90 - Get the Most out of a Plunge Router, страница 45

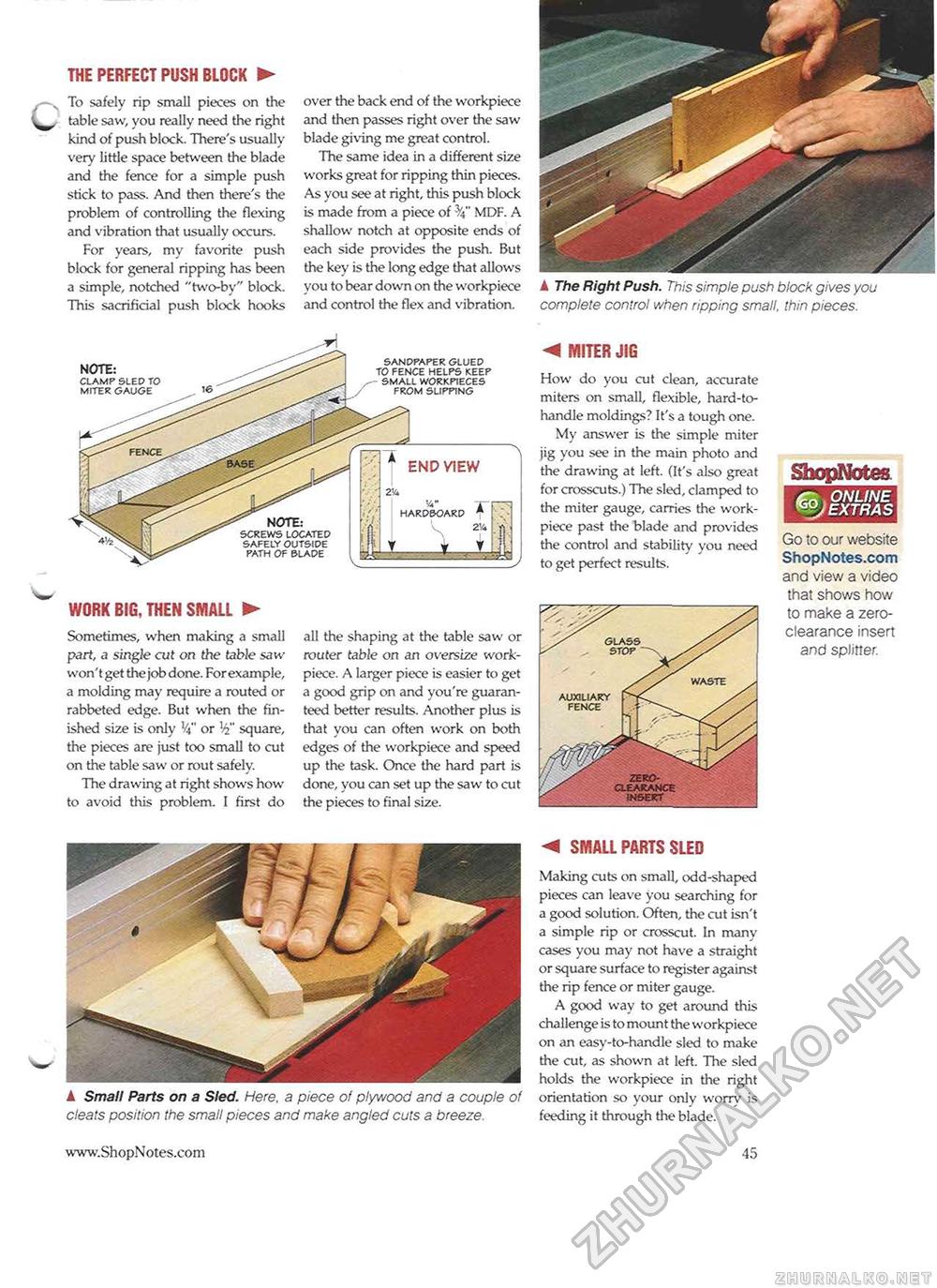

THE PERFECT PUSH BLOCK ► . To safely rip small pieces on the table saw, you really need the right kind of push block. There's usually very little space between the blade and the fence for a simple push stick to pass. And then there's the problem of controlling the flexing and vibration that usually occurs. For years, my favorite push block for general ripping has been a simple, notched "two-by" block. This sacrificial push block hooks over the back end of the workpiece and then passes right over the saw blade giving me great control. The same idea in a different size works great for ripping thin pieces. As you see at right, this push block is made from a piece of MDF. A shallow notch at opposite ends of each side provides the push. But the key is the long edge that allows you to bear down on the workpiece and control the flex and vibration. A The Right Push. This simple push block gives you complete control when ripping small, thin pieces. ShopNotes M MITER JIG How do you cut clean, accurate miters on small, flexible, hard-to-handle moldings? It's a tough one. My answer is the simple miter jig you see in the main photo and the drawing at left. (It's also great for crosscuts.) The sled, clamped to the miter gauge, carries the work-piece past the blade and prov ides the control and stability you need to get perfect results. M SMALL PARTS SLED Making cuts on small, odd-shaped pieces can leave you searching for a good solution. Often, the cut isn't a simple rip or crosscut. In many cases you may not have a straight or square surface to register against the rip fence or miter gauge. A good way to get around this challenge is to mount the workpiece on an easy-to-handle sled to make the cut, as shown at left. The sled holds the workpiece in the right orientation so your only worry is feeding it through the blade. Go to our website ShopNotes.com and view a video that shows how to make a zero-clearance insert and splitter. WORK BIG, THEN SMALL ► Sometimes, when making a small part, a single cut on the table saw won't get the job done. For example, a molding may require a routed or rabbeted edge. But when the finished size is only V4" or li" square, the pieces are just too small to cut on the table saw or rout safely. The drawing at right shows how-to avoid this problem. I first do all the shaping at the table saw or router table on an oversize work-piece. A larger piece is easier to get a good grip on and you're guaranteed better results. Another plus is that you can often work on both edges of the workpiece and speed up the task. Once the hard part is done, you can set up the saw to cut the pieces to final size. A Small Parts on a Sled. Here, a piece of plywood and a couple of cleats position the small pieces and make angled cuts a breeze. SANDPAPER GLUED TO FENCE HELPS KEEP SMALL W0RKP1ECES FROM SLIPPING NOTE: CLAMP SLED TO MITER GAUGE AUXILIARY FENCE 45 |