90 - Get the Most out of a Plunge Router, страница 47

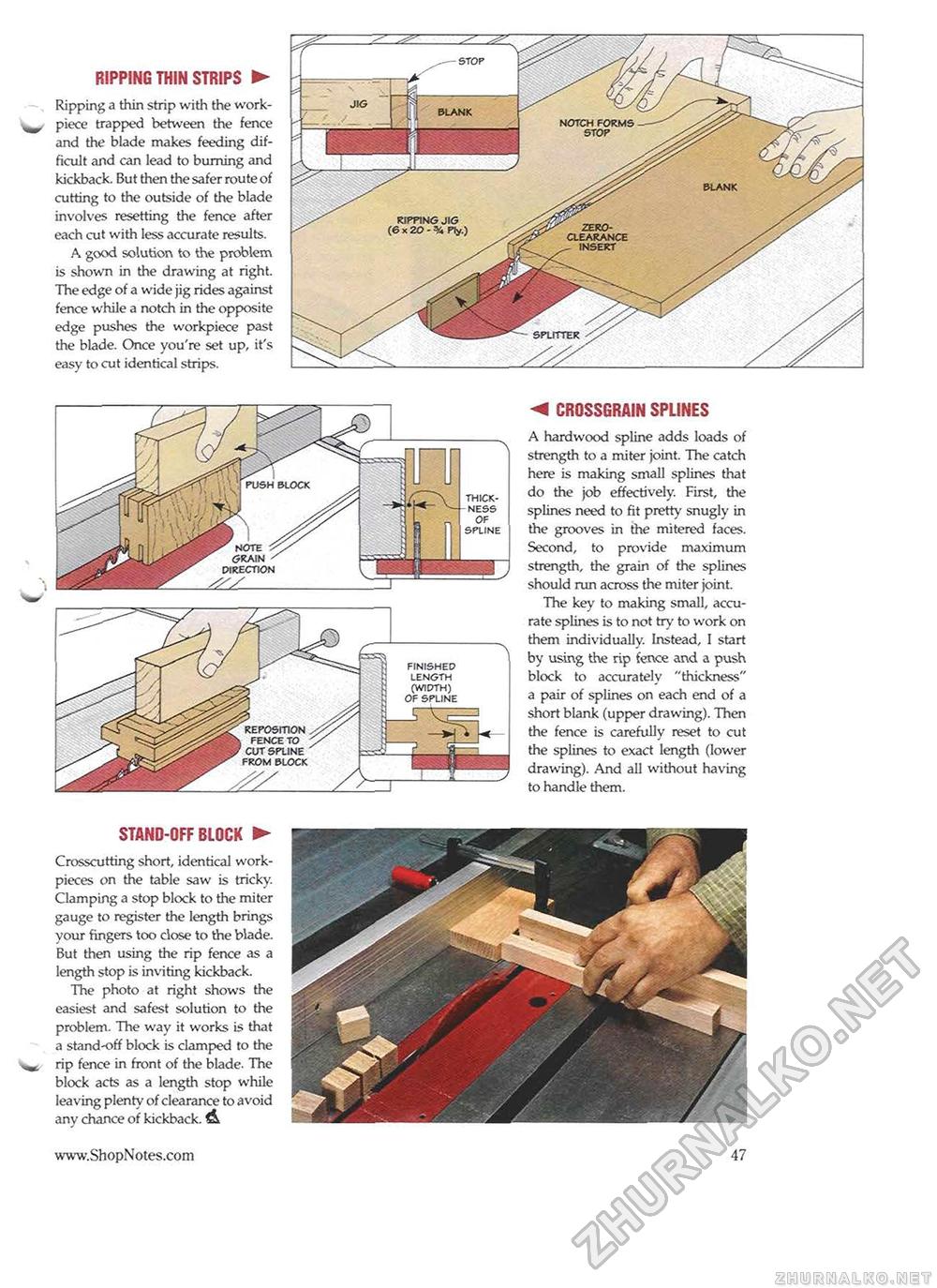

RIPPING THIN STRIPS ► Ripping a thin strip with the work-w piece trapped between the fence and the blade makes feeding difficult and can lead to burning and kickback. But then the safer route of cutting to the outside of the blade involves resetting the fence after each cut with less accurate results. A good solution to the problem is shown in the drawing at right. The edge of a wide jig rides against fence while a notch in the opposite edge pushes the workpiece past the blade. Once you're set up, it's easy to cut identical strips. BLANK NOTCH FORMS STOP BLANK RIPPING JIG (6 x 2D - % Ply.) ZERO-CLEARANCE _ INSERT THICKNESS OF SPLINE CROSSGRAIN SPLINES A hardwood spline adds loads of strength to a miter joint. The catch here is making small splines that do the job effectively. First, the splines need to fit pretty snugly in the grooves in the mitered faces. Second, to provide maximum strength, the grain of the splines should run across the miter joint. The key to making small, accurate splines is to not try to work on them individually. Instead, I start by using the rip fence and a push block to accurately "thickness" a pair of splines on each end of a short blank (upper drawing). Then the fence is carefully reset to cut the splines to exact length (lower drawing). And all without having to handle them. STAND-OFF BLOCK ► Crosscutting short, identical work-pieces on the table saw is tricky-Clamping a stop block to the miter gauge to register the length brings your fingers too close to the blade. But then using the rip fence as a length stop is inviting kickback. The photo at right shows the easiest and safest solution to the problem. The way it works is that a stand-off block is clamped to the ^ rip fence in front of the blade. The block acts as a length stop while leaving plenty of clearance to avoid any chance of kickback. 47 |