Woodworker's Journal 1983-7-1, страница 37

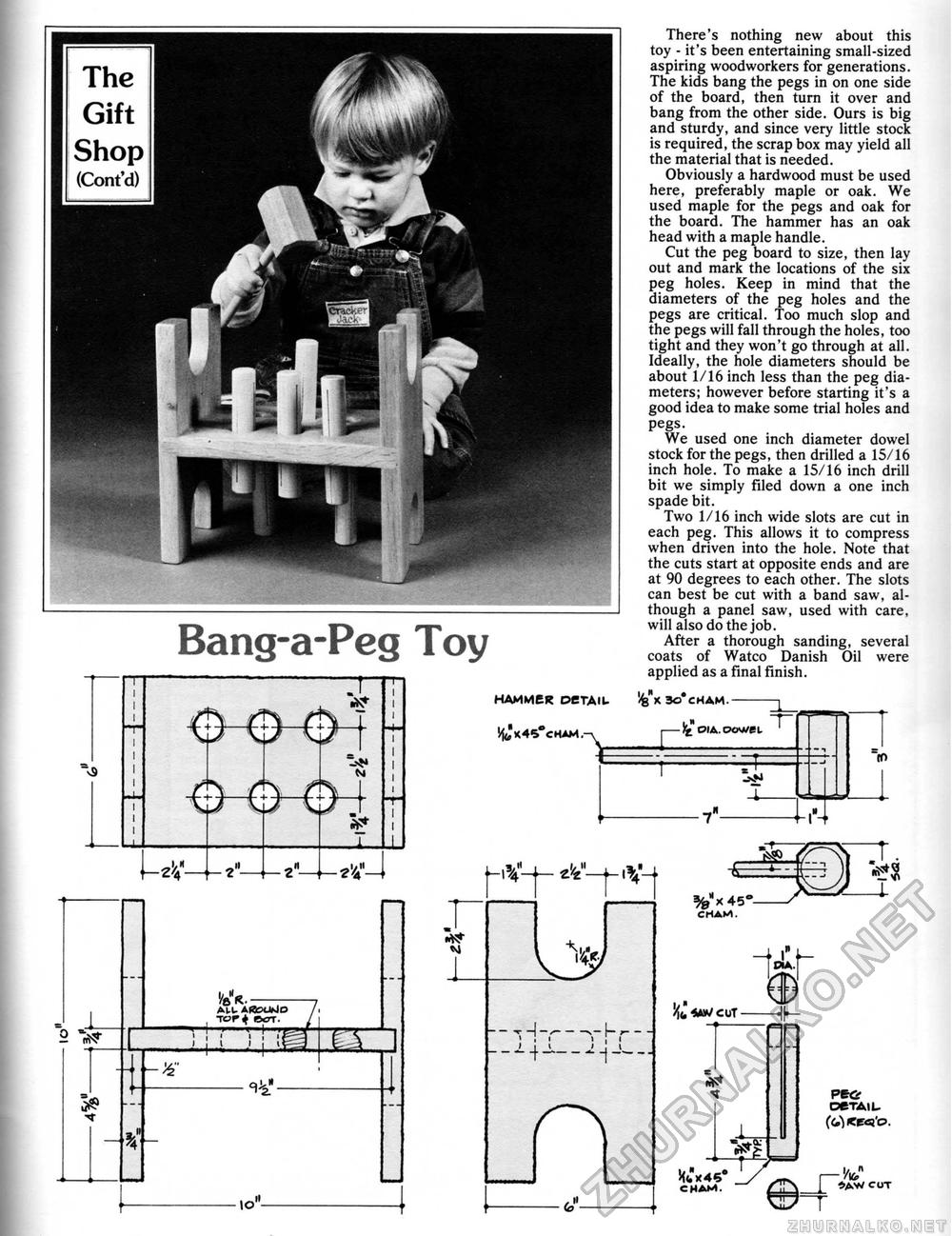

Bang-a-Peg Toy HAMMER DCTAlL pe<v OCTAlL ((.)Keet'c>. There's nothing new about this toy - it's been entertaining small-sized aspiring woodworkers for generations. The kids bang the pegs in on one side of the board, then turn it over and bang from the other side. Ours is big and sturdy, and since very little stock is required, the scrap box may yield all the material that is needed. Obviously a hardwood must be used here, preferably maple or oak. We used maple for the pegs and oak for the board. The hammer has an oak head with a maple handle. Cut the peg board to size, then lay out and mark the locations of the six peg holes. Keep in mind that the diameters of the peg holes and the pegs are critical. Too much slop and the pegs will fall through the holes, too tight and they won't go through at all. Ideally, the hole diameters should be about 1/16 inch less than the peg diameters; however before starting it's a good idea to make some trial holes and pegs. We used one inch diameter dowel stock for the pegs, then drilled a 15/16 inch hole. To make a 15/16 inch drill bit we simply filed down a one inch spade bit. Two 1/16 inch wide slots are cut in each peg. This allows it to compress when driven into the hole. Note that the cuts start at opposite ends and are at 90 degrees to each other. The slots can best be cut with a band saw, although a panel saw, used with care, will also do the job. After a thorough sanding, several coats of Watco Danish Oil were applied as a final finish. 3o*CHAM. -4- - CHAM. JjJ^w/cuT CAM. QU r-'V _ COT |