85 - Router Table, страница 14

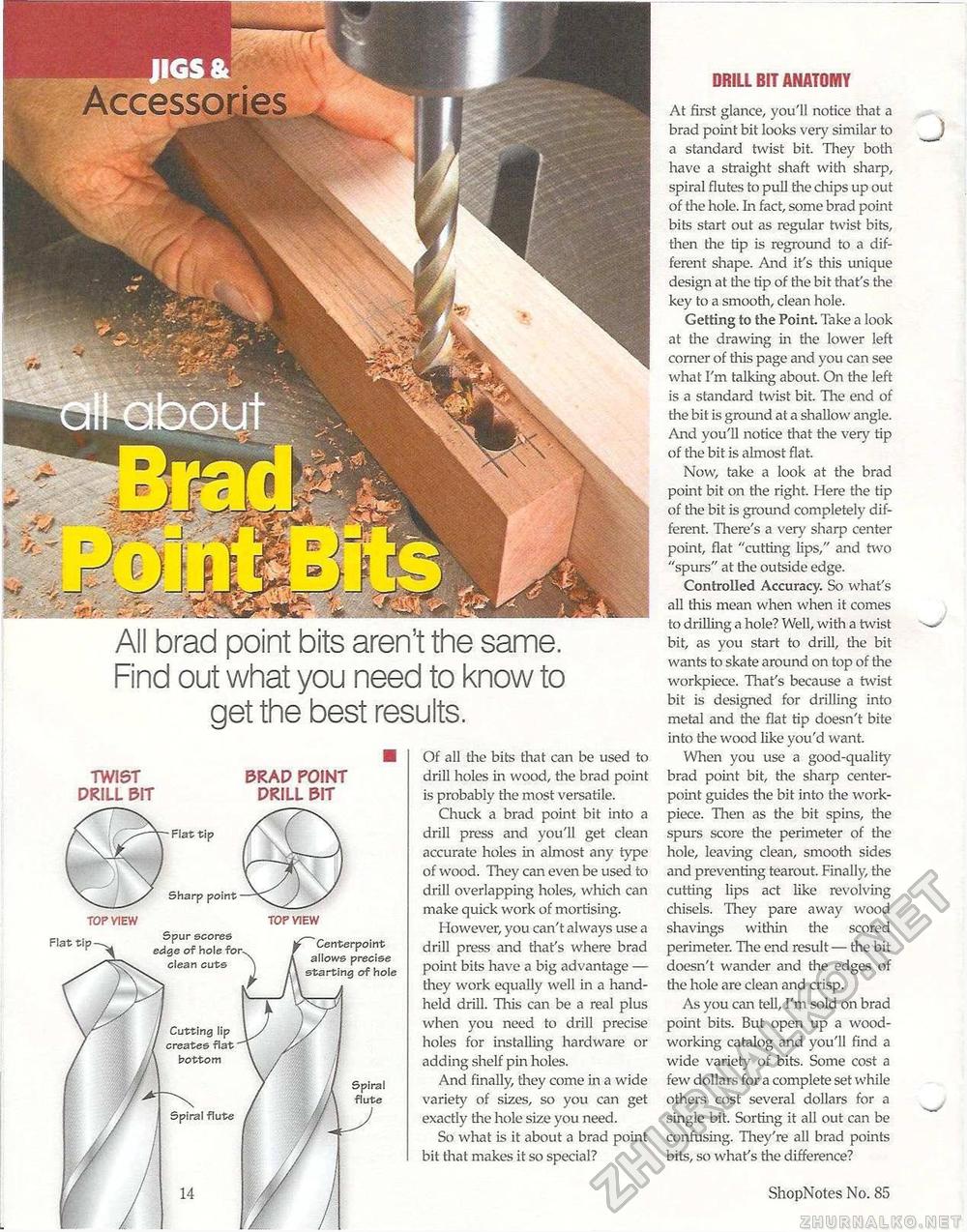

All brad point bits aren't the same. Find out what you need to know to get the best results. TWIST DRILL BIT BRAD POINT DRILL BIT TOP VIEW Flat tip- Flat tip Sharp point Spur scores edge of hole for-elean cuts Cutting lip creates flat bottom Spiral flute TOP VIEW Centerpoint allows precise starting of hole Spiral i/\ flute Of all the bits that can be used to drill holes in wood, the brad point is probably the most versatile. Chuck a brad point bit into a drill press and you'll get clean accurate holes in almost any type of wood. They can even be used to drill overlapping holes, which can make quick work of mortising. However, you can't always use a drill press and that's where brad point bits have a big advantage — they work equally well in a handheld drill. This can be a real plus when you need to drill precise holes for installing hardware or adding shelf pin holes. And finally, they come in a wide variety of sizes, so you can get exactly the hole size you need. So what is it about a brad point bit that makes it so special? DRILL BIT ANATOMY At first glance, you'll notice that a brad point bit looks very similar to a standard twist bit. They both have a straight shaft with sharp, spiral flutes to pull the chips up out of the hole. In fact, some brad point bits start out as regular twist bits, then tine tip is reground to a different shape. And it's this unique design at the tip of the bit that's the key to a smooth, clean hole. Getting to the Point. Take a look at the drawing in the lower left corner of this page and you can see what I'm talking about. On the left is a standard twist bit. The end of the bit is ground at a shallow angle. And you'll notice that the very tip of the bit is almost flat. Now, take a look at the brad point bit on the right. Here the tip of tire bit is ground completely different. There's a very sharp center point, flat "cutting hps," and two "spurs" at the outside edge. Controlled Accuracy. So what's all this mean when when it comes to drilling a hole? Well, with a twist bit, as you start to drill, the bit wants to skate around on top of the workpiece. That's because a twist bit is designed for drilling into metal and the flat tip doesn't bite into the wood like you'd want. When you use a good-quality brad point bit, the sharp center-point guides the bit into the work-piece. Then as the bit spins, the spurs score the perimeter of the hole, leaving clean, smooth sides and preventing tearout. Finally, the cutting lips act like revolving chisels. They pare away wood shavings within the scored perimeter. The end result— the bit doesn't wander and the edges of the hole are clean and crisp. As you can tell, I'm sold on brad point bits. But open up a woodworking catalog and you'll find a wide variety of bits. Some cost a few dollars for a complete set while others cost several dollars for a single bit. Sorting it all out can be confusing. They're all brad points bits, so what's the difference? 14 ShopNotes No. 85 J |