90 - Get the Most out of a Plunge Router, страница 40

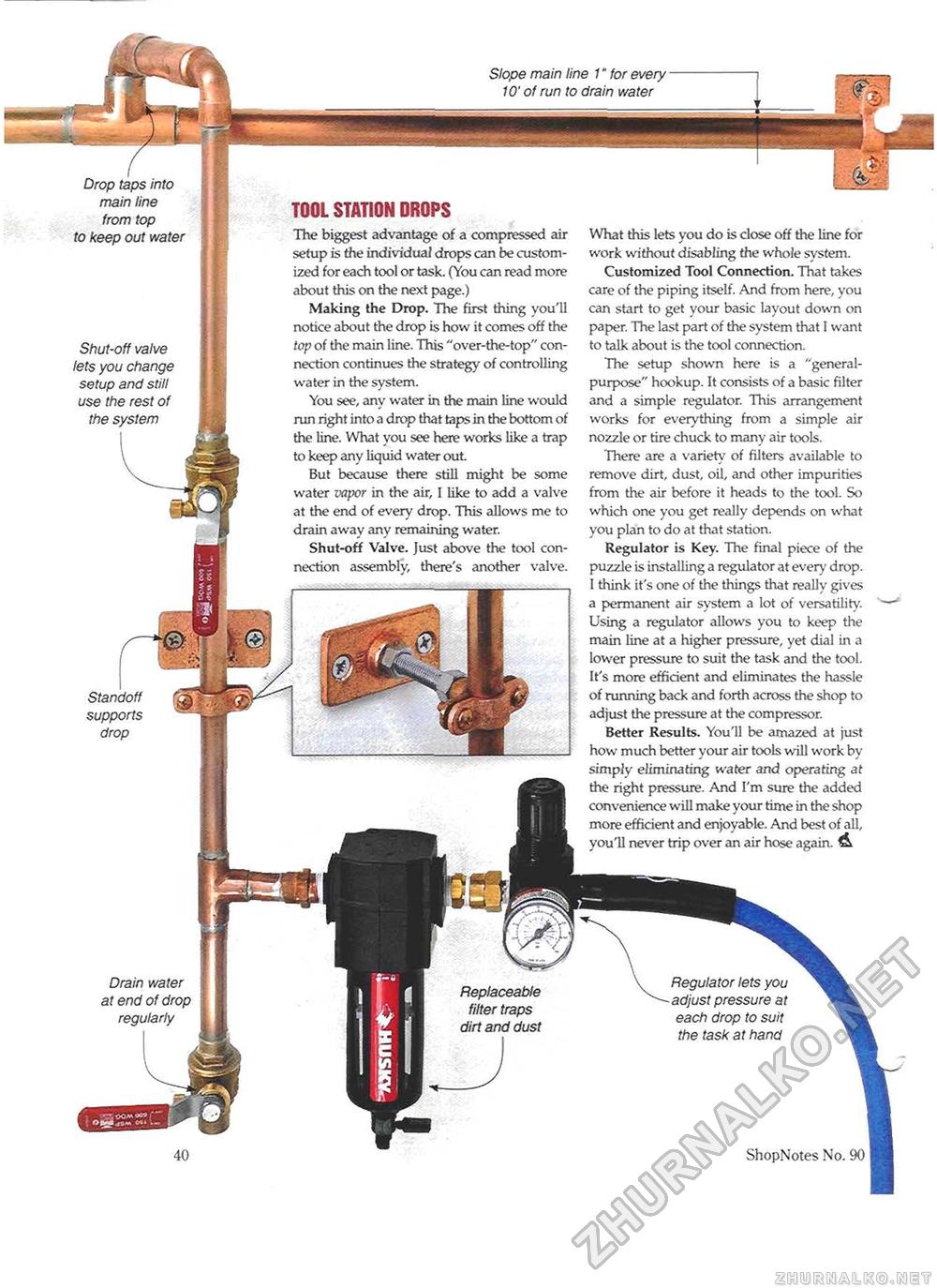

Standoff supports drop Replaceable filter traps dirt and dust Regulator lets you -adjust pressure at each drop to suit the task at hand ShopNotes No. 90 I Drain water at end of drop regularly Slope main line 1" for every 10' of run to drain water What this lets you do is close off the line for work without disabling the whole system. Customized Tool Connection. That takes care of the piping itself. And from here, you can start to get your basic layout down on paper. The last part of the system that 1 want to talk about is the tool connection. The setup shown here is a general-purpose" hookup. It consists of a basic filter and a simple regulator. This arrangement works for everything from a simple air nozzle or tire chuck to many air tools. There are a variety of filters available to remove dirt, dust, oil, and other impurities from the air before it heads to the tool. So which one you get really depends on what you plan to do at that station. Regulator is Key. The final piece of the puzzle is installing a regulator at every drop. I think it's one of the things that really gives a permanent air system a lot of versatility. Using a regulator allows you to keep the main line at a higher pressure, yet dial in a lower pressure to suit the task and the tool. It's more efficient and eliminates the hassle of running back and forth across the shop to adjust the pressure at the compressor. Better Results. You'll be amazed at just how much better your air tools will work by simply eliminating water and operating at the right pressure. And I'm sure the added convenience will make your time in the shop more efficient and enjoyable. And best of all, you'll never trip over an air hose again. A TOOL STATION DROPS The biggest advantage of a compressed air setup is the individual drops can be customized for each tool or task. (You can read more about this on the next page.) Making the Drop. The first thing you'll notice about the drop is how it comes off the top of the main line. This "over-the-top" connection continues the strategy of controlling water in the system. You see, any water in the main line would run right into a drop that taps in the bottom of the line. What you see here works like a trap to keep any liquid water out But because there still might be some water vapor in the air, I like to add a valve at the end of every drop. This allows me to drain away any remaining water. Shut-off Valve. Just above the tool connection assembly, there's another valve. Drop taps into main line from top to keep out water Shut-off valve lets you change setup and still use the rest of the system |