Woodworker's Journal 1984-8-3, страница 11

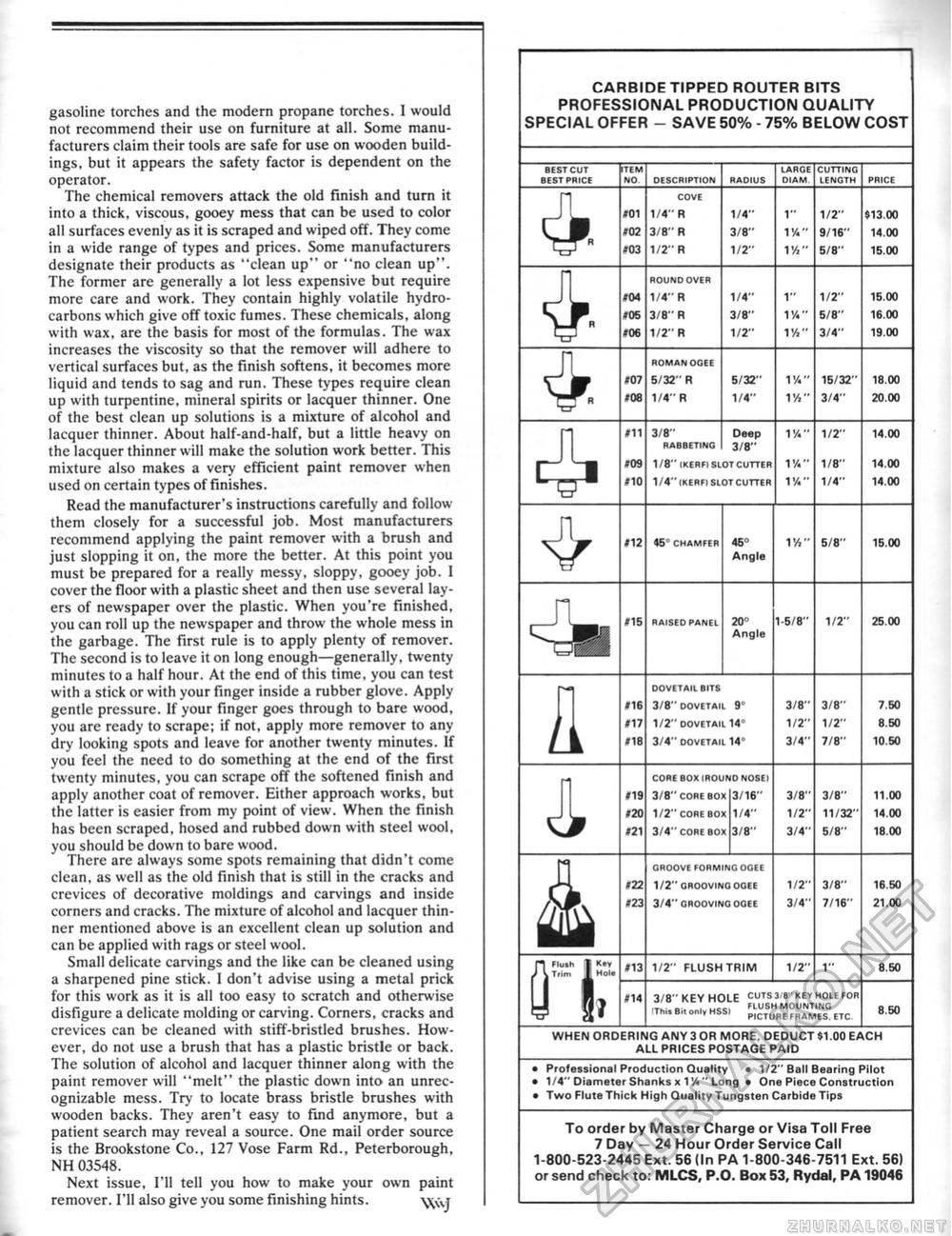

gasoline torches and the modern propane torches. 1 would not recommend their use on furniture at all. Some manufacturers claim their tools are safe for use on wooden buildings, but it appears the safety factor is dependent on the operator. The chemical removers attack the old finish and turn it into a thick, viscous, gooey mess that can be used to color all surfaces evenly as it is scraped and wiped off. They come in a wide range of types and prices. Some manufacturers designate their products as "clean up" or "no clean up". The former are generally a lot less expensive but require more care and work. They contain highly volatile hydrocarbons which give off toxic fumes. These chemicals, along with wax, are the basis for most of the formulas. The wax increases the viscosity so that the remover will adhere to vertical surfaces but, as the finish softens, it becomes more liquid and tends to sag and run. These types require clean up with turpentine, mineral spirits or lacquer thinner. One of the best clean up solutions is a mixture of alcohol and lacquer thinner. About half-and-half, but a little heavy on the lacquer thinner will make the solution work better. This mixture also makes a very efficient paint remover when used on certain types of finishes. Read the manufacturer's instructions carefully and follow them closely for a successful job. Most manufacturers recommend applying the paint remover with a brush and just slopping it on, the more the better. At this point you must be prepared for a really messy, sloppy, gooey job. I cover the floor with a plastic sheet and then use several layers of newspaper over the plastic. When you're finished, you can roll up the newspaper and throw the whole mess in the garbage. The first rule is to apply plenty of remover. The second is to leave it on long enough—generally, twenty minutes to a half hour. At the end of this time, you can test with a stick or with your finger inside a rubber glove. Apply gentle pressure. If your finger goes through to bare wood, you are ready to scrape; if not, apply more remover to any dry looking spots and leave for another twenty minutes. If you feel the need to do something at the end of the first twenty minutes, you can scrape off the softened finish and apply another coat of remover. Either approach works, but the latter is easier from my point of view. When the finish has been scraped, hosed and rubbed down with steel wool, you should be down to bare wood. There are always some spots remaining that didn't