Woodworker's Journal 1983-7-5, страница 59

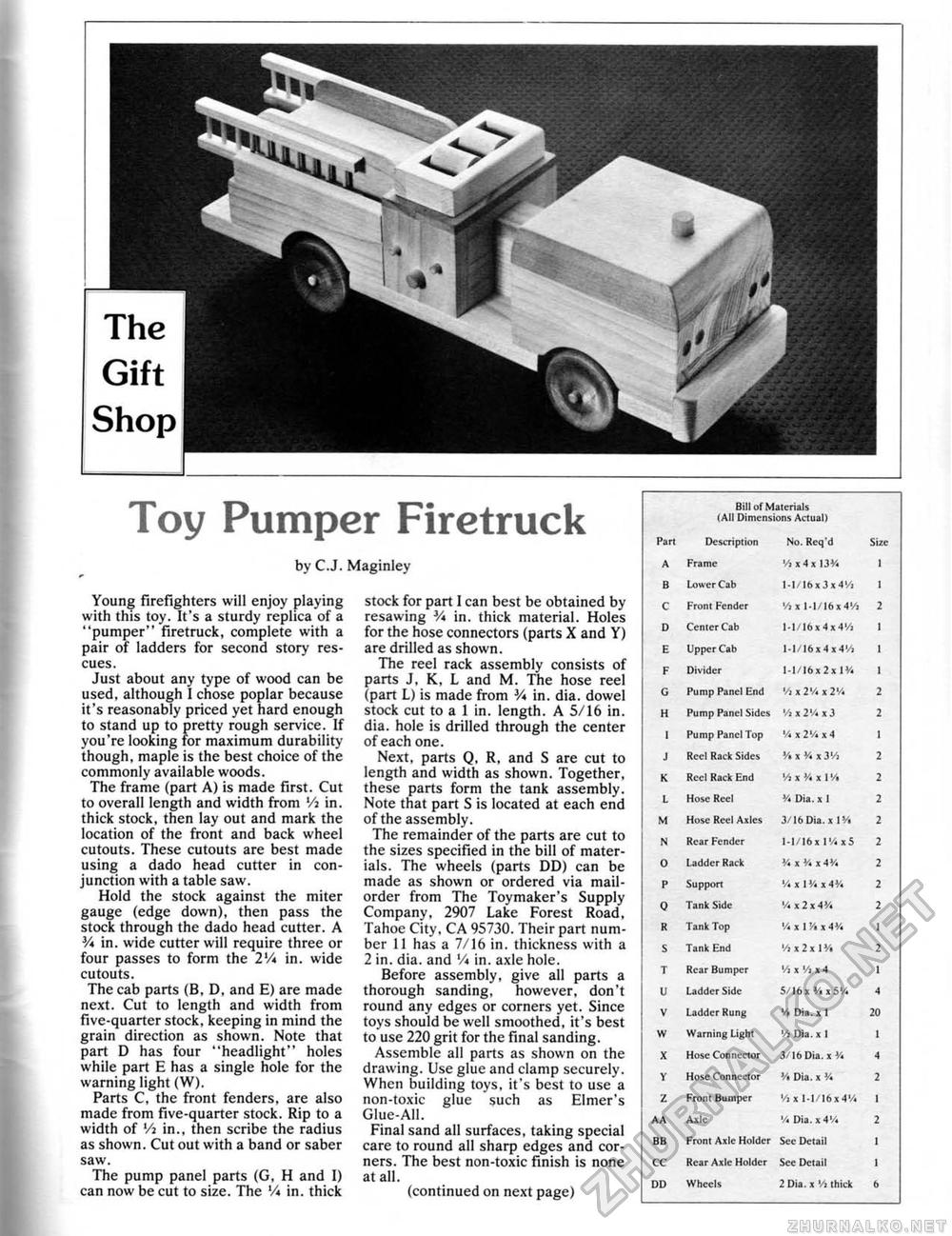

Toy Pumper Firetruck by C.J. Maginley Young firefighters will enjoy playing with this toy. It's a sturdy repiica of a "pumper" firetruck, complete with a pair of ladders for second story rescues. Just about any type of wood can be used, although I chose poplar because it's reasonably priced yet hard enough to stand up to pretty rough service. If you're looking for maximum durability though, mapie is the best choice of the commonly available woods. The frame (part A) is made first. Cut to overall length and width from Vi in, thick stock, then lay out and mark the location of the front and back wheel cutouts. These cutouts are best made using a dado head cutter in conjunction with a table saw. Hold the stock against the miter gauge (edge down), then pass the stock through the dado head cutter. A 3A in. wide cutter will require three or four passes to form the 2V* in, wide cutouts. The cab parts (B, D, and E) are made next. Cut to length and width from five-quarter stock, keeping in mind the grain direction as shown. Note that part D has four "headlight" holes while part E has a single hole for the warning light (W). Parts C, the front fenders, are also made from five-quarter stock. Rip to a width of '/i in., then scribe the radius as shown. Cut out with a band or saber saw. The pump panel parts (G, H and 1) can now be cut to size. The V* in. thick stock for part I can best be obtained by resawing % in. thick material. Holes for the hose connectors (parts X and Y) are drilled as shown. The reel rack assembly consists of parts J, K, L and M. The hose reel (part L) is made from 3A in. dia. dowel stock cut to a 1 in. length. A 5/16 in. dia. hole is drilled through the center of each one. Next, parts Q, R, and S are cut to length and width as shown. Together, these parts form the tank assembly. Note that part S is located at each end of the assembly. The remainder of the parts are cut to the sizes specified in the bill of materials. The wheels (parts DD) can be made as shown or ordered via mailorder from The Toymaker's Supply Company, 2907 Lake Forest Road, Tahoe City, CA 95730. Their part number 11 has a 7/16 in. thickness with a 2 in. dia. and 'A in. axle hole. Before assembly, give all parts a thorough sanding, however, don't round any edges or corners yet. Since toys should be well smoothed, it's best to use 220 grit for the final sanding. Assemble all parts as shown on the drawing. Use glue and clamp securely. When building toys, it's best to use a non-toxic glue such as Elmer's Glue-All. Final sand all surfaces, taking special care to round all sharp edges and corners. The best non-toxic finish is none at all. (continued on next page)

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||