Woodworker's Journal 101-Projects-for-Woodworkers, страница 16

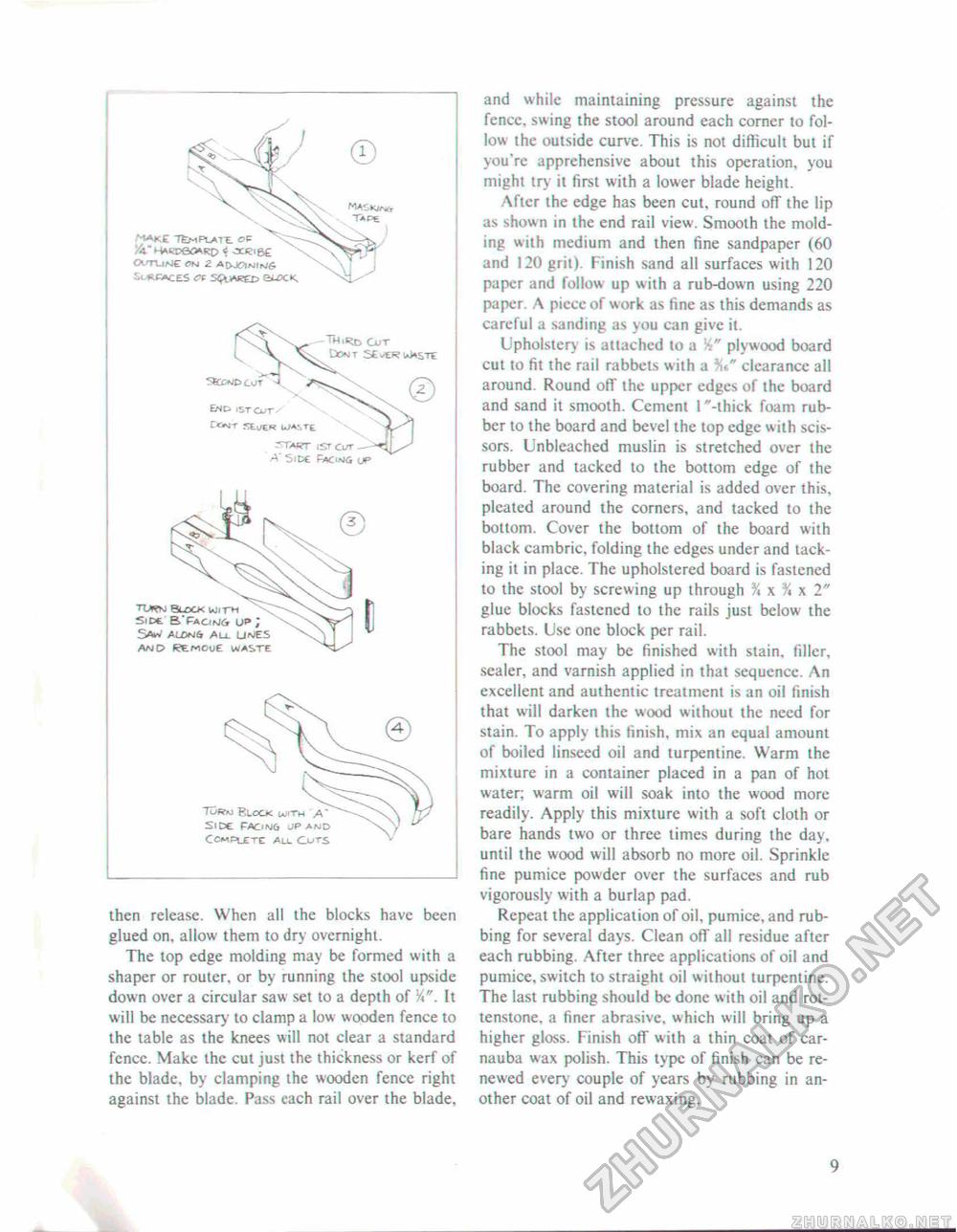

'-I'4KE ~ft>-vR A7TL op HAKVeO^Rp i OCR[&£ cutu^ie: £jn 2. AOJf?iniik/6 spaces of slfusbed block, TuWu Block with a' sldt faon6 up amd complete all cuts then release. When all the blocks have been glued on, allow them to dry overnight. The top edge molding may be formed with a shaper or router, or by running the stool upside down over a circular saw set to a depth of V*". It will be necessary to clamp a low wooden fence to the table as the knees will not clear a standard fence. Make the cut just the thickness or kerf of the blade, by clamping the wooden fence right against the blade. Pass each rail over the blade, and while maintaining pressure against the fence, swing the stool around each corner to follow the outside curve. This is not difficult but if you're apprehensive about this operation, you might try it first with a lower blade height. After the edge has been cut, round off the lip as shown in the end rail view. Smooth the molding with medium and then fine sandpaper (60 and ) 20 grit). Finish sand all surfaces with 120 paper and follow up with a rub-down using 220 paper, A piece of work as fine as this demands as careful a sanding as you can give it. Upholstery is attached to a V" plywood board cut to fit the rail rabbets with a clearance all around. Round off the upper edges of the board and sand it smooth. Cement 1 "-thick foam rubber to the board and bevel the top edge with scissors. Unbleached muslin is stretched over the rubber and tacked to the bottom edge of the board. The covering material is added over this, pleated around the corners, and tacked to the bottom. Cover the bottom of the board with black cambric, folding the edges under and lacking it in place. The upholstered board is fastened to the stool by screwing up through % \ % x 2" glue blocks fastened to the rails just below the rabbets. Use one block per rail. The stool may be finished with stain, filler, sealer, and varnish applied in that sequence. An excellent and authentic treatment is an oil finish that will darken the wood without ihe need for stain. To apply this finish, mix an equal amount of boiled linseed oil and turpentine. Warm the mixture in a container placed in a pan of hot water; warm oil will soak into the wood more readily. Apply this mixture with a soft cloth or bare hands two or three times during the day, until the wood will absorb no more oil. Sprinkle fine pumice powder over the surfaces and rub vigorously with a burlap pad. Repeat the application of oil, pumice, and rubbing for several days. Clean off all residue after each rubbing. After three applications of oil and pumice, switch to straight oil without turpentine. The last rubbing should be done with oil and rot-tenstone, a finer abrasive, which will bring up a higher gloss. Finish off with a thin coat of car-nauba wax polish. This type of finish can be renewed every couple of years by rubbing in another coat of oil and rewaxing. THIRD CUT dont sejer^ste ■attiMBCUT eno 1st cut. isr cm-A" 5iDE FTDCihg up TWO BLOCK with SI&E B'FACug& OP; S<W ALON& ALL U*iES aNO waste 9 |