come clcan, as well as the old finish that is still in the cracks and crevices of decorative moldings and carvings and inside corners and cracks. The mixture of alcohol and lacquer thinner mentioned above is an excellent clean up solution and can be applied with rags or steel wool. Small delicate carvings and the like can be cleaned using a sharpened pine stick, 1 don't advise using a metal prick for this work as it is all too easy to scratch and otherwise disfigure a delicate molding or carving. Corners, cracks and crevices can be cleaned with stiff-bristled brushes. However, do not use a brush that has a plastic bristle or back. The solution of alcohol and lacquer thinner along with the paint remover will "melt" the plastic down into an unrecognizable mess. Try to locate brass bristle brushes with wooden backs. They aren't easy to find anymore, but a patient search may reveal a source. One mail order source is the Brookstone Co., 127 Vose Farm Rd., Peterborough, NH 03548. Next issue, I'll tell you how to make your own paint remover. I'll also give you some finishing hints. CARBIDE TIPPED ROUTER BITS PROFESSIONAL PRODUCTION QUALITY SPECIAL OFFER - SAVE 50% - 75% BELOW COST BEST CUT BEST PRICE ITEM MO DESCRIPTION LARGE DIAM. CUTTING LENGTH 101 #02 #03 COVE 1/4" R 3/8" R 1/2" R 1/4" 3/8" 1/2" 1" IV 1 'A' 1/2" 9/16" 5/8" ■v* #04 #06 #06 ROUND OVER 1/4" R 3/8" R 1/2" R 1/4" 3/8" 1/2" 1" IV IV 1/2" 5/8" 3/4" #07 #08 ROMAN OGEE 5/32" R 1/4" R 5/32" 1/4" 114" 1V4' 15/32" 3/4" #11 #09 #10 3/8" RABBETING Deep 3/8" 1/8" [KERFI SLOT CUTTER 1/4" IKIRFI SLOT CUTTER 114* 1%' IV 1/2" 1/8" 1/4" <r #12 45° CHAMFER 45° Angle 1V 5/8" rt #15 RAISED PANEL 20° Angle 1-5/8" 1/2" H #16 #17 #18 DOVETAIL BITS 3/8" DOVETAIL 9" 1/2" DOVETAIL 14" 3/4" DOVETAIL 14" 3/8" 1/2" 3/4" 3/8" 1/2" 7/8" CORE BOX [ROUND NOSEI #19 #20 #21 3/B" CORE BOX 1/2" CORE BOX 3/4" CORE BOX 3/16" 1/4" 3/0" 3/B' 1/2' 3/4' 3/8" 11/32" 5/B" 4 #22 #23 GROOVE FORMING OGEE 1/2" GROOVING OGEE 3/4" GROOVING OGEE 1/2' 3/4' 3/B" 7/16" a Fluth 1 K«y Trim 1 Holi #13 1/2" FLUSH TRIM 1/2" 1" J #14 3/B" KEY HOLE CUTS 3'8" Kev H0>-E F0R rr,. n . uee, FLUSH MOUNTING B,. only HSS) PICTURE FRAMES. ETC. 8.50 WHEN ORDERING ANY30R MORE, DEDUCT $1.00 EACH ALL PRICES POSTAGE PAID • Professional Production Quality • 1/2" Ball Bearing Pilot • 1/4" Diameter Shanks x 1%" Long • One Piece Construction • Two Flute Thick High Quality Tungsten Carbide Tips To order by Master Charge or Visa Toll Free 7 Day — 24 Hour Order Service Call 1-800-523-2445 Ext. 56 (In PA 1-800-346-7511 Ext. 56) or send check to: MLCS, P.O. Box 53, Rydal, PA 19046 |