Woodworker's Journal 101-Projects-for-Woodworkers, страница 131

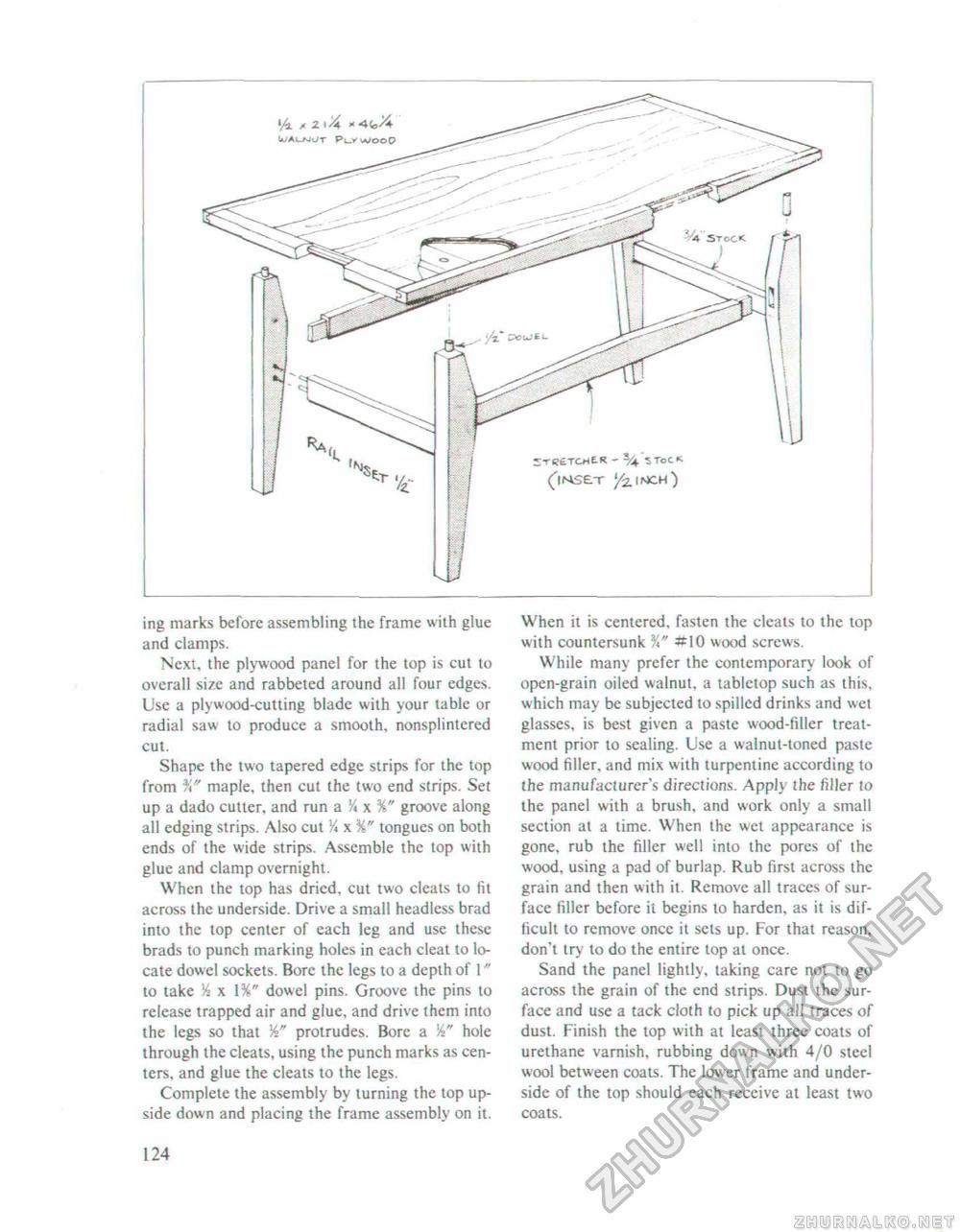

ing marks before assembling the frame with glue and clamps. Next, the plywood panel for the top is cut to overall size and rabbeted around all four edges. Use a plywood-cutting blade with your table or radial saw to produce a smooth, nonsplintered cut. Shape the two tapered edge strips for the top from maple, then cut the two end strips. Set up a dado cutter, and run a % x %" groove along all edging strips. Also cut Y* x %" tongues on both ends of the wide strips. Assemble the top with glue and clamp overnight. When the top has dried, cut two clcats to fit across the underside. Drive a small headless brad into the top center of each leg and use these brads to punch marking holes in each cleat to locate dowel sockets. Bore the legs to a depth of 1" to take Yt x dowel pins. Groove the pins to release trapped air and glue, and drive them into the legs so that Yi" protrudes. Bore a hole through the cleats, using the punch marks as centers, and glue the cleats to the legs. Complete the assembly by turning the top upside down and placing the frame assembly on it. When it is centered, fasten the cleats to the lop with countersunk %" ^10 wood screws. While many prefer the contemporary look of open-grain oiled walnut, a tabletop such as this, which may be subjected to spilled drinks and wet glasses, is best given a paste wood-filler treatment prior to sealing. Use a walnut-toned paste wood filler, and mix with turpentine according to the manufacturer's directions. Apply the filler to the panel with a brush, and work only a small section at a time. When the wet appearance is gone, rub the filler well into the pores of the wood, using a pad of burlap. Rub first across the grain and then with it. Remove all traces of surface filler before it begins to harden, as it is difficult to remove once it sets up. For that reason, don't try to do the entire lop at once. Sand the panel lightly, taking care not to go across the grain of the end strips. Dust the surface and use a tack cloth to pick up all traces of dust. Finish the top with at least three coats of urethane varnish, rubbing down with 4/0 steel wool between coats. The lower frame and underside of the top should each receive at least two coats. 124 |