85 - Router Table, страница 15

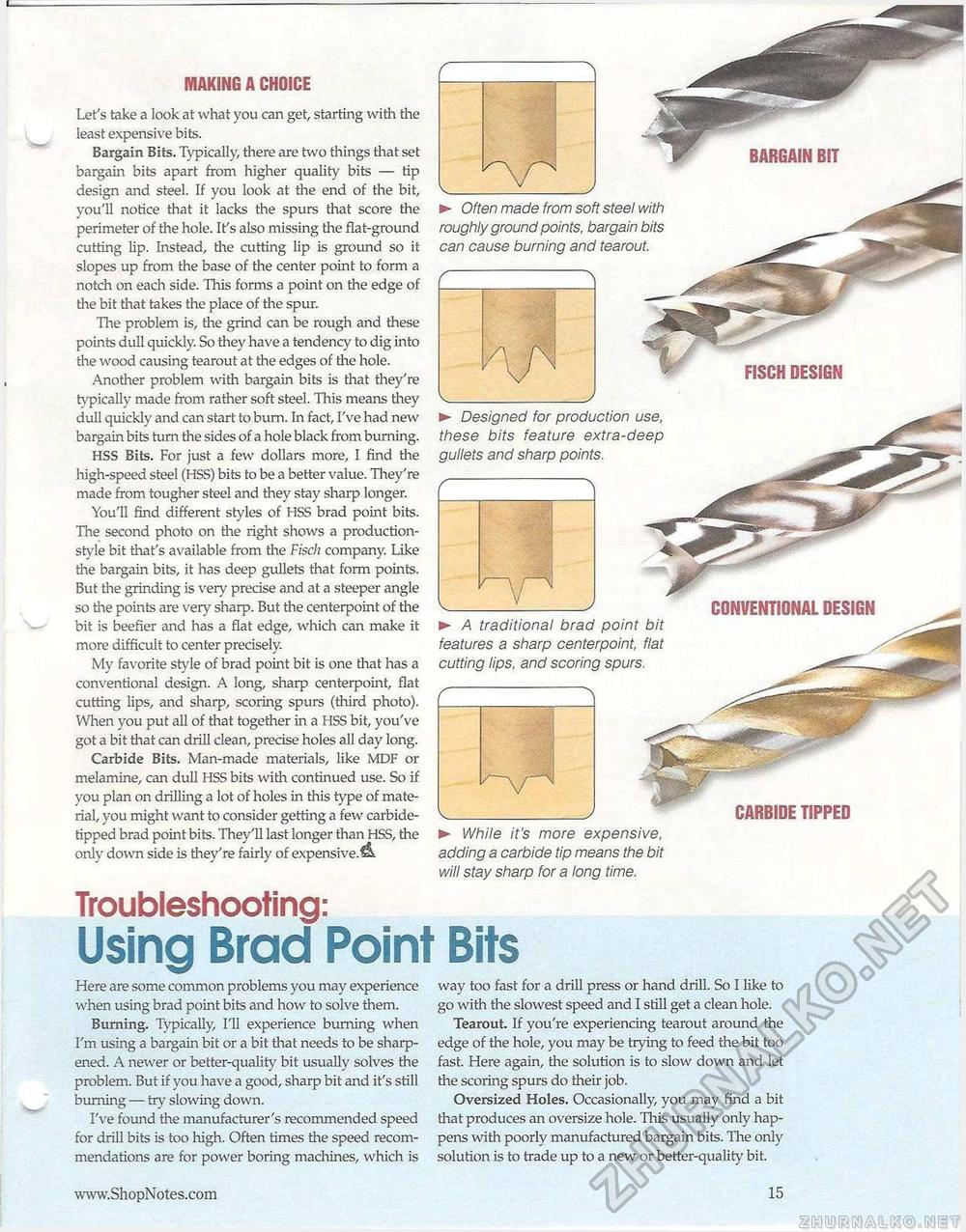

L MAKING A CHOICE Let's take a look at what you can get, starting with the least expensive bits. Bargain Bits. Typically, there are two things that set bargain bits apart from higher quality bits — tip design and steel. If you look at the end of the bit, you'll notice that it lacks the spurs that score the perimeter of the hole. It's also missing the flat-ground cutting lip. Instead, the cutting lip is ground so it slopes up from the base of the center point to form a notch on each side. This forms a point on the edge of the bit that takes the place of the spur. The problem is, the grind can be rough and these points dull quickly. So they have a tendency to dig into the wood causing tearout at the edges of the hole. Another problem with bargain bits is that they're typically made from rather soft steel. This means they dull quickly and can start to burn. In fact, I've had new bargain bits turn the sides of a hole black from burning. HSS Bits. For just a few dollars more, I find the high-speed steel (HSS) bits to be a better value. They're made from tougher steel and they stay sharp longer. You'll find different styles of HSS brad point bits. The second photo on the right shows a production-style bit that's available from the Fisch company. Like the bargain bits, it has deep gullets that form points. But the grinding is very precise and at a steeper angle so the points are very sharp. But the centerpoint of the bit is beefier and has a flat edge, which can make it more difficult to center precisely. My favorite style of brad point bit is one that has a conventional design. A long, sharp centerpoint, flat cutting lips, and sharp, scoring spurs (third photo). When you put all of that together in a HSS bit, you've got a bit that can drill clean, precise holes all day long. Carbide Bits. Man-made materials, like MDF or melamine, can dull HSS bits with continued use. So if you plan on drilling a lot of holes in this type of material, you might want to consider getting a few carbide-tipped brad point bits. They'll last longer than HSS, the only down side is they're fairly of expensive.^ Troubleshooting: Using Brad PointHere are some common problems you may experience when using brad point bits and how to solve them. Burning. Typically, I'll experience burning when I'm using a bargain bit or a bit that needs to be sharpened. A newer or better-quality bit usually solves the problem. But if you have a good, sharp bit and it's still burning — try slowing down. I've found the manufacturer's recommended speed for drill bits is too high. Often times the speed recommendations are for power boring machines, which is ► While it's more expensive, adding a carbide tip means the bit will stay sharp for a long time. Bitsway too fast for a drill press or hand drill. So I like to go with the slowest speed and I still get a clean hole. Tearout. If you're experiencing tearout around the edge of the hole, you may be trying to feed the bit too fast. Here again, the solution is to slow down and let the scoring spurs do their job. Oversized Holes. Occasionally, you may find a bit that produces an oversize hole. This usually only happens with poorly manufactured bargain bits. The only solution is to trade up to a new or better-quality bit. 15 CABBIDE TIPPED BARGAIN BIT ► Often made from soft steel with roughly ground points, bargain bits can cause burning and tearout. Designed for production use, these bits feature extra-deep gullets and sharp points. A traditional brad point bit features a sharp centerpoint, flat cutting lips, and scoring spurs. CONVENTIONAL DESIGN FISCH DESIGN |