JIG HANDLE (%x 1% -10%) CUTTING BLADE b. FRONT SECTION VIEW DOWEL HOLE BOTTOM VIEW KNURLED ADJUSTMENT SCREW -T-NUT DOWEL HOLE SMALL HOLE FOR SHAVINGS I PRESS-IN 'THREADED INSERT CUTTING BLOCK (% x 1% - 2%) Me" - 2S x 1" KNURLED ADJUSTMENT SCREW HOLDS BLADE IN PLACE 1"-L0NG PIECE OF HACKSAW BLADE USED AS GROOVE CUTTER 6" - 28 x V PRESS-IN THREADED INSERT CUTTING BLADE KNURLED T-NUT ADJUSTMENT SCREW are tightened to hold the cutting blades securely in position. Once the handle is attached to the block, you can drill a hole through the cutting block. Be sure to drill this hole from the handle side so the two holes are perfectly aligned. Two small holes on each side allow the shavings to escape. To use the jig, chamfer the end of the dowel. Then place it in a vise. Now slip the jig over the dowel with the handle on top (see photo above) and slowly push it down. Frank Penicka Mount Pearl, Nftd., Canada I make my own dowels and like to have relief grooves cut in them to allow space for excess glue. So I built a handy jig that makes quick work of adding grooves. It's simple to build and easy to use. The jig has two parts, a handle and a block beneath that holds a pair of cutting blades (see drawing below). The handle has a hole that's sized to fit the dowel. The small cutting block is attached below the handle by screws and T-nuts. A slot cut partially through the thickness of the block holds two sharpened pieces of hacksaw blade. It's important that you cut the slots the same width as the hacksaw blade so the blades fit tightly in the slot. A hole drilled to the depth of the slot on each side of the block receives a press-in threaded insert and a knurled screw. These screws SMALL HOLES ALLOW SHAVINGS TO ESCAPE I A SLOT SAME - THICKNESS AS HACKSAW BLADE 3Ae" x V/z" MACHINE SCREWS HOLD CUTTING BLOCK FIRMLY TO JIG HANDLE 6 ShopNotes No. 84 |