90 - Get the Most out of a Plunge Router, страница 42

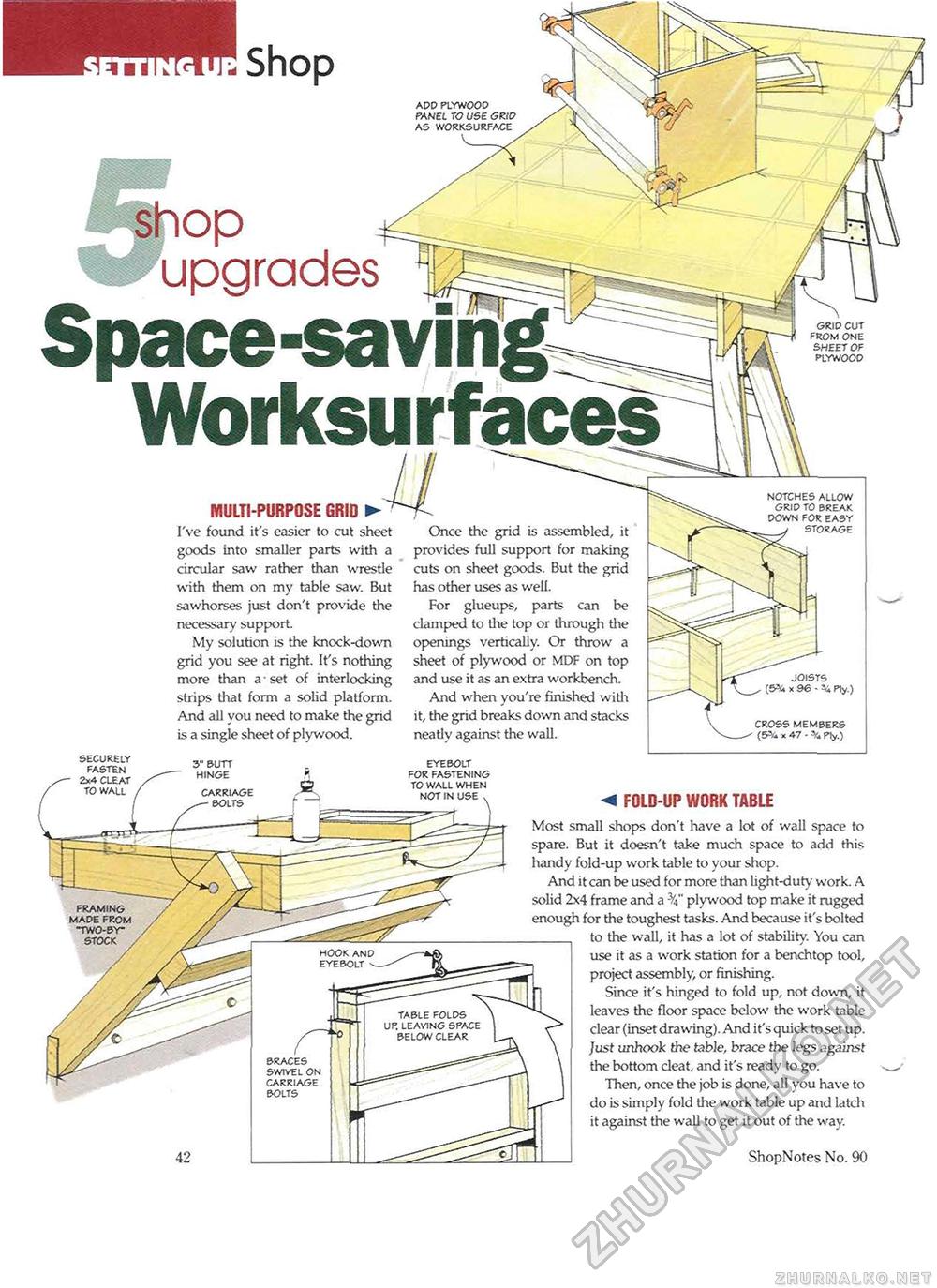

ADD PLYWOOD PANEL TO USE GRIO AS WORKSURFACE GRID CUT FROM ONE SHEET OF PLYWOOD I've found it's easier to cut sheet goods into smaller parts with a circular saw rather than wrestle with them on my table saw. But sawhorses just don't provide the necessary support. My solution is the knock-down grid you see at right. It's nothing more than a • set of interlocking strips that form a solid platform. And all you need to make the grid is a single sheet of plywood. Once the grid is assembled, it provides full support for making cuts on sheet goods. But the grid has other uses as well. For glueups, parts can be clamped to the top or through the openings vertically. Or throw a sheet of plywood or MDF on top and use it as an extra workbench. And when you're finished with it, the grid breaks down and stacks neatly against the wall. CROSS MEMBERS (5=!4 * 47 • Ply.) JOISTS (5*4 X 90 - 'A Ply.) SECURELY FASTEN < FOLD-UP WORK TABLE 42 ShopNotes No. 90 3" BUTT EYE BOLT FOR FASTENING TO WALL WHEN MADE FROM -TWO-BY- stock SWIVEL ON CARRIAGE BOLTS Most small shops don't have a lot of wall space to spare. But it doesn't take much space to add this handy fold-up work table to your shop. And it can be used for more than light-duty work. A solid 2x4 frame and a -V plywood top make it rugged enough for the toughest tasks. And because it's bolted to the wall, it has a lot of stability. You can use it as a work station for a benchtop tool, project assembly, or finishing. Since it's hinged to fold up, not down, it leaves the floor space below the work table clear (inset drawing). And it's quick to set up. Just unh(x>k the table, brace the legs against the bottom cleat, and it's ready to go. Then, once the job is done, all you have to do is simply fold the work table up and latch it against the wall to get it out of the way. HOOK AND EYE BOLT |