Woodworker's Journal 1984-8-2, страница 41

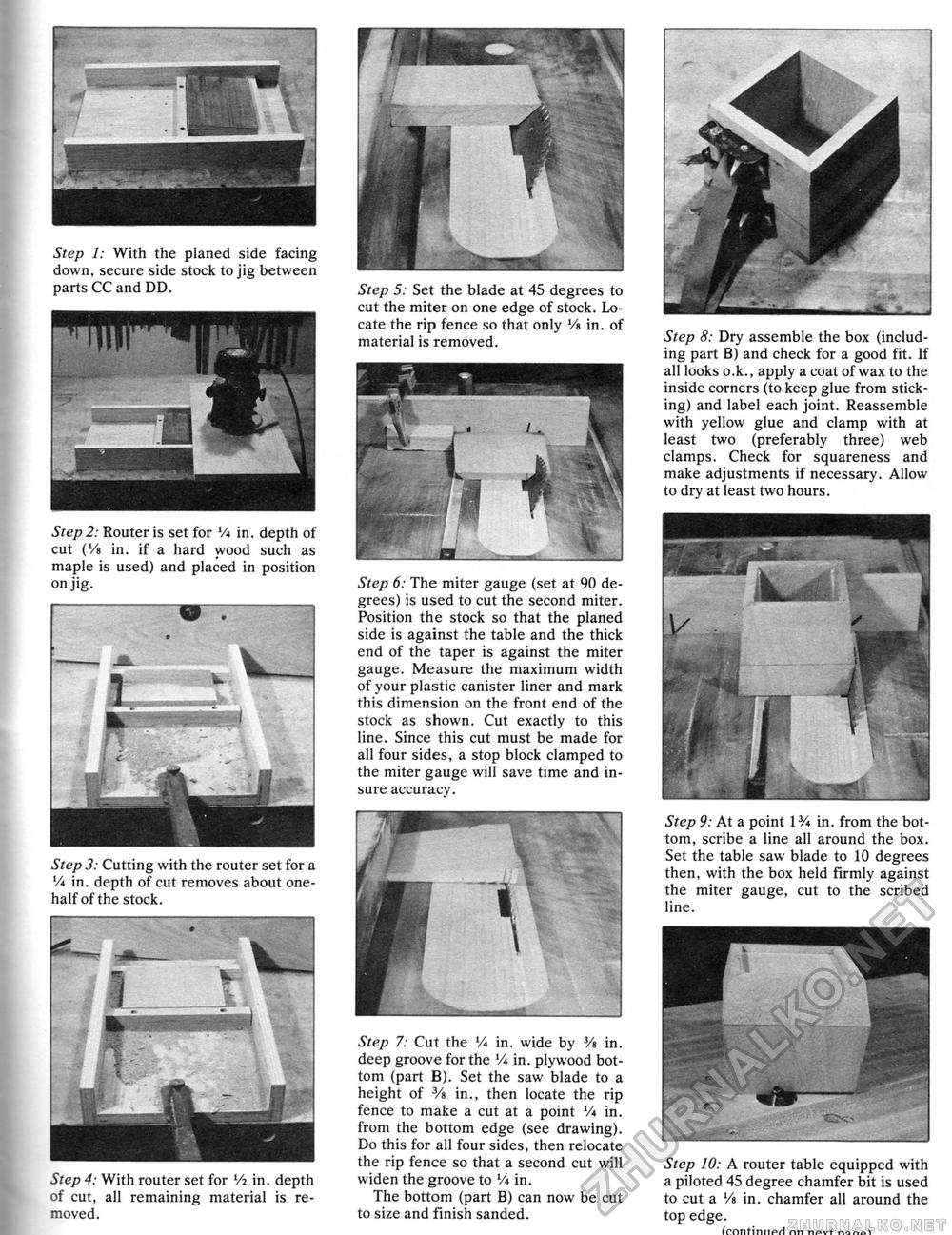

Step 1: With the planed side facing down, secure side stock to jig between parts CC and DD. Step 2: Router is set for Vi in. depth of cut (Vs in. if a hard wood such as maple is used) and placed in position on jig. Step 3: Cutting with the router set for a V* in. depth of cut removes about one-half of the stock. Step 4; With router set for V2 in. depth of cut, all remaining material is removed. Step 5: Set the blade at 45 degrees to cut the miter on one edge of stock. Locate the rip fence so that only V» in. of material is removed. Step 6: The miter gauge (set at 90 degrees) is used to cut the second miter. Position the stock so that the planed side is against the table and the thick end of the taper is against the miter gauge. Measure the maximum width of your plastic canister liner and mark this dimension on the front end of the stock as shown. Cut exactly to this line. Since this cut must be made for all four sides, a stop block clamped to the miter gauge will save time and insure accuracy. Step 7: Cut the Vi in. wide by 3/s in. deep groove for the Vi in. plywood bottom (part B). Set the saw blade to a height of 3/t in., then locate the rip fence to make a cut at a point V* in. from the bottom edge (see drawing). Do this for all four sides, then relocate the rip fence so that a second cut will widen the groove to Vi in. The bottom (part B) can now be cut to size and finish sanded. P ygff ••-■■ _,___ Step 8: Dry assemble the box (including part B) and check for a good fit. If all looks o.k., apply a coat of wax to the inside corners (to keep glue from sticking) and label each joint. Reassemble with yellow glue and clamp with at least two (preferably three) web clamps. Check for squareness and make adjustments if necessary. Allow to dry at least two hours. Step 9: At a point IV* in. from the bottom, scribe a line all around the box. Set the table saw blade to 10 degrees then, with the box held firmly against the miter gauge, cut to the scribed line. Step 10: A router table equipped with a piloted 45 degree chamfer bit is used to cut a Vt in. chamfer all around the top edge. Icnntimipfl nn npvt noou) |