Woodworker's Journal 1983-7-2, страница 20

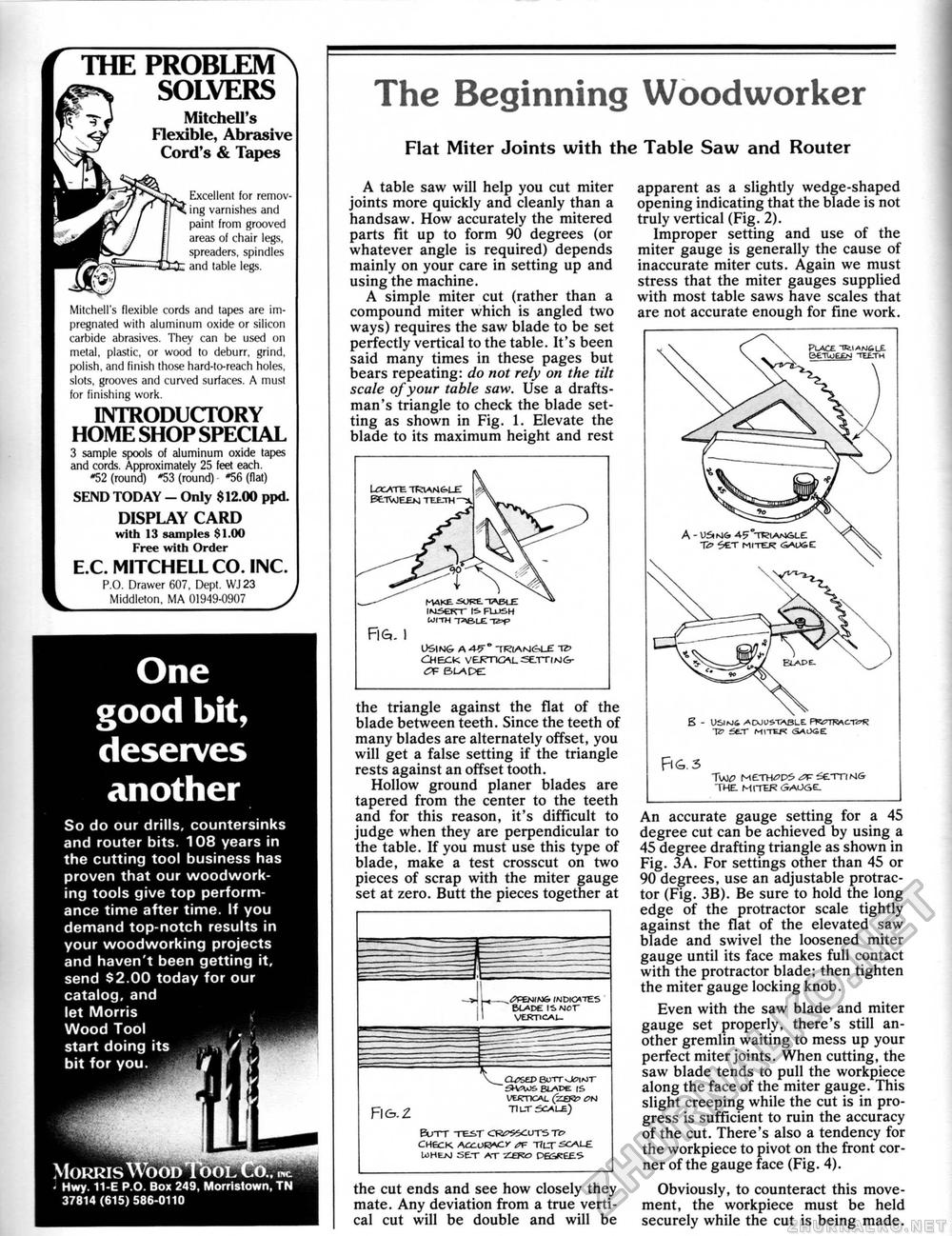

Mitchell's Flexible, Abrasive Cord's & Tapes Excellent for removing varnishes and paint from grooved areas of chair legs, spreaders, spindles and table legs. Mitchell's flexible cords and tapes are impregnated with aluminum oxide or silicon carbide abrasives. They can be used on metal, plastic, or wood to deburr, grind, polish, and finish those hard-to-reach holes, slots, grooves and curved surfaces. A must for finishing work. INTRODUCTORY HOME SHOP SPECIAL 3 sample spools of aluminum oxide tapes and cords. Approximately 25 feet each. •52 (round) "53 (round) "56 (flat) SEND TODAY - Only $12.00 ppd. DISPLAY CARD with 13 samples $1.00 Free with Order E.C. MITCHELL CO. INC. P.o. Drawer 607, Dept. WJ23 Middleton, MA 01949-0907 v good bit, deserves another So do our drills, countersinks and router bits. 108 years in the cutting tool business has proven that our woodworking tools give top performance time after time. If you demand top-notch results in your woodworking projects and haven't been getting it, send $2.00 today for our catalog, and let Morris Wood Tool (, v start doing its • bit for you. , * * THE PROBLEM^ SOLVERS The Beginning Woodworker Flat Miter Joints with the Table Saw and Router A table saw will help you cut miter joints more quickly and cleanly than a handsaw. How accurately the mitered parts fit up to form 90 degrees (or whatever angle is required) depends mainly on your care in setting up and using the machine. A simple miter cut (rather than a compound miter which is angled two ways) requires the saw blade to be set perfectly vertical to the table. It's been said many times in these pages but bears repeating: do not rely on the tilt scale of your table saw. Use a draftsman's triangle to check the blade setting as shown in Fig. 1. Elevate the blade to its maximum height and rest

