84, страница 8

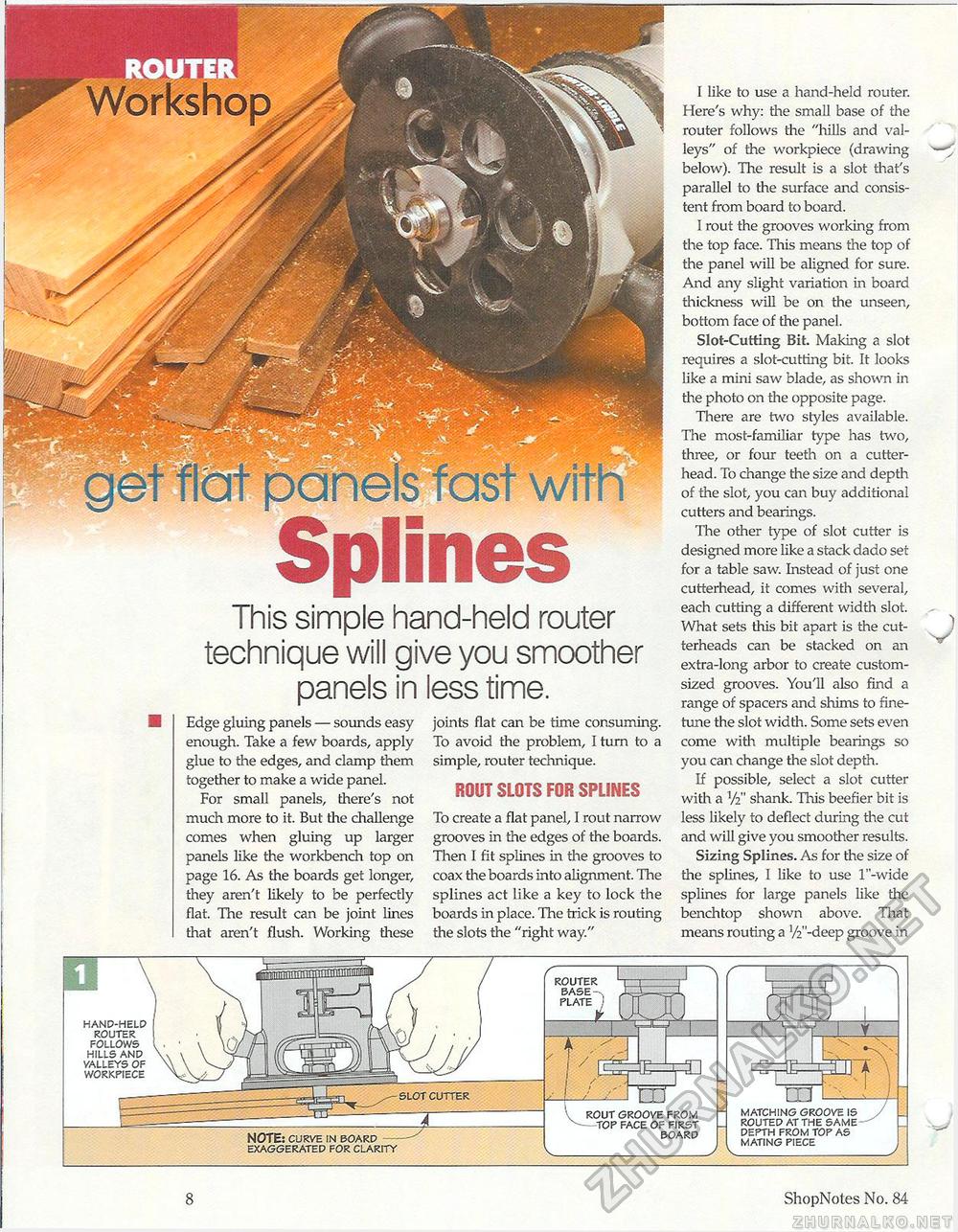

splinesThis simple hand-held router technique will give you smoother panels in less time. Edge gluing panels — sounds easy enough. Take a few boards, apply glue to the edges, and clamp them together to make a wide panel. For small panels, there's not much more to it. But the challenge comes when gluing up larger panels like the workbench top on page 16. As the boards get longer, they aren't likely to be perfectly flat. The result can be joint lines that aren't flush. Working these joints flat can be time consuming. To avoid the problem, I turn to a simple, router technique. ROUT SLOTS FOR SPLINES To create a flat panel, I rout narrow grooves in the edges of the boards. Then I fit splines in the grooves to coax the boards into alignment. The splines act like a key to lock the boards in place. The trick is routing the slots the "right way." I like to use a hand-held router. Here's why: the small base of the router follows the "hills and valleys" of the workpiece (drawing below). The result is a slot that's parallel to the surface and consistent from board to board. I rout the grooves working from the top face. This means the top of the panel will be aligned for sure. And any slight variation in board thickness will be on the unseen, bottom face of the panel. Slot-Cutting Bit. Making a slot requires a slot-cutting bit. It looks like a mini saw blade, as shown in the photo on the opposite page. There are two styles available. The most-familiar type has two, three, or four teeth on a cutter-head. To change the size and depth of the slot, you can buy additional cutters and bearings. The other type of slot cutter is designed more like a stack dado set for a table saw. Instead of just one cutterhead, it comes with several, each cutting a different width slot. What sets this bit apart is the cut-terheads can be stacked on an extra-long arbor to create custom-sized grooves. You'll also find a range of spacers and shims to fine-tune the slot width. Some sets even come with multiple bearings so you caii change the slot depth. If possible, select a slot cutter with a V2" shank. This beefier bit is less likely to deflect during the cut and will give you smoother results. Sizing Splines. As for the size of the splines, I like to use l"-wide splines for large panels like the bench top shown above. That means routing a '/V'-deep groove in 8 ShopNotes No. 84 router i—r BASE-* XU plate ! _i. V/ rout groove from top face of first board note: curve in board exaggerated for clarity hand-held router follows hills and valleys of workpiece matching groove is routed at the same depth from top as mating piece slot cutter |