90 - Get the Most out of a Plunge Router, страница 44

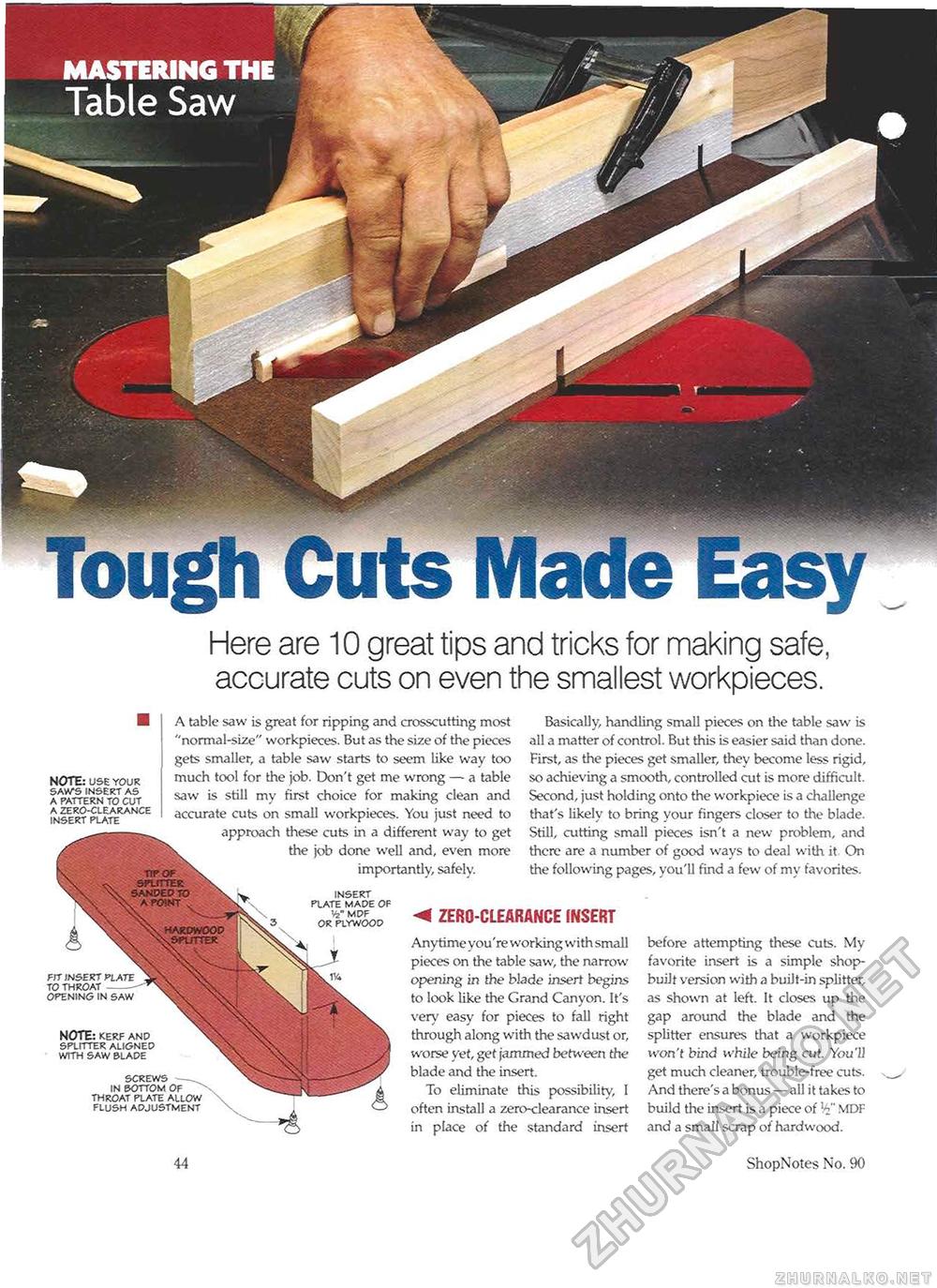

Here are 10 great tips and tricks for making safe, accurate cuts on even the smallest workpieces. NOTE: use your saws insert as a pattern to cut a zero-clearance insert plate before attempting these cuts. My favorite insert is a simple shop-built version with a built-in splitter, as shown at left. It closes up the gap around the blade and the splitter ensures that a workpiece won't bind while being cut. You'll get much cleaner, trouble-free cuts. And there's a bonus — all it takes to build the insert is a piece of Vz" MDF and a small scrap of hardwood. A table saw is great for ripping and crosscutting most "normal-size" workpieces. But as the size of the pieces gets smaller, a table saw starts to seem like way too much tool for the job. Don't get me wrong — a table saw is still my first choice for making clean and accurate cuts on small workpieces. You just need to approach these cuts in a different way to get the job done well and, even more importantly, safely. Basically, handling small pieces on the table saw is all a matter of control. But this is easier said than done. First, as the pieces get smaller, they become less rigid, so achieving a smooth, controlled ait is more difficult. Second, just holding onto the workpiece is a challenge that's likely to bring your fingers closer to the blade. Still, cutting small pieces isn't a new problem, and there are a number of good ways to deal with it On the following pages, you'll find a few of my favorites. M ZERO-CLEARANCE INSERT Anytime you're working with small pieces on the table saw, the narrow opening in the blade insert begins to look like the Grand Canyon. It's very easy for pieces to fall right through along with the sawdust or, worse yet, get jammed between the blade and the insert. To eliminate this possibility, I often install a zero-clearance insert in place of the standard insert insert plate made of Vi" mdf or plywood FIT insert to throat opening in saw NOTE: kerf and splitter aligned with saw blade screws in bottom of throat plate allow flush adjustment 44 ShopNotes No. 90 |