94, страница 12

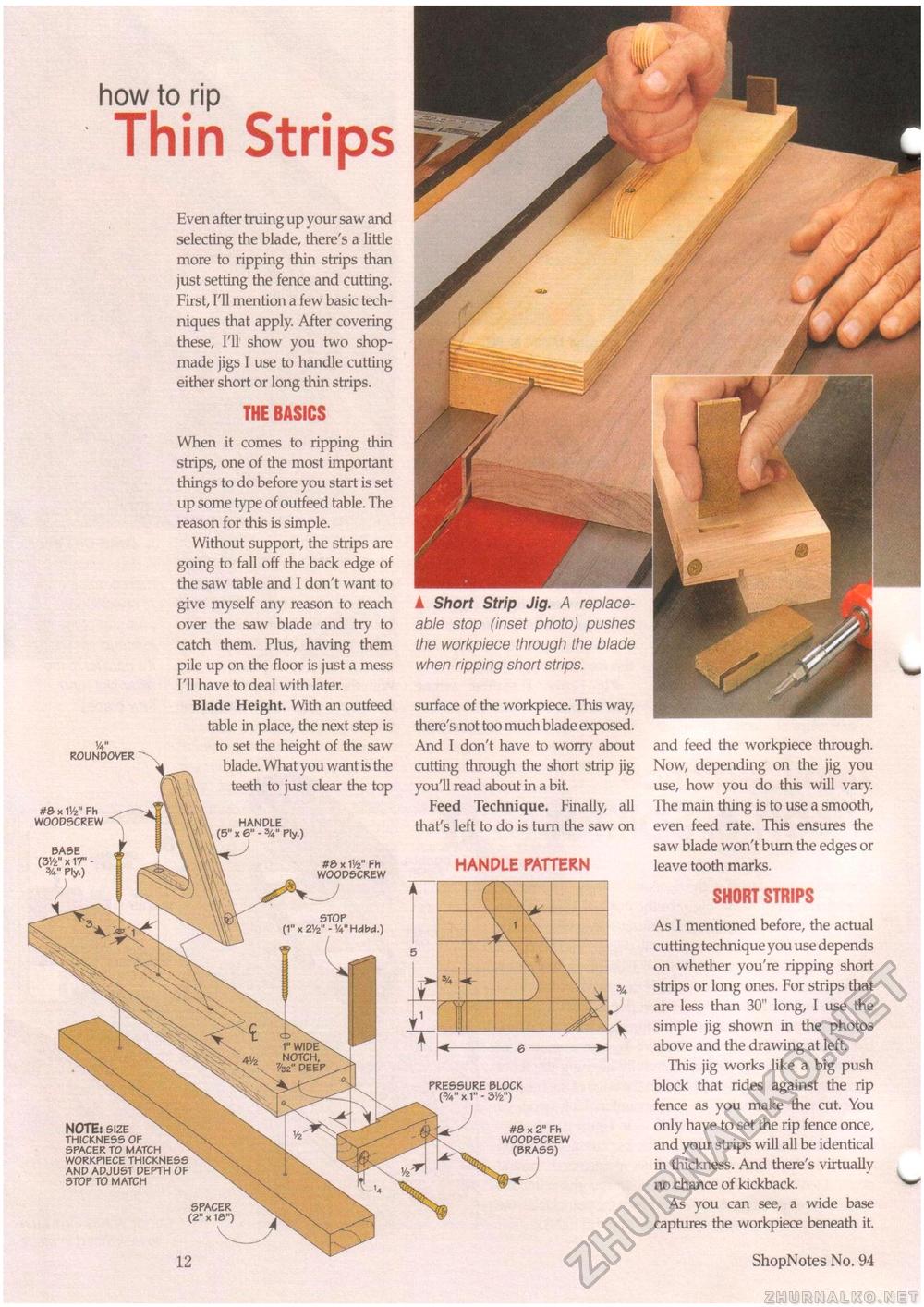

how to rip Thin StripsEven after truing up your saw and selecting the blade, there's a little more to ripping thin strips than just setting the fence and cutting. First, I'll mention a few basic techniques that apply. After covering these, I'll show you two shop-made jigs I use to handle cutting either short or long thin strips. THE BASICS When it comes to ripping thin strips, one of the most important things to do before you start is set up some type of outfeed table. The reason for this is simple. Without support, the strips are going to fall off the back edge of the saw table and I don't want to give myself any reason to reach over the saw blade and try to catch them. Plus, having them pile up on the floor is just a mess I'll have to deal with later. Blade Height. With an outfeed table in place, the next step is to set the height of the saw blade. What you want is the teeth to just clear the top ▲ Short Strip Jig. A replaceable stop (inset photo) pushes the workpiece through the blade when ripping short strips. surface of the workpiece. This way, there's not too much blade exposed. And I don't have to worry about cutting through the short strip jig you'll read about in a bit. Feed Technique. Finally, all that's left to do is turn the saw on HANDLE PATTERN ROUNDOVER #8> x 1'/2" Fh w00d5crew handle x 6" - %" Ply.) base (3'/Z" x 17" - #& x IV2" Fh woodscrew stop (1"x2V2"-W'Hdbd.) 3'4 y/z") #& x 2" Fh woodscrew ) NOTE: size thickness of spacer to match workpiece thickness and adjust depth of stop to match spacer (2" x 16") and feed the workpiece through. Now, depending on the jig you use, how you do this will vary. The main thing is to use a smooth, even feed rate. This ensures the saw blade won't burn the edges or leave tooth marks. SHORT STRIPS As I mentioned before, the actual cutting technique you use depends on whether you're ripping short strips or long ones. For strips that are less than 30" long, I use the simple jig shown in the photos above and the drawing at left. This jig works like a big push block that rides against the rip fence as you make the cut. You only have to set the rip fence once, and your strips will all be identical in thickness. And there's virtually no chance of kickback. As you can see, a wide base captures the workpiece beneath it. 12 ShopNotes No. 94 |