Woodworker's Journal 1981-5-6, страница 17

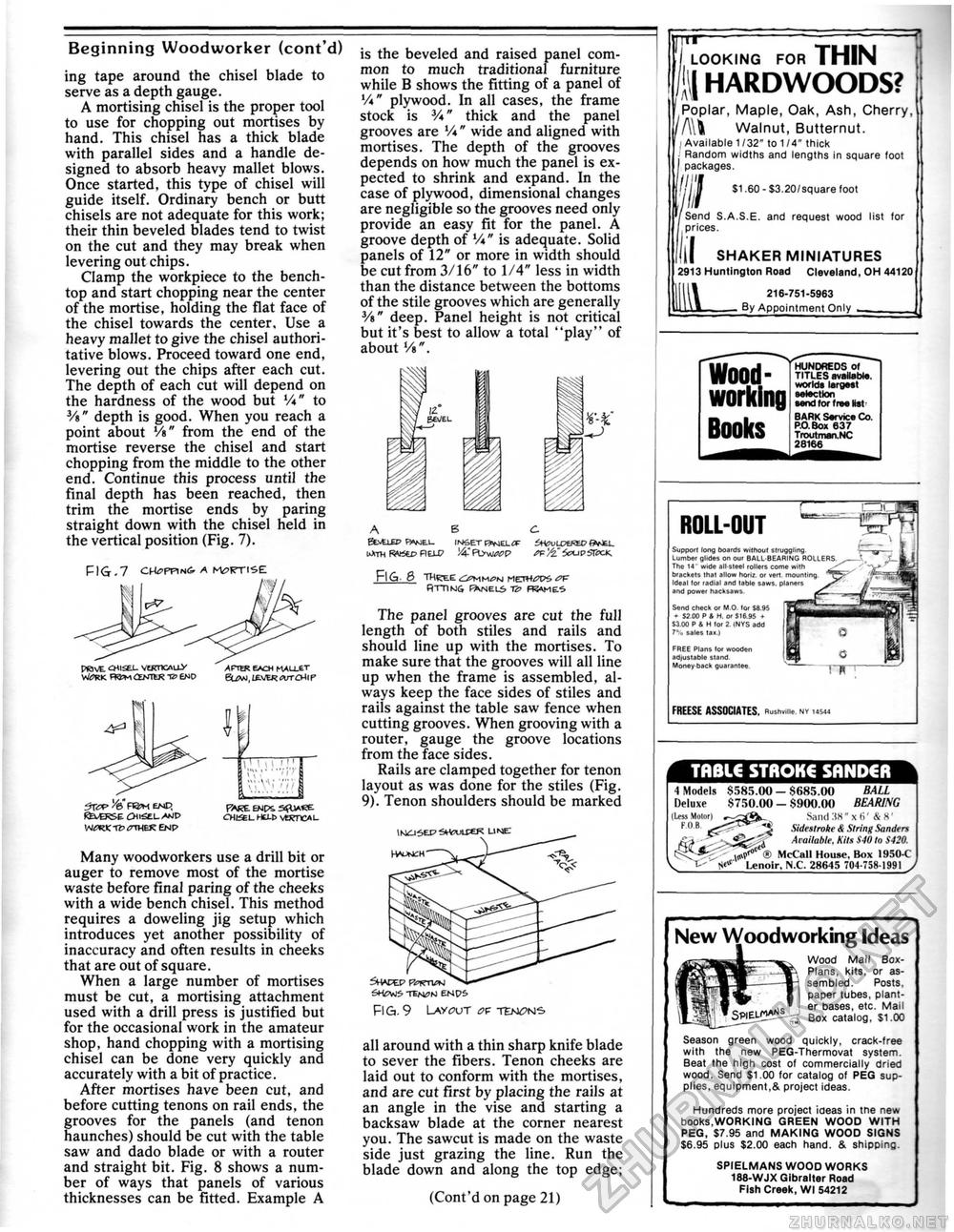

Beginning Woodworker (cont'd) ing tape around the chisel blade to serve as a depth gauge. A mortising chisel is the proper tool to use for chopping out mortises by hand. This chisel has a thick blade with parallel sides and a handle designed to absorb heavy mallet blows. Once started, this type of chisel will guide itself. Ordinary bench or butt chisels are not adequate for this work; their thin beveled blades tend to twist on the cut and they may break when levering out chips. Clamp the workpiece to the bench-top and start chopping near the center of the mortise, holding the flat face of the chisel towards the center. Use a heavy mallet to give the chisel authoritative blows. Proceed toward one end, levering out the chips after each cut. The depth of each cut will depend on the hardness of the wood but Vi" to 3/»" depth is good. When you reach a point about V»" from the end of the mortise reverse the chisel and start chopping from the middle to the other end. Continue this process until the final depth has been reached, then trim the mortise ends by paring straight down with the chisel held in the vertical position (Fig. 7). 3WP ENR REVERSE O4ISEL^WP 'rttPKX -tt> irmtx ENP i(; i| m !,;.l i'v y' s VW'|' Til 8 PARE ENPS. ssuwee CHUEt_ H£J-t> VDfTCAU Many woodworkers use a drill bit or auger to remove most of the mortise waste before final paring of the cheeks with a wide bench chisel. This method requires a doweling jig setup which introduces yet another possibility of inaccuracy and often results in cheeks that are out of square. When a large number of mortises must be cut, a mortising attachment used with a drill press is justified but for the occasional work in the amateur shop, hand chopping with a mortising chisel can be done very quickly and accurately with a bit of practice. After mortises have been cut, and before cutting tenons on rail ends, the grooves for the panels (and tenon haunches) should be cut with the table saw and dado blade or with a router and straight bit. Fig. 8 shows a number of ways that panels of various thicknesses can be fitted. Example A is the beveled and raised panel common to much traditional furniture while B shows the fitting of a panel of Vi" plywood. In all cases, the frame stock is 3/i" thick and the panel grooves are '/♦" wide and aligned with mortises. The depth of the grooves depends on how much the panel is expected to shrink and expand. In the case of plywood, dimensional changes are negligible so the grooves need only provide an easy fit for the panel. A groove depth of Vi" is adequate. Solid panels of 12" or more in width should be cut from 3/16" to 1/4" less in width than the distance between the bottoms of the stile grooves which are generally 3/s" deep. Panel height is not critical