90 - Get the Most out of a Plunge Router, страница 26

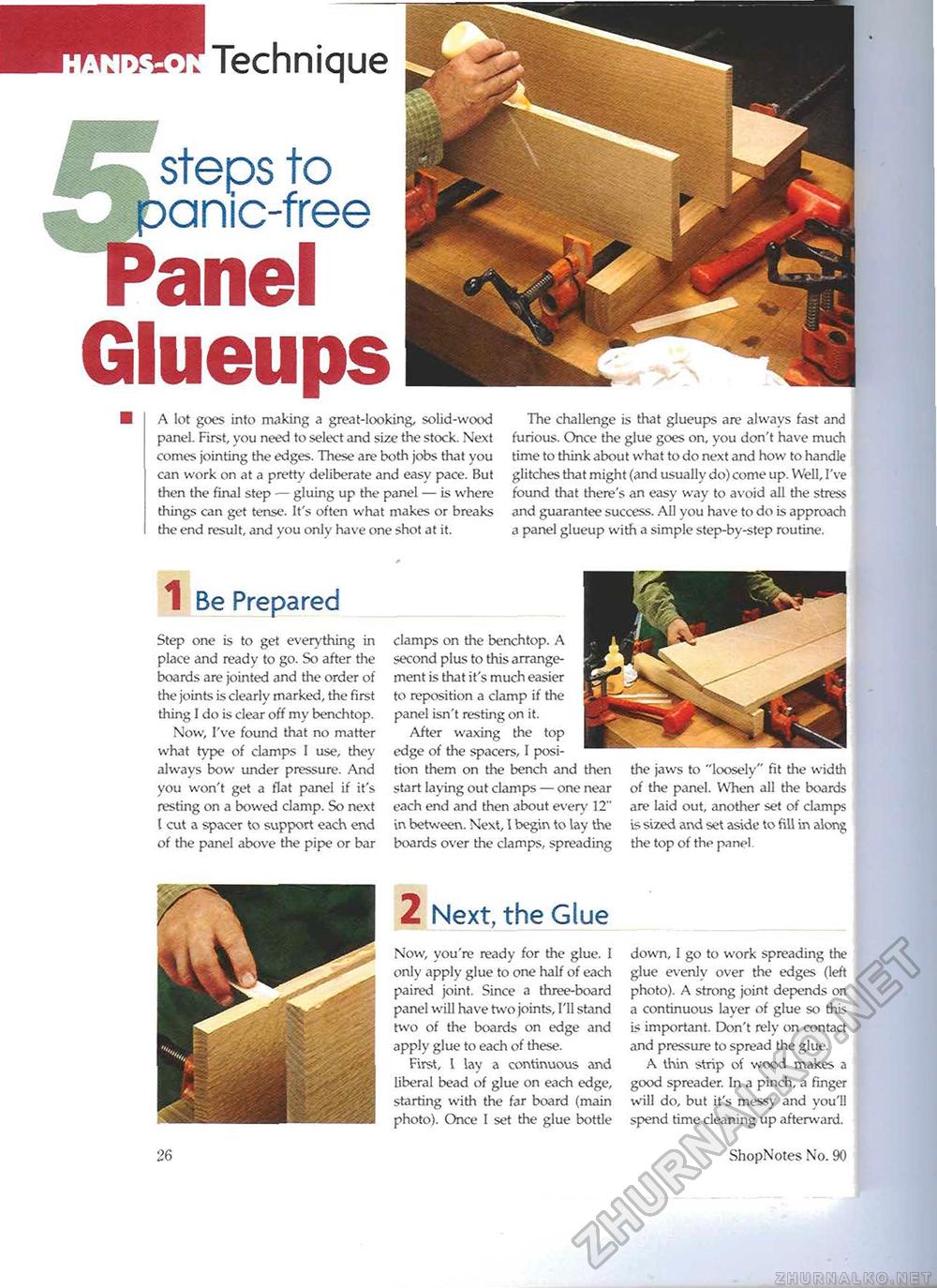

"Technique steps to panic-free HPanelGlueupsA lot goes into making a great-looking, solid-wood panel. First, you need to select and size the stock. Next comes jointing the edges. These are both jobs that you can work on at a pretty deliberate and easy pace. But then the final step — gluing up the panel — is where things can get tense. It's often what makes or breaks the end result, and you only have one shot at it. The challenge is that glueups are always fast and furious. Once the glue goes on, you don't have much time to think about what to do next and how to handle glitches that might (and usually do) come up. Well, I've found that there's an easy way to avoid all the stress and guarantee success. All you have to do is approach a panel glueup with a simple step-by-step routine. 1 Be Prepared Step one is to get everything in place and ready to go. So after the boards are jointed and the order of the joints is clearly marked, the first thing I do is clear off my benchtop. Now, I've found that no matter what type of clamps I use, they always bow under pressure. And you won't get a flat panel if it's resting on a bowed clamp. So next I cut a spacer to support each end of the panel above the pipe or bar clamps on the benchtop. A second plus to this arrangement is that it's much easier to reposition a clamp if the panel isn't resting on it. After waxing the top edge of the spacers, I position them on the bench and then start laying out clamps — one near each end and then about every 12" in between. Next, I begin to lay the boards over the clamps, spreading the jaws to "loosely" fit the width of the panel. When all the boards are laid out, another set of clamps is sized and set aside to fill in along the top of the panel. 2 Next, the Glue Now, you're ready for the glue. I only apply glue to one half of each paired joint. Since a three-board panel will have two joints, I'll stand two of the boards on edge and apply glue to each of these. First, 1 lay a continuous and liberal bead of glue on each edge, starting with the far board (main photo). Once 1 set the glue bottle down, I go to work spreading the glue evenly over the edges (left photo). A strong joint depends on a continuous layer of glue so this is important. Don't rely on contact and pressure to spread the glue. A thin strip of wood makes a good spreader. In a pinch, a finger will do, but it's messy and you'll spend time cleaning up afterward. 26 ShopNotes No. 90 |