87, страница 44

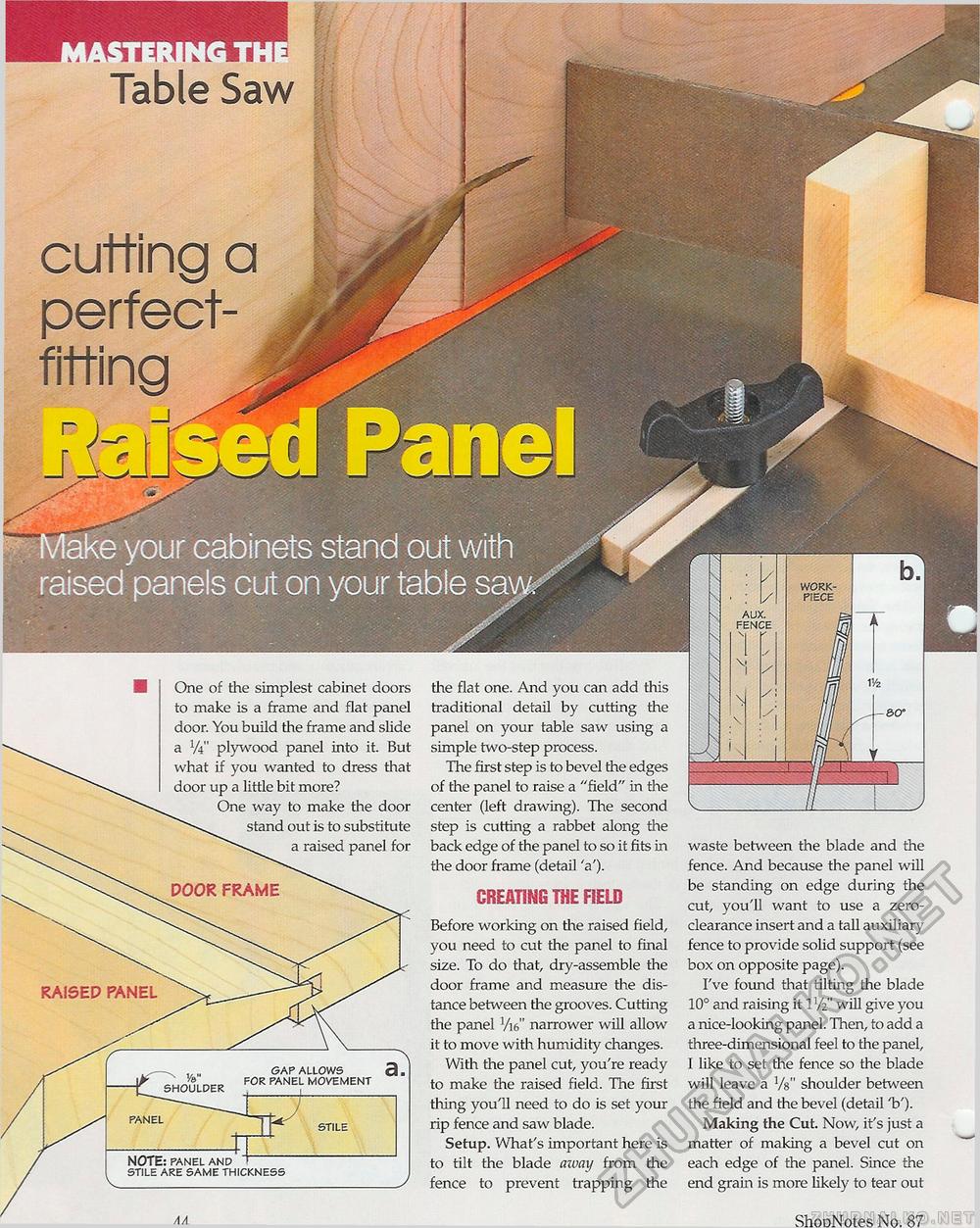

DOOR FRAME SHOULDER cutting a perfect-fitting the flat one. And you can add this traditional detail by cutting the panel on your table saw using a simple two-step process. The first step is to bevel the edges of the panel to raise a "field" in the center (left drawing). The second step is cutting a rabbet along the back edge of the panel to so it fits in the door frame (detail 'a'). CREATING THE FIELD Before working on the raised field, you need to cut the panel to final size. To do that, dry-assemble the door frame and measure the distance between the grooves. Cutting the panel VW' narrower will allow it to move with humidity changes. With the panel cut, you're ready to make the raised field. The first thing you'll need to do is set your rip fence and saw blade. Setup. What's important here is to tilt the blade away from the fence to prevent trapping the waste between the blade and the fence. And because the panel will be standing on edge during the cut, you'll want to use a zero-clearance insert and a tall auxiliary fence to provide solid support (see box on opposite page). I've found that tilting the blade 10° and raising it IV2" will give you a nice-looking panel. Then, to add a three-dimensional feel to the panel, I like to set the fence so the blade will leave a Vs" shoulder between the field and the bevel (detail 'b'). Making the Cut. Now, it's just a matter of making a bevel cut on each edge of the panel. Since the end grain is more likely to tear out 90 ShoDNotes No. 87 One of the simplest cabinet doors to make is a frame and flat panel door. You build the frame and slide a 1/4" plywood panel into it. But what if you wanted to dress that door up a little bit more? One way to make the door stand out is to substitute a raised panel for RAISED PANEL NOTE: PANEL AND ' STILE ARE SAME THICKNESS V___ PANEL GAP ALLOWS 9. FOR PANEL MOVEMENT STILE |