Woodworker's Journal 1982-6-5, страница 20

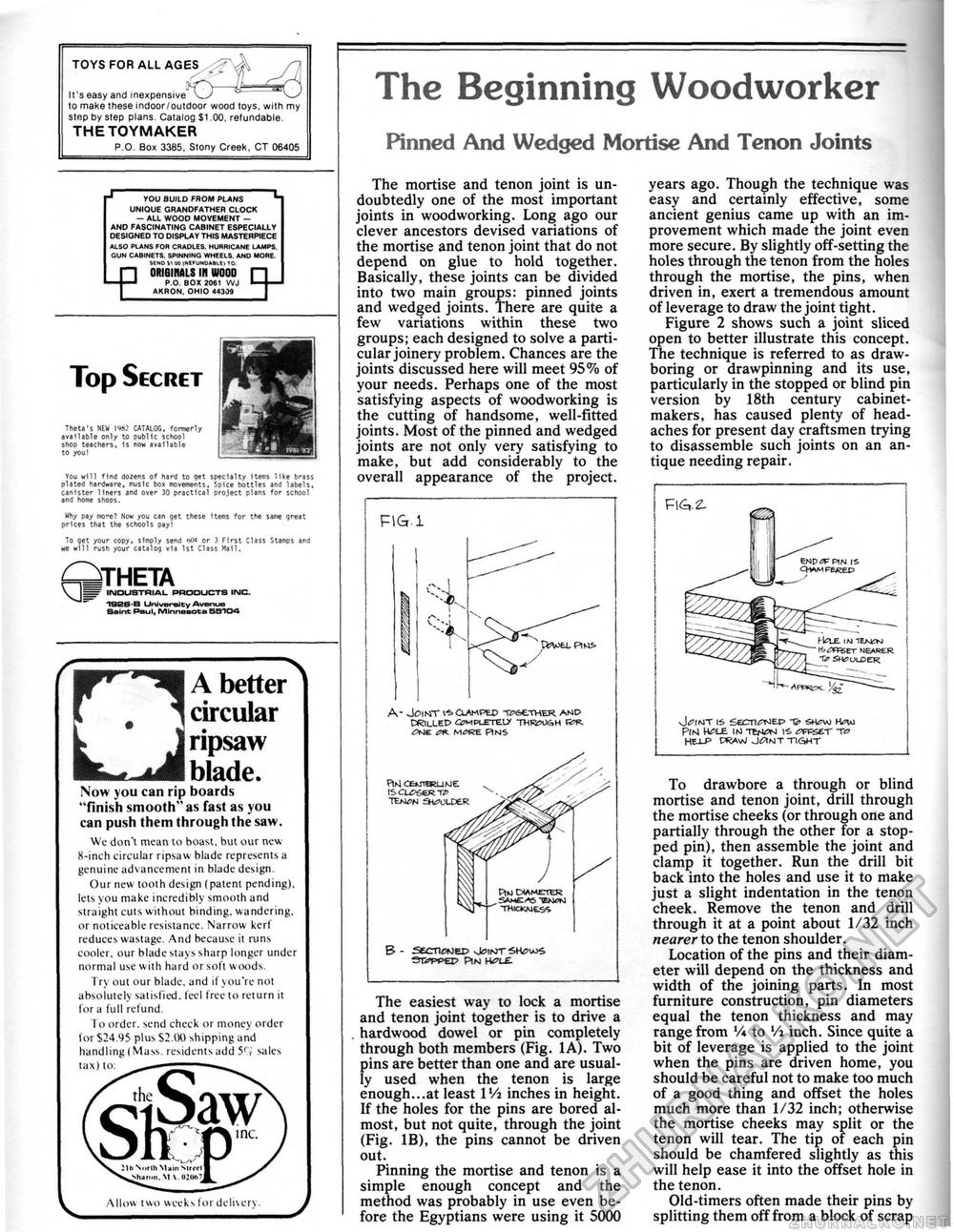

TOYS FOR ALL AGES It's easy and inexpensive to make these indoor/outdoor wood toys, with my step by step plans. Catalog $1 00. refundable. THETOYMAKER P.O. Box 3385, Stony Creek, CT 06405 * VOU BUILD FROM PLANS * UNIQUE GRANDFATHER CLOCK — ALL WOOD MOVEMENT — AND FASCINATING CABINET ESPECIALLY DESIGNED TO DISPLAY THIS MASTERPIECE ALSO PLANS FOR CRADLES. HURRICANE LAMPS. GUN CABINETS. SPINNING WHEELS. AND MORE. -£ SEND SS 00 (REFUNDABLE) TO ORIGINALS IN WOOD P.O. BOX 2061 WJ AKRON. OHIO 44309 Top Secret Theta's NEW l«»8J CATALOG, formerly available only to public school shop teachers, 1s now available to you! You will find dozens of hard to get specialty Items like brass plated hardware, music box movements. Spice bottles and labels, canister liners and over 30 practical project plans for school and home shops. Why pay mo-e? Now you can get these Items for the same great prices that the schools pay! To get your copy, simply send oO< or 3 First Class Stamps and we will rush your catalog via 1st Class Hall. 0THETA INDUSTRIAL PRODUCTS INC. 1926 B University Avenue Saint Peul, Minnesota SBlOa A better I # 1 circular ^ j ripsaw ■fen f iM blade. Now you can rip boards "finish smooth" as fast as you can push them through the saw. We don't mean to boast, but our new 8-inch circular ripsaw blade represents a genuine advancement in blade design. Our new tooth design (patent pending), lets you make incredibly smooth and straight cuts without binding, wandering, or noticeable resistance. Narrow kerf reduces wastage. And because it runs cooler, our blade slays sharp longer under normal use with hard or soft woods. Try out our blade, and if you're not absolutely satisfied, feel free to return it for a full refund To order, send check or money order for S24.95 plus $2.00 shipping and handling(Mass. residents add 5r< sales tax) to: The Beginning Woodworker Pinned And Wedged Mortise And Tenon Joints The mortise and tenon joint is undoubtedly one of the most important joints in woodworking. Long ago our clever ancestors devised variations of the mortise and tenon joint that do not depend on glue to hold together. Basically, these joints can be divided into two main groups: pinned joints and wedged joints. There are quite a few variations within these two groups; each designed to solve a particular joinery problem. Chances are the joints discussed here will meet 95% of your needs. Perhaps one of the most satisfying aspects of woodworking is the cutting of handsome, well-fitted joints. Most of the pinned and wedged