Woodworker's Journal 1983-7-6, страница 58

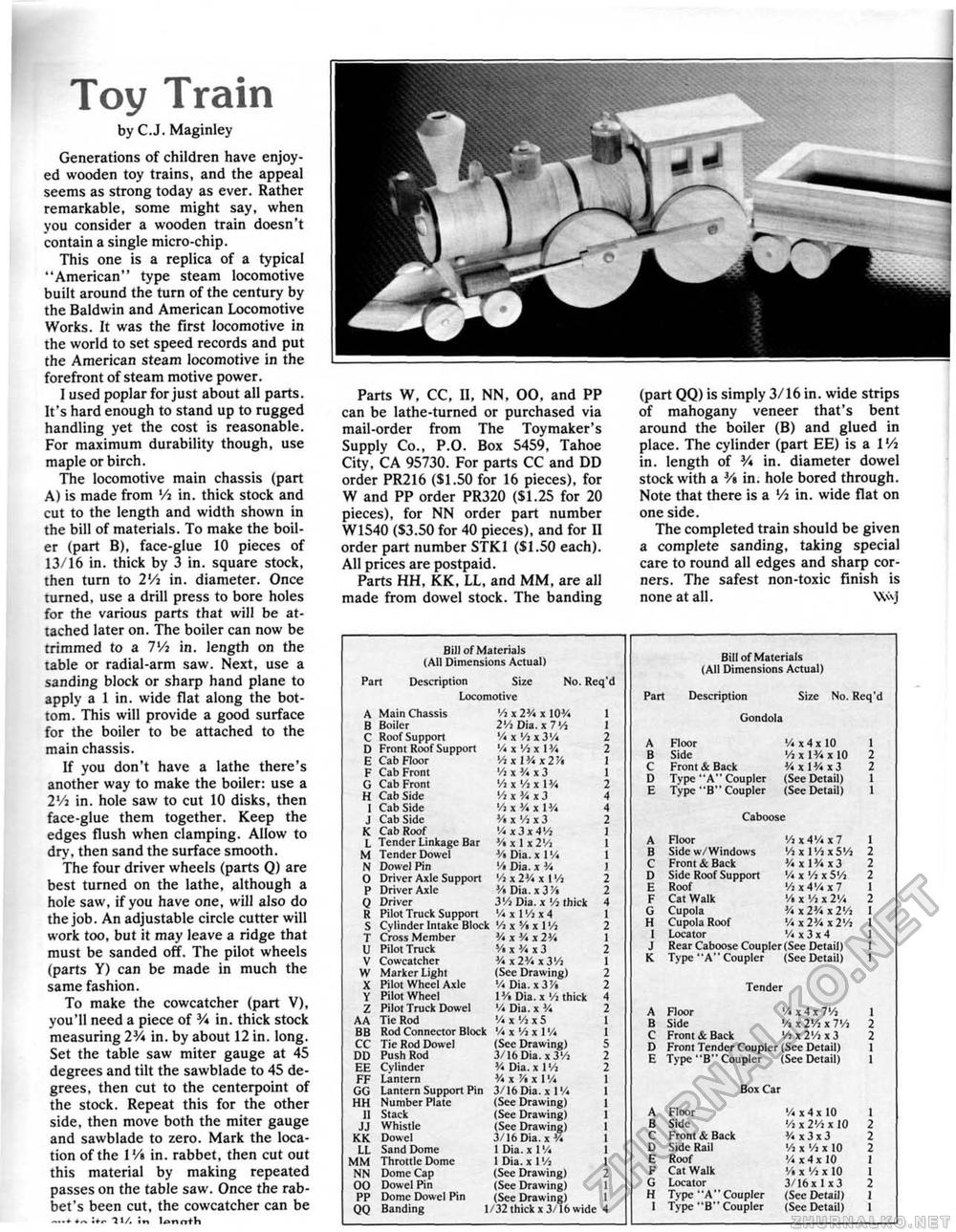

Toy Trainby C.J. Maginley Generations of children have enjoyed wooden toy trains, and the appeal seems as strong today as ever. Rather remarkable, some might say, when you consider a wooden train doesn't contain a single micro-chip. This one is a replica of a typical "American" type steam locomotive built around the turn of the century by the Baldwin and American Locomotive Works. It was the first locomotive in the world to set speed records and put the American steam locomotive in the forefront of steam motive power. I used poplar for just about all parts. It's hard enough to stand up to rugged handling yet the cost is reasonable. For maximum durability though, use maple or birch. The locomotive main chassis (part A) is made from Vi in. thick stock and cut to the length and width shown in the bill of materials. To make the boiler (part B), face-glue 10 pieces of 13/16 in. thick by 3 in. square stock, then turn to 2'/i in. diameter. Once turned, use a drill press to bore holes for the various parts that will be attached later on. The boiler can now be trimmed to a 7'/j in. length on the table or radial-arm saw. Next, use a sanding block or sharp hand plane to apply a 1 in. wide flat along the bottom. This will provide a good surface for the boiler to be attached to the main chassis. If you don't have a lathe there's another way to make the boiler: use a 2'/j in. hole saw to cut 10 disks, then face-glue them together. Keep the edges flush when clamping. Allow to dry, then sand the surface smooth. The four driver wheels (parts Q) are best turned on the lathe, although a hole saw, if you have one, will also do the job. An adjustable circle cutter will work too, but it may leave a ridge that must be sanded off. The pilot wheels (parts Y) can be made in much the same fashion. To make the cowcatcher (part V), you'll need a piece of ¥* in. thick stock measuring 2¥* in. by about 12 in. long. Set the