93, страница 50

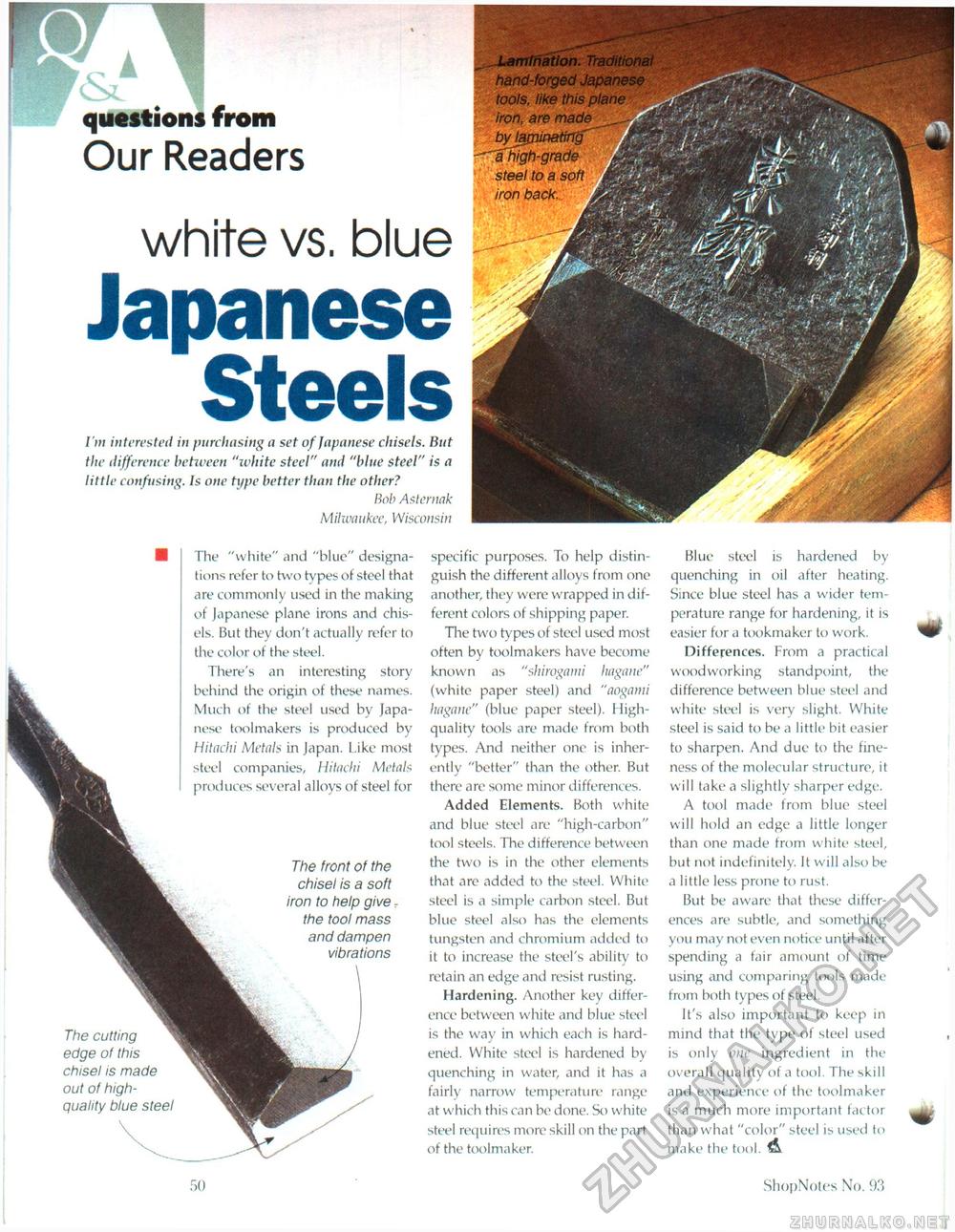

Blue steel is hardened by quenching in oil after heating. Since blue steel has a wider temperature range for hardening, it is easier for a tookmaker to work. Differences. From a practical woodworking stand point, the difference between blue steel and white steel is very slight. White steel is said to be a little bit easier to sharpen. And due to the fineness of the molecular structure, it will take a slightly sharper edge. A tool made from blue steel will hold an edge a little longer than one made from white steel, but not indefinitely. It will also be a little less prone to rust. But be aware that these differences are subtle, and something you may not even notice until after spending a fair amount of time using and comparing tools made from both types of steel. It's also important to keep in mind that the type of steel used is only one ingredient in the overall quality of a tool. The skill and experience of the toolmaker is a much more important factor than what "color" steel is used to make the tool. a from Our Readers white vs. blueJapanese SteelsI'm interested in purchasing a set of Japanese chisels. But the difference between "white steel'' and "blue steel" is a little confusing. Is one type better than the other? Bob Asternak Milivaukee, Wisconsin Lamination. Traditional hand-forged Japanese tools, like this plane specific purposes. To help distinguish the different alloys from one another, they were wrapped in different colors of shipping paper. The two types of steel used most often by toolmakers have become known as "shirogami hagane" (white paper steel) and "aogami hagane" (blue paper steel). High-quality tools are made from both types. And neither one is inherently "better" than the other. But there are some minor differences. Added Elements. Both white and blue steel are "high-carbon" tool steels. The difference between the two is in the other elements that are added to the steel. White steel is a simple carbon steel. But blue steel also has the elements tungsten and chromium added to it to increase the steel's ability to retain an edge and resist rusting. Hardening. Another key difference between white and blue steel is the way in which each is hardened. White steel is hardened by quenching in water, and it has a fairly narrow temperature range at which this can be done. So white steel requires more skill on the part of the toolmaker. The "white" and "blue" designations refer to two tvpes of steel that are commonly used in the making of Japanese plane irons and chisels. But they don't actually refer to the color of the steel. There's an interesting story behind the origin of these names. Much of the steel used by Japanese toolmakers is produced by Hitachi Metals in Japan. Like most steel companies, Hitachi Metals produces several alloys of steel for The front of the chisel is a soft iron to help give r the tool mass and dampen vibrations The cutting edge of this chisel is made out of high-quality blue steel 50 ShopNotes No. 93 |