Woodworker's Journal 101-Projects-for-Woodworkers, страница 239

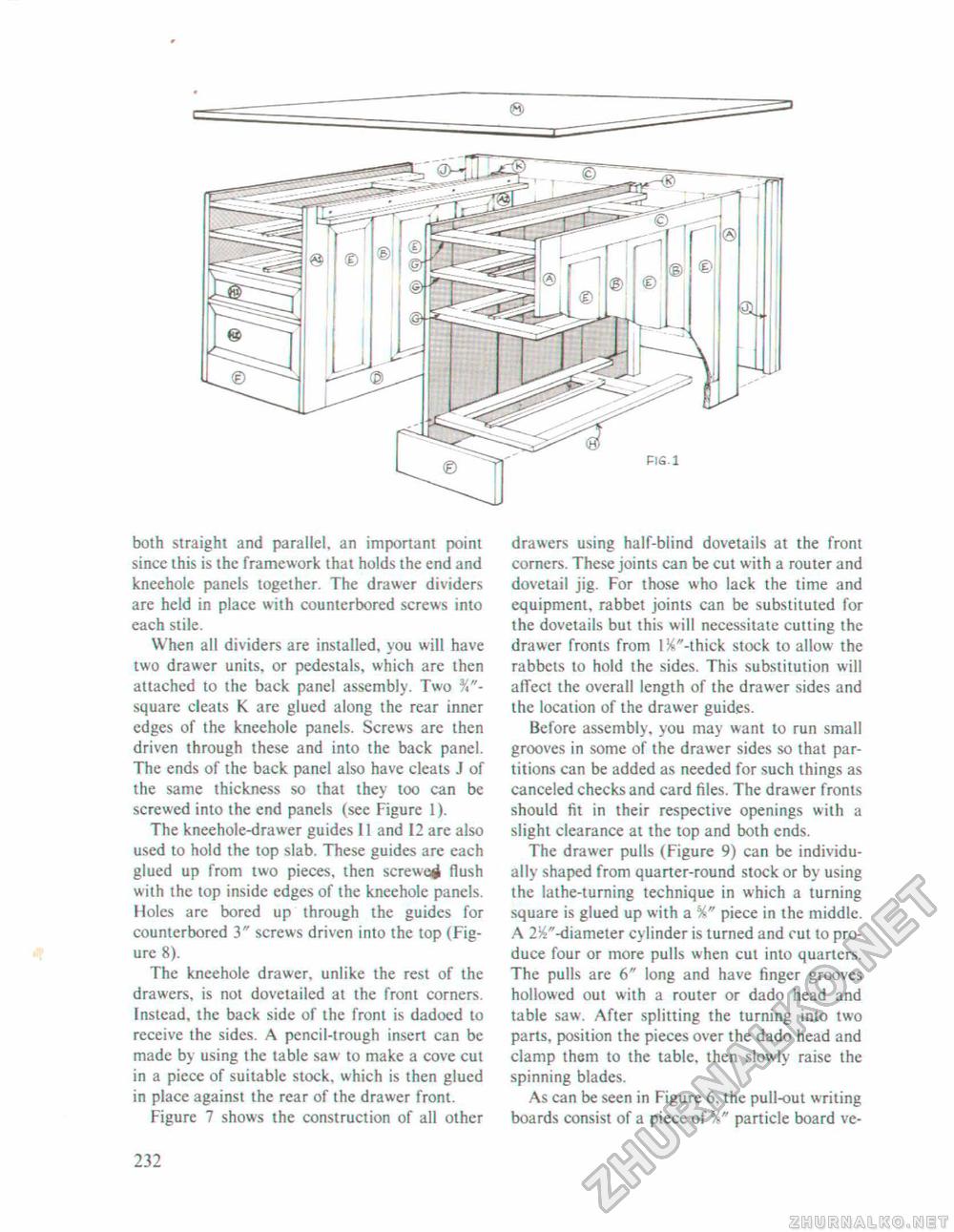

both straight and parallel, an important point since this is the framework that holds the end and kneehole panels together. The drawer dividers are held in place with counterbored screws into each stile. When all dividers are installed, you will have two drawer units, or pedestals, which are then attached to the back panel assembly. Two %"-square cleats K are glued along the rear inner edges of the kneehole panels. Screws are then driven through these and into the back panel. The ends of the back panel also have cleats J of the same thickness so that they too can be screwed into the end panels (see Figure 1). The kneehole-drawer guides 11 and 12 are also used to hold the top slab. These guides are each glued up from two pieces, then screwed (lush with the top inside edges of the kneehole panels. Holes are bored up through the guides for counterbored 3" screws driven into the top (Figure 8). The kneehole drawer, unlike the rest of the drawers, is not dovetailed at the front corners. Instead, the back side of the front is dadoed to receive the sides. A pencil-trough insert can be made by using the table saw to make a cove cut in a piece of suitable stock, which is then glued in place against the rear of the drawer front. Figure 7 shows the construction of all other drawers using half-biind dovetails at the front corners. These joints can be cut with a router and dovetail jig. For those who lack the time and equipment, rabbet joints can be substituted for the dovetails but this will necessitate cutting the drawer fronts from l/6"-lhick stock to allow the rabbets to hold the sides. This substitution will afTect the overall length of the drawer sides and the location of the drawer guides. Before assembly, you may want to run small grooves in some of the drawer sides so that partitions can be added as needed for such things as canceled checks and card files. The drawer fronts should fit in their respective openings with a slight clearance at the top and both ends. The drawer pulls (Figure 9) can be individually shaped from quarter-round stock or by using the lathe-turning technique in which a turning square is glued up with a %" piece in the middle. A 2&"-diameter cylinder is turned and cut to produce four or more pulls when cut into quarters. The pulls are 6" long and have finger grooves hollowed out with a router or dado head and table saw. After splitting the turning into two parts, position the pieces over the dado head and clamp them to the table, then slowly raise the spinning blades. As can be seen in Figure 6, the pull-out writing boards consist of a piece of %" particle board ve- 232 |