table saw miter gauge at 45 degrees and tilt the sawblade to 45 degrees, then cut to the centerpoint of the stock. Repeat this for the other side, then move both the miter gauge and sawblade to zero. Mark the location of the 1'/» in. rabbet, then cut out this material by making repeated passes on the table saw. Once the rabbet's been cut. the cowcatcher can be . ... t i/, it, 1.>T-I nt H Parts W, CC, II, NN. 00, and PP can be lathe-turned or purchased via mail-order from The Toy maker's Supply Co., P.O. Box 5459, Tahoe City. CA 95730. For parts CC and DD order PR216 ($1.50 for 16 pieces), for W and PP order PR320 ($1.25 for 20 pieces), for NN order part number W1540 ($3.50 for 40 pieces), and for II order part number STK1 ($1.50 each). All prices are postpaid. Parts HH. KK, LL, and MM, are all made from dowel stock. The banding Bill of Materials (All Dimensions Actual) Part Description Size No, Req'd Locomotive Part Description Size No, Req'd Locomotive

(part QQ) is simply 3/16 in. wide strips of mahogany veneer that's bent around the boiler (B) and glued in place. The cylinder (part EE) is a I'/i in. length of ¥* in. diameter dowel stock with a ¥* in. hole bored through. Note that there is a Vi in. wide fiat on one side. The completed train should be given a complete sanding, taking special care to round all edges and sharp corners. The safest non-toxic finish is none at all. W\J Bill of Materials {All Dimensions Actual} Part Description Size No. Req'd Gondola A Floor '/«x4xf0 ! B Side Vt x IV, x 10 2 C Front & Back V, x 1 y,x3 2 D Type "A" Coupler {See Detail) 1 E Type "B" Coupler (See Detail) I Caboose A Floor '/«x4xf0 ! B Side Vt x IV, x 10 2 C Front & Back V, x 1 y,x3 2 D Type "A" Coupler {See Detail) 1 E Type "B" Coupler (See Detail) I Caboose

Tender Tender A Floor Vi x 4 x 7'/i i B Side Vi x 2'A x 7'/j 2 C Front & Back Vixl'A x3 2 D Front Tender Coupler (See Detail) 1 E Type "B" Coupler (See Detail) 1 Box Car Box Car

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||