87, страница 18

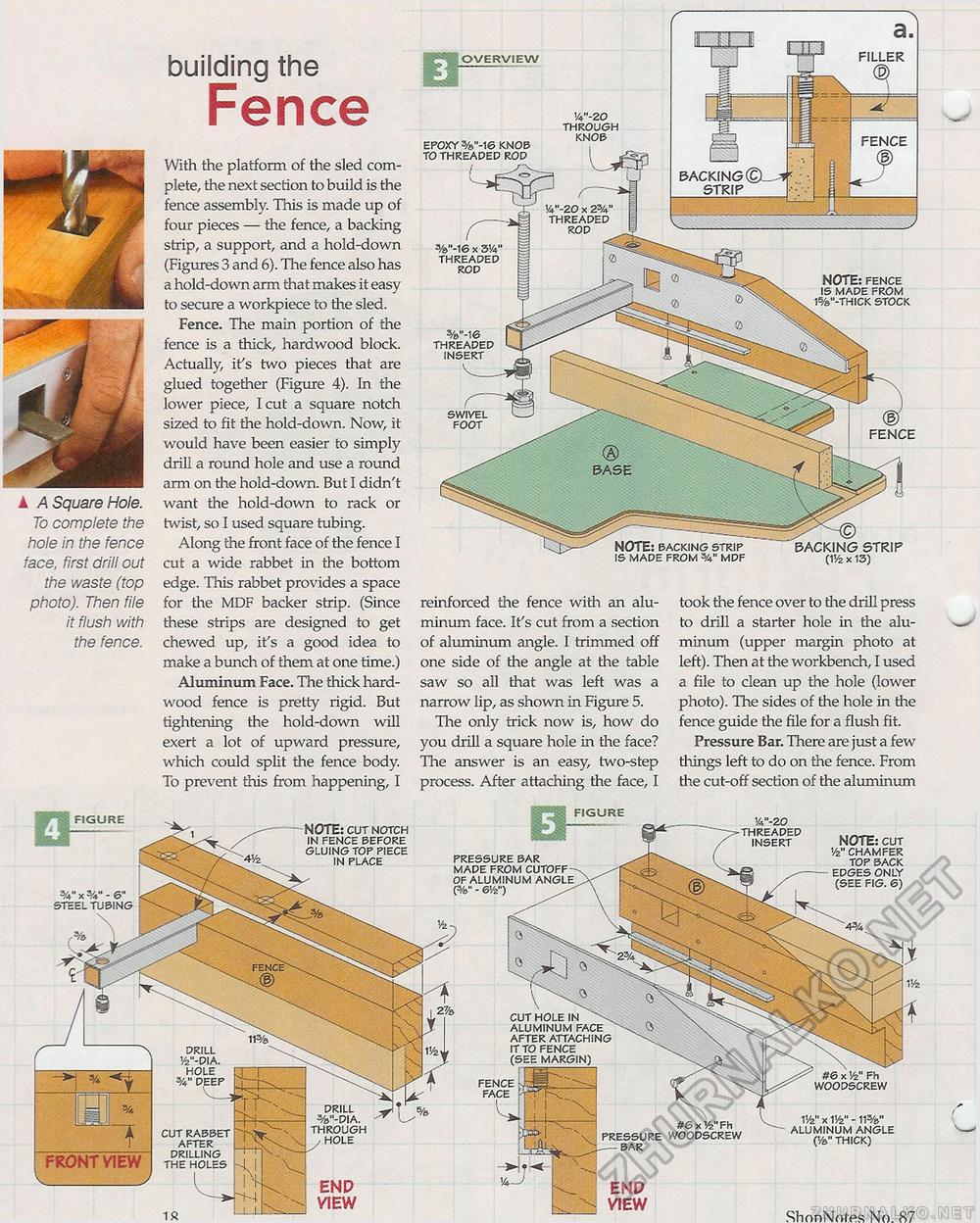

A A Square Hole. To complete the hole in the fence face, first drill out the waste (top photo). Then file it flush with the fence. building the Fence With the platform of the sled complete, the next section to build is the fence assembly. This is made up of four pieces — the fence, a backing strip, a support, and a hold-down (Figures 3 and 6). The fence also has a hold-down arm that makes it easy to secure a workpiece to the sled. Fence. The main portion of the fence is a thick, hardwood block. Actually, it's two pieces that are glued together (Figure 4). In the lower piece, I cut a square notch sized to fit the hold-down. Now, it would have been easier to simply drill a round hole and use a round arm on the hold-down. But I didn't want the hold-down to rack or twist, so I used square tubing. Along the front face of the fence I cut a wide rabbet in the bottom edge. This rabbet provides a space for the MDF backer strip. (Since these strips are designed to get chewed up, it's a good idea to make a bunch of them at one time.) Aluminum Face. The thick hardwood fence is pretty rigid. But tightening the hold-down will exert a lot of upward pressure, which could split the fence body. To prevent this from happening, I reinforced the fence with an aluminum face. It's cut from a section of aluminum angle. I trimmed off one side of the angle at the table saw so all that was left was a narrow lip, as shown in Figure 5. The only trick now is, how do you drill a square hole in the face? The answer is an easy, two-step process. After attaching the face, I took the fence over to the drill press to drill a starter hole in the aluminum (upper margin photo at left). Then at the workbench, I used a file to clean up the hole (lower photo). The sides of the hole in the fence guide the file for a flush fit. Pressure Bar. There are just a few tilings left to do on the fence. From the cut-off section of the aluminum OVERVIEW 3/e"-16 x 3'/4" threaded rod %"-16 threaded INSERT NU I e: BACKING STRIP IS MADE FROM %" MDF BACKING STRIP (1'/2 X 13) epoxy %"-16 knob to threaded rod !V'-2 0 through knob NOTE: fence is made from 1%"-thick stock FENCE a. FILLER cut hole in \ aluminum face after attaching it to fence (see margin) #6 x Vz" Fh pressure woodscrew FIGURE cut notch before top piece x - 6" steel tubing drill y2"-dia. hole deep drill %"-dia. through , hole AM; cut rabbet after drilling the holes FRONT yiEW -M pressure bar made from cutoff-of aluminum angle (%" - &/z") NOTE: cut Vz" chamfer top back edges only (see fig. 6) FIGURE 'A -20 THREADED insert #6x!6" Fh woodscrew END VIEW END VIEW W x V/z" -11%" ALUMINUM ANGLE (Vs" THICK) ShonNoles No. 87 |