the cut ends and see how closely they mate. Any deviation from a true vertical cut will be double and will be apparent as a slightly wedge-shaped opening indicating that the blade is not truly vertical (Fig. 2). Improper setting and use of the miter gauge is generally the cause of inaccurate miter cuts. Again we must stress that the miter gauges supplied with most table saws have scales that are not accurate enough for fine work. Place "H4ian6l£. BETWEEN -TEE.TH the triangle against the flat of the blade between teeth. Since the teeth of many blades are alternately offset, you will get a false setting if the triangle rests against an offset tooth. Hollow ground planer blades are tapered from the center to the teeth and for this reason, it's difficult to judge when they are perpendicular to the table. If you must use this type of blade, make a test crosscut on two pieces of scrap with the miter gauge set at zero. Butt the pieces together at B - USIM& ADJUSTABLE FRTTTS^CT^R TO StT MITEK SALXSE: R&.3 Tw MCTH&P5 fie-TTlMG THE. MITER <SAG&£- An accurate gauge setting for a 45 degree cut can be achieved by using a 45 degree drafting triangle as shown in Fig. 3A. For settings other than 45 or 90 degrees, use an adjustable protractor (Fig. 3B). Be sure to hold the long edge of the protractor scale tightly against the flat of the elevated saw blade and swivel the loosened miter gauge until its face makes full contact with the protractor blade; then tighten the miter gauge locking knob. Even with the saw blade and miter gauge set properly, there's still another gremlin waiting to mess up your perfect miter joints. When cutting, the saw blade tends to pull the workpiece along the face of the miter gauge. This slight creeping while the cut is in progress is sufficient to ruin the accuracy of the cut. There's also a tendency for the workpiece to pivot on the front corner of the gauge face (Fig. 4). Obviously, to counteract this movement, the workpiece must be held securely while the cut is being made. Butt test CRi5>S5CuTST£> CHECK ACC.oe*C-Y -rtLT^SCAI-E WHEN SET AT ZTO DBaREE.'S Fl&.Z CU>SEP BUTTvJtflMT 5H5WS BLADE: (S VERTICAL (.Z£U> <?N TILT SCALE) |

||||||||||||||||||||||||