Woodworker's Journal 1984-8-3, страница 14

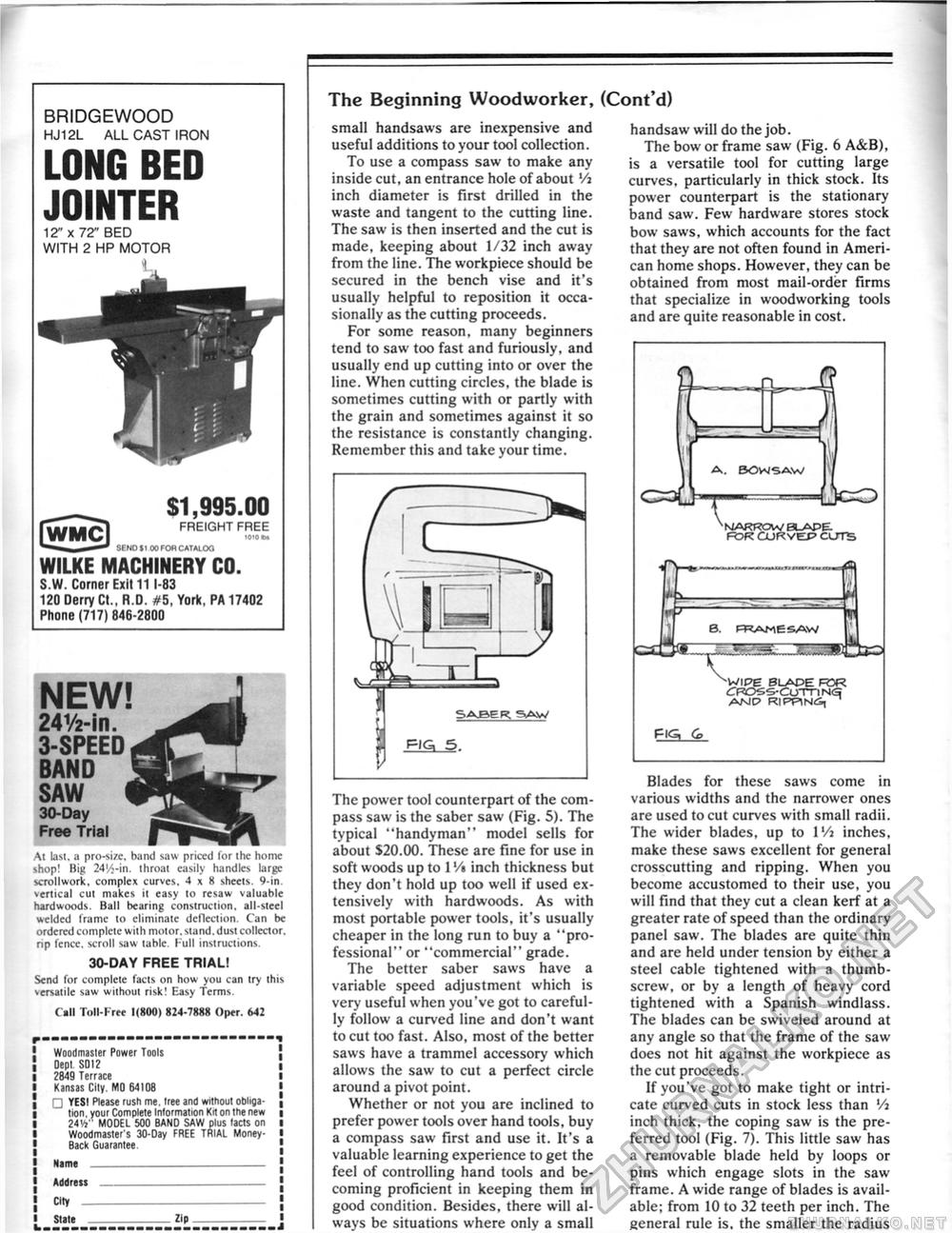

BRIDGEWOOD HJ12L ALL CAST IRON LONG BED JOINTER12" x 72" BED WITH 2 HP MOTOR WMCI $1,995.00 FREIGHT FREE 1010 bt SEND Si 00 FOR CATALOG WILKE MACHINERY CO. S.W. Corner Exit 111-83 120 Derry Ct„ R.D. #5, York, PA 17402 Phone (717) 846-2800 NEW! 241/2-in. 3-SPEED BAND SAW 30-Day Free Trial At last, u pro-sire, band saw priced for the home shop! Big 24!A-in. throat easily handles large scrollwork, complex curves. 4x8 sheets. 9-in vertical cut makes it easy to resaw valuable hardwoods. Ball bearing construction, all-steel welded frame to eliminate deflection. Can be ordered complete with motor, stand, dust collector, rip fence, scroll saw table. Kull instructions. 30-DAY FREE TRIAL! Send for complete facts on how you can try this versatile saw without risk! Easy Terms. ( all Toll-Free 1(800) 824-7888 Oper. 642 Woodmasler Power Tools Oept SO 12 2849 Terrace Kansas Cily. MO 64108 □ YESI Please rush me. tree and without obligation. your Complete Information Kit on the new 24W" MODEL 500 BAND SAW plus lacts on Woodmaster's 30-Day FREE TRIAL Money-Back Guarantee Name _ Address City _ State _ Zip The Beginning Woodworker, (Cont'd) small handsaws are inexpensive and useful additions to your tool collection. To use a compass saw to make any inside cut, an entrance hole of about Vi inch diameter is first drilled in the waste and tangent to the cutting line. The saw is then inserted and the cut is made, keeping about 1/32 inch away from the line. The workpiece should be secured in the bench vise and it's usually helpful to reposition it occasionally as the cutting proceeds. For some reason, many beginners tend to saw too fast and furiously, and usually end up cutting into or over the line. When cutting circles, the blade is sometimes cutting with or partly with the grain and sometimes against it so the resistance is constantly changing. Remember this and take your time. The power tool counterpart of the compass saw is the saber saw (Fig. 5). The typical "handyman" model sells for about $20.00. These are fine for use in soft woods up to 1'/»inch thickness but they don't hold up too well if used extensively with hardwoods. As