but it's best to allow a total "play" of about V»". A B bujuep rvoel- inset uatn rm5ep rej-p !4"r>w<w iWuLOtREP »N£L /T^'Spt-JPSIfcCK FIG- 8 THREE MEJH^PS RTT1KJG PANELS, TO R34MES The panel grooves are cut the full length of both stiles and rails and should line up with the mortises. To make sure that the grooves will all line up when the frame is assembled, always keep the face sides of stiles and rails against the table saw fence when cutting grooves. When grooving with a router, gauge the groove locations from the face sides. Rails are clamped together for tenon layout as was done for the stiles (Fig. 9). Tenon shoulders should be marked l-WJ^H" &K5VJS "TEN^N EN PS Fig. 9 uavcput of iwN6 all around with a thin sharp knife blade to sever the fibers. Tenon cheeks are laid out to conform with the mortises, and are cut first by placing the rails at an angle in the vise and starting a backsaw blade at the corner nearest you. The sawcut is made on the waste side just grazing the line. Run the blade down and along the top edge; (Cont'd on page 21) LOOKING FOR THIN Mj HARDWOODS? Poplar, Maple, Oak, Ash, Cherry, //\\i Walnut, Butternut. Available 1 /32" to 1 M" thick . Random widths and lengths in square foot packages. Illll $1.60 - $3.20/square foot Send S.A.S.E. and request wood list for prices. ( SHAKER MINIATURES 2913 Huntington Road Cleveland, OH 44120 IL 216-751-5963 . By Appointment Only Wood working Books HUNDREDS of TITLES available, worlds largest selection send (or free Hat BARK Service Co. P.O. Bo* 637 Trout man. NC 26166 FREESE ASSOCIATES. Rusnviii.. ny us« TABIC STROKC SRNDCR 4 Models $585.00 - $685.00 BALL Deluxe $750.00 - $900.00 BEARING (Lea Motor) Sand UK " x 6' & 8' Sides/robe & Siring Sanders Ai ailable, Kits S40 lo S420. McC'all House. Box 1950-C Lenoir, N.C. 28645 704-758 1991 > New Woodworking Ideas Wood Mail Box-Plans, kits, or assembled. Posts, paper tubes, planter bases, etc. Mail Box catalog, $1.00 Season green wood quickly, crack-free with the new PEG-Thermovat system. Beat the high cost of commercially dried wood. Send $1.00 for catalog of PEG supplies, equipments project ideas. Hundreds more project ideas in tne new books,WORKING GREEN WOOD WITH PEG, $7.95 and MAKING WOOD SIGNS $6.95 plus $2.00 each hand. & shipping. SPIELMANS WOOD WORKS 188-WJX Gibraltar Road Fish Creek, Wl 54212 FIG ■ 7 CHOPPING- -A r-VRTTSE PtaVE C81<EL- VOCTKALLy W«wc FWM Cents* -a> END AFTER £ACH HAU.ET 6UV0, ItVES fUTCMl p ROLL-OUT Support long boards without struggling. Lumber glides on our BALL BEARING ROLL The 14 wide all-steel rollers come with brackets that allow horiz. or vert, mounting. Ideal tor radial and table saws, planers and power hacksaws. Send check or M.O. lor $8.95 + S2.00 P & H. or $16.95 + S3.00 P 4 H tor 2. (NYS add 7% sales tax.) FREE Plans tor wooden adjustable stand. Money-back guarantee. |