joints are not only very satisfying to make, but add considerably to the overall appearance of the project. F1G.1 tfcVEL PtNS. A- Joint CLAMPED TI«.THER AND DRILLED OPMPL-ETE-Ly THK0OGH iXK M<*SE PINS PIN CEwisajwe ISCuPSeR-w TCWfN SCOLDER Ptu DIAMETER -TWcKNE-SiS. B - secnctOED JOINT st<?ppep pin The easiest way to lock a mortise and tenon joint together is to drive a hardwood dowel or pin completely through both members (Fig. 1A). Two pins are better than one and are usually used when the tenon is large enough...at least VA inches in height. If the holes for the pins are bored almost, but not quite, through the joint (Fig. IB), the pins cannot be driven out. Pinning the mortise and tenon is a simple enough concept and the method was probably in use even before the Egyptians were using it 5000 years ago. Though the technique was easy and certainly effective, some ancient genius came up with an improvement which made the joint even more secure. By slightly off-setting the holes through the tenon from the holes through the mortise, the pins, when driven in, exert a tremendous amount of leverage to draw the joint tight. Figure 2 shows such a joint sliced open to better illustrate this concept. The technique is referred to as draw-boring or drawpinning and its use, particularly in the stopped or blind pin version by 18th century cabinetmakers, has caused plenty of headaches for present day craftsmen trying to disassemble such joints on an antique needing repair. J^INT 16 SECTI^MEP SH^W H0\U PlM H^LE IN TEN<9N !<. £TT=S£T TO HE-LP C5AVJ JiflNT TIGHT To drawbore a through or blind mortise and tenon joint, drill through the mortise cheeks (or through one and partially through the other for a stopped pin), then assemble the joint and clamp it together. Run the drill bit back into the holes and use it to make just a slight indentation in the tenon cheek. Remove the tenon and drill through it at a point about 1/32 inch nearer to the tenon shoulder. Location of the pins and their diameter will depend on the thickness and width of the joining parts. In most furniture construction, pin diameters equal the tenon thickness and may range from Vi to Vi inch. Since quite a bit of leverage is applied to the joint when the pins are driven home, you should be careful not to make too much of a good thing and offset the holes much more than 1/32 inch; otherwise the mortise cheeks may split or the tenon will tear. The tip of each pin should be chamfered slightly as this will help ease it into the offset hole in the tenon. Old-timers often made their pins by splitting them off from a block of scrap |