with most portable power tools, it's usually cheaper in the long run to buy a "professional" or "commercial" grade. The better saber saws have a variable speed adjustment which is very useful when you've got to carefully follow a curved line and don't want to cut too fast. Also, most of the better saws have a trammel accessory which allows the saw to cut a perfect circle around a pivot point. Whether or not you are inclined to prefer power tools over hand tools, buy a compass saw first and use it. It's a valuable learning experience to get the feel of controlling hand tools and becoming proficient in keeping them in good condition. Besides, there will always be situations where only a small handsaw will do the job. The bow or frame saw (Fig. 6 A&B), is a versatile tool for cutting large curves, particularly in thick stock. Its power counterpart is the stationary band saw. Few hardware stores stock bow saws, which accounts for the fact that they are not often found in American home shops. However, they can be obtained from most mail-order firms that specialize in woodworking tools and are quite reasonable in cost. (jcO NARROWBLAPE-f=OK CURVEP CUTS 6. FRAMESAW S^ssL__£ WIPE BLAPE FOR CROSS-COTTINS AMP RIPPING PIG, Co Blades for these saws come in various widths and the narrower ones are used to cut curves with small radii. The wider blades, up to l'/j inches, make these saws excellent for general crosscutting and ripping. When you become accustomed to their use, you will find that they cut a clean kerf at a greater rate of speed than the ordinary panel saw. The blades are quite thin and are held under tension by either a steel cable tightened with a thumbscrew, or by a length of heavy cord tightened with a Spanish windlass. The blades can be swiveled around at any angle so that the frame of the saw does not hit against the workpiece as the cut proceeds. If you've got to make tight or intricate curved cuts in stock less than Vi inch thick, the coping saw is the preferred tool (Fig. 7). This little saw has a removable blade held by loops or pins which engage slots in the saw frame. A wide range of blades is available; from 10 to 32 teeth per inch. The general rule is, the smaller the radius |