Woodworker's Journal 1984-8-2, страница 40

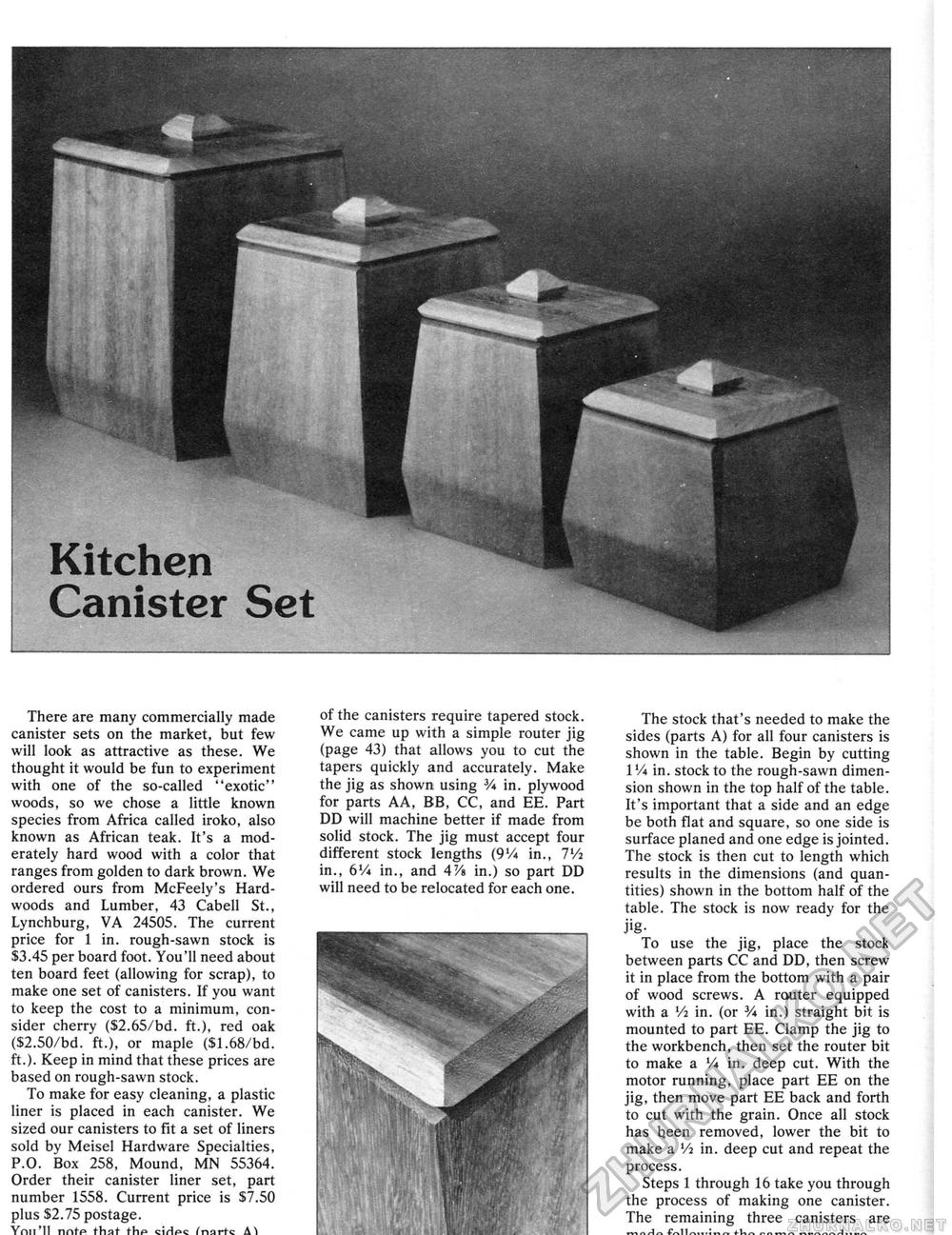

There are many commercially made canister sets on the market, but few will look as attractive as these. We thought it would be fun to experiment with one of the so-called "exotic" woods, so we chose a little known species from Africa called iroko, also known as African teak. It's a moderately hard wood with a color that ranges from golden to dark brown. We ordered ours from McFeely's Hardwoods and Lumber, 43 Cabell St., Lynchburg, VA 24505. The current price for I in. rough-sawn stock is $3.45 per board foot. You'll need about ten board feet (allowing for scrap), to make one set of canisters. If you want to keep the cost to a minimum, consider cherry ($2.65/bd. ft.), red oak ($2.50/bd. ft.), or maple ($1.68/bd. ft.). Keep in mind that these prices are based on rough-sawn stock. To make for easy cleaning, a plastic liner is placed in each canister. We sized our canisters to fit a set of liners sold by Meisel Hardware Specialties, P.O. Box 258, Mound, MN 55364. Order their canister liner set, part number 1558. Current price is $7.50 plus $2.75 postage. Ynrt'll nntp that tfip cidpe fnai-te A V The stock that's needed to make the sides (parts A) for all four canisters is shown in the table. Begin by cutting 1 Vi in. stock to the rough-sawn dimension shown in the top half of the table. It's important that a side and an edge be both flat and square, so one side is surface planed and one edge is jointed. The stock is then cut to length which results in the dimensions (and quantities) shown in the bottom half of the table. The stock is now ready for the jig' To use the jig, place the stock between parts CC and DD, then screw it in place from the bottom with a pair of wood screws. A router equipped with a '/i in. (or 3A in.) straight bit is mounted to part EE. Clamp the jig to the workbench, then set the router bit to make a V* in. deep cut. With the motor running, place part EE on the jig, then move part EE back and forth to cut with the grain. Once all stock has been removed, lower the bit to make a V2 in, deep cut and repeat the process. Steps 1 through 16 take you through the process of making one canister. The remaining three canisters are of the canisters require tapered stock. We came up with a simple router jig (page 43) that allows you to cut the tapers quickly and accurately. Make the jig as shown using SA in. plywood for parts AA, BB, CC, and EE. Part DD will machine better if made from solid stock. The jig must accept four different stock lengths (9V* in., 7Vi in., 6V* in., and 4V» in.) so part DD will need to be relocated for each one. |