86, страница 14

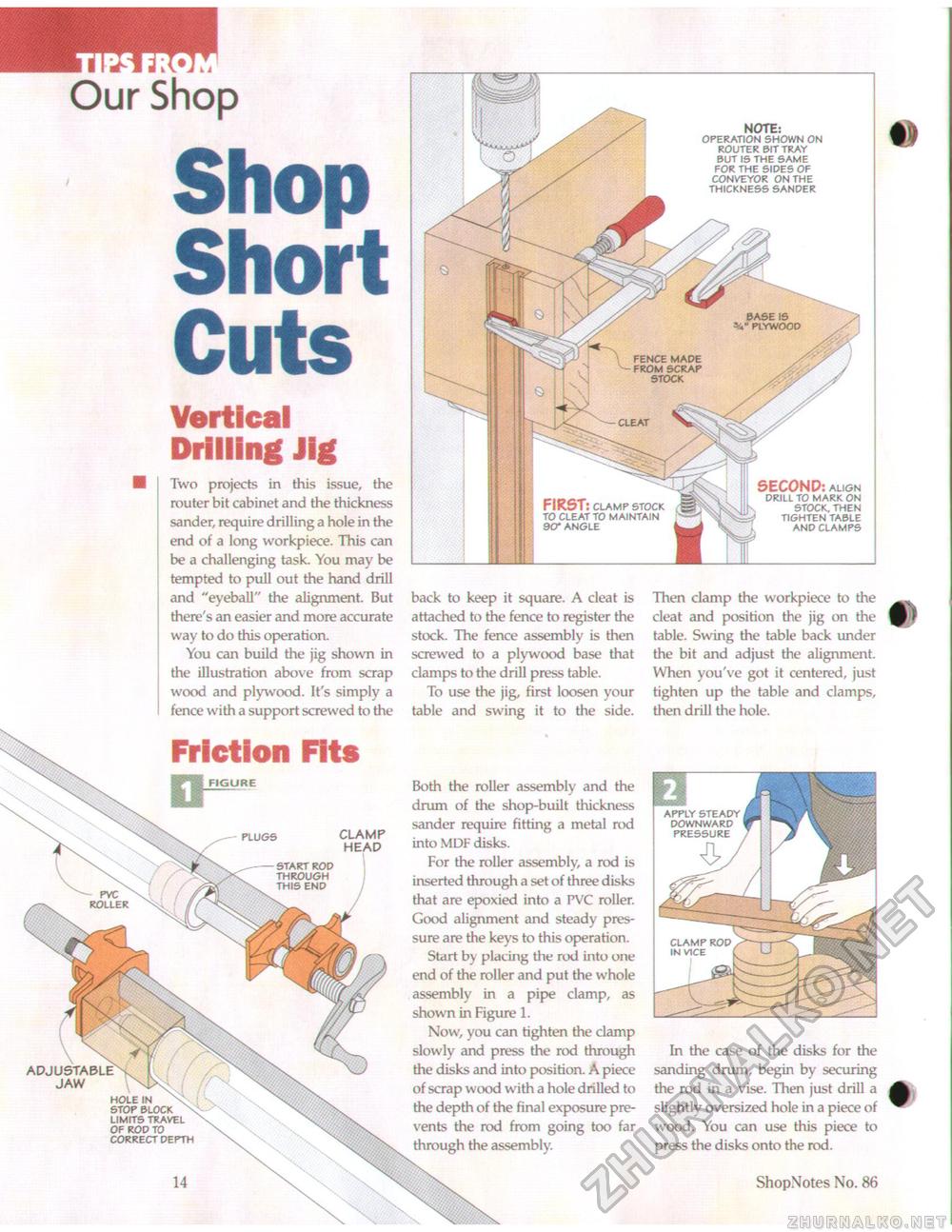

Our Shop CutsVertical Drilling Jig Two projects in this issue, the router bit cabinet and the thickness sander, require drilling a hole in the end of a long workpiece. This can be a challenging task. You may be tempted to pull out the hand drill and "eyeball" the alignment. But there's an easier and more accurate way to do this operation. You can build the jig shown in the illustration above from scrap wood and plywood. It's simply a fence with a support screwed to the NOTE: operation shown on router bit tray but is the same for the sides of conveyor on the thickness sander back to keep it square. A cleat is attached to the fence to register the stock. The fence assembly is then screwed to a plywood base that clamps to the drill press table. To use the jig, first loosen your table and swing it to the side. SECOND: align drill to mark on stock. then tighten table and clamps Then damp the workpiece to the cleat and position the jig on the table. Swing the table back under the bit and adjust the alignment. When you've got it centered, just tighten up the table and clamps, then drill the hole. In the case of the disks for the sanding drum, begin by securing the rod in a vise. Then just drill a slightly oversized hole in a piece of wood. You can use this piece to press the disks onto the rod. 14 ShopNotes No. 86 Friction Fits PIfigure Both the roller assembly and the drum of the shop-built thickness sander require fitting a metal rod into MDF disks. For the roller assembly, a rod is inserted through a set of three disks that are epoxied into a PVC roller. Good alignment and steady pressure are the keys to this operation. Start by placing the rod into one end of the roller and put the whole assembly in a pipe clamp, as shown in Figure 1. Now, you can tighten the clamp slowly and press the rod through the disks and into position. A piece of scrap wood with a hole drilled to the depth of the final exposure prevents the rod from going too far through the assembly. roller ADJ JAW hole in stop block limits travel of rod to correct depth CLAMP plugs |